How to Start a Textile Factory

Starting a textile factory is an exciting venture, but it also requires careful planning and execution. Here are some key steps to follow:,1. Conduct market research: Before starting a textile factory, it's important to understand the market demand for your product. This will help you determine the size of your factory, the types of products you will produce, and the target customers.,2. Choose a location: A good location is essential for a successful textile factory. Look for areas with access to raw materials, skilled labor, and markets for your products.,3. Develop a business plan: A well-written business plan will help you define your goals, strategies, and financial projections. It's also important to consider legal and regulatory requirements for operating a factory.,4. Obtain financing: Starting a textile factory can be expensive, so it's important to secure funding from investors or lenders. Consider obtaining loans or grants from government agencies or private organizations that support small businesses.,5. Build a team: A successful textile factory requires a skilled team of employees who can handle various tasks, including production, quality control, and marketing.,6. Implement quality control measures: To ensure the quality of your products, implement strict quality control measures throughout the manufacturing process.,7. Expand and innovate: As your business grows, consider expanding into new markets or introducing new products to stay competitive in the industry.

Introduction: Textile manufacturing is a crucial industry that provides us with clothing, household textiles, and other essential products. If you're interested in starting your own textile factory, here are some steps to follow. In this guide, we will also provide an example of how a successful textile factory was established.

Step 1: Research and Planning Before starting the process, it's important to conduct thorough research on the market demand for textile products. You should also create a detailed plan outlining the goals of the business, including the types of products you will produce, target customers, and expected sales volume.

Table 1: Market Research and Business Plan | Product Type | Market Demand | Target Customers | Sales Volume Estimate | |------------|--------------|-----------------|---------------------| | Clothing | High | Middle-Class Consumers | $20 million per year | | Home Textiles | Medium | Low-Income Households | $5 million per year | | Accessories | Low | Young Professionals | $1 million per year |

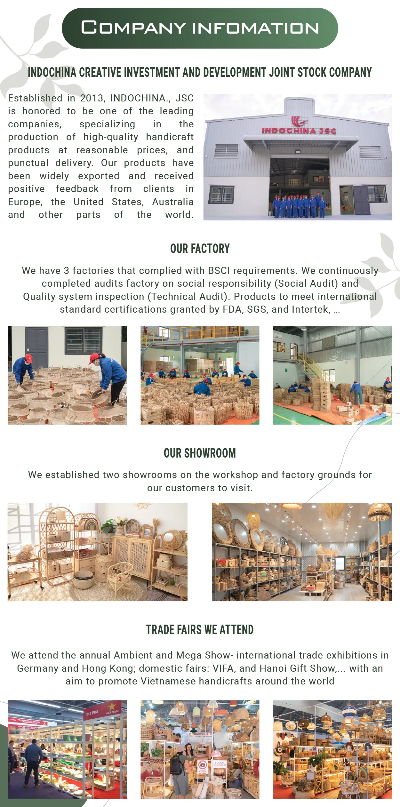

Step 2: Choosing the Right Location The location of your factory can significantly impact your operations. It's important to choose a place that has access to raw materials, skilled labor, and transportation networks. A good example of a successful textile factory is the "Sinopec" in China. They have established factories in various regions to serve their diverse customer base.

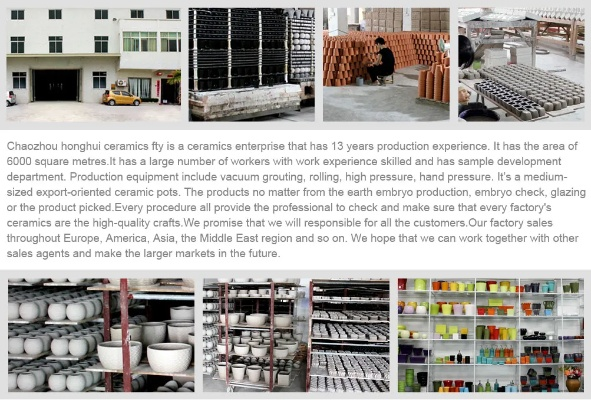

Step 3: Setting Up the Production Process Once you have chosen your location, you need to set up the production process. This includes choosing the appropriate machinery, setting up the production line, and training the staff. For example, a typical textile factory might have a machine that produces fabric from cotton or polyester. The production line would then be responsible for cutting, sewing, and finishing the fabric into finished products.

Step 4: Establishing Supply Chain A successful textile factory must have a robust supply chain to ensure timely delivery of raw materials and finished products. This involves partnering with suppliers, establishing relationships with distributors, and developing logistics systems to ensure efficient transportation and storage.

Step 5: Marketing and Sales Once your product is ready, you need to market and sell it. This involves creating brand awareness, developing marketing strategies, and establishing distribution channels. A successful example of a textile company is the "Zara" in Spain. They have developed a strong brand identity and a well-established marketing strategy to attract customers.

Conclusion: Starting a textile factory requires careful planning, research, and execution. By following these steps, you can establish a successful business that meets the needs of your customers while providing a quality product. Remember to always stay updated with industry trends and customer preferences to ensure long-term success.

大家好,今天我们将探讨如何开设一家纺织厂,开设纺织厂是一个充满机遇和挑战的过程,需要综合考虑市场环境、技术设备、生产流程等多个方面,下面我们将从多个角度详细介绍开设纺织厂的步骤和注意事项。

市场调研与选址

在开始纺织厂建设之前,首先需要进行深入的市场调研,了解当地纺织行业的现状和发展趋势,还需要考虑工厂的选址问题,选择交通便利、劳动力成本低、原料供应充足的区域,还可以参考一些成功的纺织厂案例,了解其他工厂的成功经验和不足之处。

技术设备选择与采购

在选择技术设备和采购原材料时,需要考虑以下几个方面:

- 设备选择:根据生产需求和工艺要求,选择适合的纺织设备,如织布机、染整设备等,还需要考虑设备的耐用性和稳定性。

- 采购流程:可以通过招标、询价等方式进行采购,确保采购到性价比高的设备和技术,在采购过程中,还需要关注设备的环保性能和安全性。

生产流程设计与优化

在生产流程方面,需要考虑以下几个方面:

- 原料采购与检验:确保原料的质量和数量符合生产要求。

- 生产流程设计:根据生产工艺和设备情况,设计合理的生产流程,确保生产效率和质量。

- 员工培训与管理:对员工进行培训,提高员工技能水平和生产效率,还需要建立完善的管理制度,确保生产过程的规范性和安全性。

案例分析

下面我们通过一个成功的纺织厂案例来进一步说明如何开设纺织厂,某地区有一个知名的纺织厂,以其高品质的产品和良好的口碑赢得了市场的认可,该纺织厂在技术设备选择和采购方面非常注重质量和性价比,同时注重生产流程的优化和员工的培训与管理,该工厂的成功经验包括以下几点:

- 市场调研充分:该工厂在选址时充分考虑了当地市场需求和竞争情况,确保工厂能够满足市场需求。

- 设备选择合理:该工厂选择了先进的纺织设备和技术,确保生产效率和产品质量。

- 生产流程优化:该工厂注重生产流程的优化和改进,不断提高生产效率和产品质量,还建立了完善的管理制度,确保生产过程的规范性和安全性。

注意事项

在开设纺织厂的过程中,还需要注意以下几个方面:

- 政策法规:了解当地政策法规,确保工厂符合相关法律法规要求。

- 环保安全:纺织行业是一个环保行业,需要注重环保和安全方面的要求。

- 成本控制:在成本控制方面需要合理规划生产成本和人力成本,确保工厂盈利水平。

- 持续改进:纺织行业是一个不断发展的行业,需要持续改进和提高生产效率和质量。

开设纺织厂需要综合考虑多个方面,包括市场调研、技术设备选择、生产流程设计、成本控制等,还需要注重环保和安全方面的要求,通过深入的市场调研和案例分析,可以更好地了解当地市场需求和竞争情况,为工厂的建设和发展提供参考,还需要注重持续改进和提高生产效率和质量,确保工厂能够持续盈利和发展。

Articles related to the knowledge points of this article:

The Story of Suzhous Loom and Yarn Manufacturing

The Journey of Innovation at Jining JiaXiang Textile Factory