Transforming the Textile World:An In-Depth Look at Minhe Textile Factory

Minhe Textile Factory, a prominent manufacturer in the textile industry, has undergone a significant transformation over the years. This transformation was driven by a combination of factors including technological advancements, market demands, and a commitment to sustainability and quality.,The factory's production process has been meticulously designed to optimize efficiency and minimize waste. This is achieved through the use of state-of-the-art machinery and equipment, which are constantly updated and improved to meet changing market needs.,In addition to its production capabilities, Minhe Textile Factory also places a strong emphasis on innovation and research and development. The factory collaborates with leading universities and research institutions to develop new technologies and products that can enhance the overall performance and quality of its products.,Overall, Minhe Textile Factory's transformative journey reflects a commitment to excellence, sustainability, and customer satisfaction. As the industry continues to evolve, it remains a beacon of innovation and leadership in the textile sector.

Introduction: In the tapestry of global trade, China stands as a beacon of innovation and manufacturing excellence. Among its numerous enterprises, Minhe Textile Factory (MTF) stands out as an exemplar of industrial progress in textile manufacturing. This factory is more than just a producer of fabrics; it's a testament to China's commitment to sustainable growth and quality-driven production. With its meticulous craftsmanship and innovative strategies, MTF is poised to shape the future of textile industry globally.

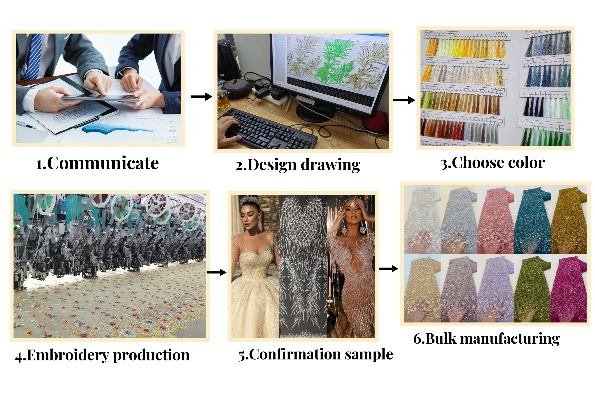

Production Process: The manufacturing process at MTF involves several key steps to produce high-quality textiles. The first step involves selecting raw materials such as cotton, synthetic fibers, or blends that meet specific requirements for their end use. These materials are then processed through various stages including cleaning, spinning, and carding, which prepares them for the weaving or knitting stage.

Weaving and Knitting: Once the raw materials are prepared, they are woven or knitted according to the desired design and pattern. The weaving process involves laying two sets of threads on a flat surface and interweaving them in a crisscross fashion to create a cloth. On the other hand, knitting involves interlocking loops of yarn, creating a textured fabric. Both methods have their unique advantages depending on the desired outcome.

Quality Control: Quality control is crucial at MTF. Each stage of the production process is closely monitored to ensure uniformity in quality and conformance to standards. This includes testing for defects such as thread breaks, uneven weaving patterns, or loose stitching. Any issues are promptly addressed to prevent defective products from reaching customers.

Technology Adoption: To stay ahead in the competitive textile industry, MTF has embraced modern technologies like automated machines and robotic processes. These tools not only increase efficiency but also enhance product quality. They help in reducing human error, increasing production rates, and maintaining consistency across different production lines.

Market Expansion: With an emphasis on quality and innovation, MTF has expanded its market beyond traditional markets to include emerging ones like Asia and Africa. By offering a wide variety of fabrics and designs, MTF has catered to the needs of diverse customer segments worldwide.

Case Study: Take, for example, the case of a client in India who was looking for high-quality fabrics for their clothing line. MTF's team worked closely with the client to understand their requirements, including color options, material type, and brand image. Based on these inputs, MTF developed a custom blend of cotton and polyester that met all the specifications and exceeded the client’s expectations. This successful collaboration showcases how MTF can adapt to customer needs while adhering to strict quality standards.

Conclusion: Minhe Textile Factory (MTF) stands as a beacon of excellence in the textile industry. Its commitment to sustainability, quality control, and technology adoption has made it a leader in producing high-end, durable, and stylish textiles. With its innovative approach to market expansion and customer-centric approach, MTF is positioned to continue shaping the future of textile industry globally. As we look forward, we can expect more stories like this one from MTF, showcasing its continued success and influence in the world of textile manufacturing.

背景介绍

民合纺织厂是一个专注于纺织生产的工厂,以其精湛的工艺和优质的产品赢得了广大客户的信赖,该厂在当地纺织行业中有着举足轻重的地位,其生产的产品不仅满足了市场需求,还出口到国际市场。

民合纺织厂的发展历程

- 创立初期:民合纺织厂在当地政府的支持下,开始了艰苦创业之路。

- 技术创新:该厂不断引进先进技术,提高生产效率和质量。

- 规模扩张:随着生产规模的扩大,工厂开始拓展国际市场,出口产品遍布全球。

民合纺织厂的主要产品与服务

主要产品:纯棉、涤纶、羊毛等多种纺织材料。

服务:为客户提供定制化生产服务,满足不同客户的需求。

民合纺织厂的运营模式与特点

运营模式:采用现代化管理模式,注重环保、节能、高效的生产方式。

特点:注重产品质量和客户满意度,注重员工培训和发展。

民合纺织厂的案例分析

环保生产案例

近年来,民合纺织厂积极响应环保政策,采用环保生产方式,工厂配备了先进的环保设备和技术,严格控制生产过程中的污染排放,该厂还注重员工环保意识的培训,鼓励员工参与环保活动,提高员工的环保意识,通过这种方式,民合纺织厂不仅提高了生产效率和质量,还为当地环境保护做出了贡献。

技术创新案例

该厂不断引进先进技术,提高生产效率和质量,该厂采用智能生产线技术,提高了生产自动化程度和产品质量稳定性,该厂还注重研发新产品和新工艺,不断拓展产品的种类和功能,这些创新举措不仅提高了工厂的生产能力,还为当地经济发展注入了新的活力。

民合纺织厂的未来展望

未来展望:该厂将继续秉承“以人为本、质量第一”的经营理念,注重技术创新和环保生产,提高生产效率和产品质量,该厂还将拓展国际市场,提高品牌知名度和竞争力,该厂还将加强员工培训和发展,提高员工的综合素质和创新能力。

民合纺织厂是一个充满活力和潜力的企业,其发展历程和未来展望都充满了希望和机遇,该厂将继续秉承“以人为本、质量第一”的经营理念,不断提高生产效率和产品质量,为当地经济发展做出更大的贡献,该厂还将积极响应环保政策,为保护环境、实现可持续发展做出更大的努力。

Articles related to the knowledge points of this article:

The Story of Textile Mills Line Bars

The Global Challenges and Opportunities Faced by Textile Factories

The Dynamics of the Huahai Textile Factory:A Tale of Success and Innovation