The Power of Textile Transfer Machines

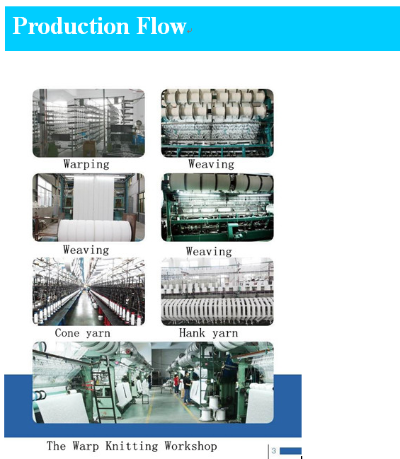

In the realm of textile production, the power of transfer machines cannot be understated. These machines play a pivotal role in transforming digital designs into tangible fabrics, revolutionizing the fashion industry and enabling designers to bring their visions to life.,The process begins with the design phase where intricate patterns and designs are created using software. Once these designs are finalized, they are sent to the transfer machine for execution. The machine uses specialized tools to precisely cut out the desired pattern, ensuring that each stitch is aligned perfectly.,Once the pattern is cut, it is transferred onto the fabric using a heat source. This process involves heating the material until it becomes pliable, allowing the pattern to adhere to the surface. The machine then moves in precise strokes, creating a seamless connection between the two materials.,The result is a piece of clothing that is not only visually stunning but also functional. The transfer machine's ability to create high-quality designs at a faster rate than traditional methods makes it an essential tool for designers looking to stay ahead of the competition.,In conclusion, the power of transfer machines lies in their ability to transform digital designs into physical products. With their precision and efficiency, these machines are changing the way we produce clothing and other textiles, making it easier for designers to bring their visions to life.

In the realm of textile manufacturing, there is a machine that stands out as a game-changer—the textile transfer machine. This revolutionary tool has revolutionized the way we approach printing and decorating fabrics, offering unparalleled precision and efficiency. In this article, we will delve into the intricacies of textile transfer machines, their applications, and how they have transformed the industry.

At its core, a textile transfer machine is a sophisticated piece of machinery designed to apply patterns or designs onto fabrics using heat and pressure. Unlike traditional methods such as screen printing or embroidery, transfer machines allow for the precise placement of intricate designs on a wide range of substrates, including cotton, polyester, and even non-woven materials.

The process begins with the creation of the design. This can be done manually by hand or through computer-aided design software. Once the design is ready, it is printed onto a transfer paper or film using a high-resolution printer. The next step is to apply the design to the fabric using the transfer machine.

One of the key features of a textile transfer machine is its ability to handle multiple colors and patterns simultaneously. This is achieved through the use of specialized rollers and blades that ensure even coverage and consistent results. Additionally, some machines offer additional features such as automatic cutting and trimming, allowing operators to save time and effort while still achieving high-quality results.

The applications of textile transfer machines are vast and varied. One example is the manufacture of fashion accessories, where intricate designs can be applied to fabrics using these machines. Another area where textile transfer machines are used extensively is in the automotive industry, where they are used to apply interior graphics and decals to vehicles.

To illustrate the effectiveness of textile transfer machines, let's take a look at an example from the fashion industry. A designer was tasked with creating a new collection of clothing for a popular brand. The challenge was to create unique and eye-catching designs that would appeal to both men and women. Using a textile transfer machine, the designer was able to apply intricate floral patterns onto a variety of fabrics, including denim, linen, and silk. The resulting garments were not only visually stunning but also highly functional, making them a hit among customers.

Another example comes from the automotive industry. A car manufacturer needed to update its interior graphics for a new model. With traditional methods being time-consuming and costly, the company turned to a textile transfer machine. By applying high-definition images onto the fabric using the machine, the manufacturer was able to create a seamless and cohesive look across all interior components. This not only improved the aesthetic appeal of the vehicle but also made it more durable and resistant to wear and tear.

In conclusion, textile transfer machines are a powerful tool that has transformed the way we approach textile printing and decorating. From fashion accessories to automotive interiors, these machines offer unparalleled precision and efficiency, enabling designers and manufacturers alike to create stunning results that stand out in a crowded marketplace. As technology continues to advance, we can expect textile transfer machines to become even more sophisticated and versatile, opening up even more possibilities for the textile industry.

纺织品转印机简介

纺织品转印机是一种先进的设备,主要用于将图案或文字转移到纺织品上,它通过特殊的印刷技术,将图案或文字转移到纺织品材料上,从而实现高质量、高效率的印刷效果,在当今快节奏的纺织行业中,转印机已经成为提高产品质量和效率的关键设备。

转印机的工作原理

转印机的工作原理主要基于静电吸附和印刷油墨的转移,在转印机中,通过高压静电场将油墨吸附到纺织品表面,然后通过印刷滚筒将图案或文字按照设计要求转移到纺织品上,在这个过程中,转印机的操作参数如电压、压力、速度等都会影响印刷效果和质量。

转印机的应用案例

时尚纺织品转印

近年来,纺织品转印机在时尚纺织品领域得到了广泛应用,设计师可以使用转印机将图案或文字印刷到丝绸、棉布等纺织品上,制作出各种时尚服装和家居用品,这种转印技术不仅可以提高纺织品的外观质量,还可以提高产品的附加值和市场竞争力。

环保纺织品转印

随着环保意识的不断提高,纺织品转印机也在环保领域得到了广泛应用,一些环保纺织品制造商可以使用转印机将环保标志、图案等环保元素印刷到纺织品上,提高产品的环保性能和品牌形象,转印机还可以用于制作各种可降解、可回收的纺织品,符合当前绿色环保的趋势。

转印机的技术特点

转印机的技术特点主要包括高精度印刷、高效率、高稳定性等,高精度印刷是转印机的重要特点之一,可以保证印刷图案或文字的精度和质量;高效率则是转印机的重要优势之一,可以大大提高生产效率和降低成本;高稳定性则是转印机的重要保证之一,可以保证印刷过程的稳定性和可靠性。

转印机的操作与维护

在使用转印机时,需要注意一些操作与维护事项,需要选择合适的印刷材料和图案设计,以确保印刷效果和质量,需要控制好操作参数,如电压、压力、速度等,以获得高质量的印刷效果,还需要定期对转印机进行维护和保养,以确保其正常运转和延长使用寿命。

转印机的未来发展趋势

随着科技的不断进步和纺织行业的不断发展,转印机将会继续得到广泛应用和发展,转印机将会更加智能化、自动化和高效化,提高生产效率和产品质量,转印机还将更加注重环保和可持续性,制作出更加环保、可持续的纺织品。

Articles related to the knowledge points of this article:

Easty Textiles:The Global Fabric of Modern Living

The Science Behind Colorful Textile Dyes

The Future of Textiles:An Overview of Silverdale Textiles

The Dynamics of Sustainable Fashion:An Exploration into Lichuang Textile