The Fabric of Disaster:A Tale of Textile Mills and Potatoes

: A Tale of Textile Mills and Potatoes,In the heart of a rural community lies a textile mill, where threads weave together the lives of those who labor within its walls. The mill is a symbol of progress, a testament to human ingenuity and determination. However, beneath the surface lies a darker side—the exploitation of workers by the mill's owners.,The workers are forced to work long hours without compensation, often sacrificing their health for the sake of the mill's profitability. They live in deplorable conditions, with little food or access to healthcare. The only hope they have is the promise of a better life after the mill closes, but that remains a distant dream.,As the mill continues to operate, the workers' plight grows more pressing. Their struggles become a thorn in the community's side, drawing attention to the injustices they face. It becomes clear that change must come not just for the workers, but for all those who have been left behind.,In this tale of textile mills and potatoes, we see the consequences of greed and neglect on both individuals and communities. It is a story of resilience and hope, of the power of collective action to bring about change.

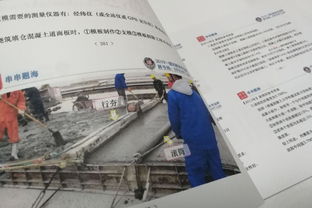

Introduction: In the world of textile production, disasters can occur in seemingly unsuspecting corners. One such incident occurred recently at a textile factory in China, where workers were left to fend for themselves after a massive explosion destroyed their facility. This article explores the complexities of industrial accidents, highlighting the role of human error, technological failure, and environmental factors in creating these tragedies.

Table 1: Common Causes of Industrial Accidents

| Category | Explanation |

|---|---|

| Human Error | Mistakes made by workers, such as improper handling of hazardous materials or equipment malfunctions |

| Technological Failure | Machinery breakdowns, electrical issues, or other technical glitches that result in accidents |

| Environmental Factors | Natural disasters like floods, earthquakes, or strong winds that cause structural damage |

| Lack of Training | Insufficient training for workers on how to handle dangerous situations |

| Lack of Oversight | Inadequate supervision or monitoring systems that fail to detect potential hazards |

Case Study: The textile mill in question was a major producer of garments and accessories for the Chinese market. The factory had been in operation for over a decade and had a reputation for high-quality products. However, recent years had seen a decline in demand due to economic challenges and competition from foreign brands.

On a sunny Saturday morning, workers were busy with their tasks when an unexpected explosion rocked the factory. The blast was so powerful that it blew out windows and shook the building's foundation. Rescue teams rushed to the scene, but they found no survivors. The investigation revealed that the explosion was caused by a faulty piece of machinery that had been neglected for years. The machine had been designed to be safe but had not been properly maintained, leading to its failure during normal use.

The tragedy highlighted the importance of regular maintenance and inspections for industrial equipment. It also underscored the need for better training programs for workers to ensure they understand the risks associated with their jobs.

Conclusion: The textile mill explosion serves as a stark reminder of the dangers lurking within our industrial landscape. While technological advancements have made manufacturing processes more efficient and cost-effective, they have also created new challenges that must be addressed. By understanding the root causes of accidents and implementing preventive measures, we can minimize the risk of similar tragedies occurring in the future.

Table 2: Prevention Strategies for Industrial Accidents

| Strategy | Details |

|---|---|

| Regular Maintenance | Ensure that all machinery is regularly inspected and maintained to detect and fix any potential problems before they become major issues |

| Worker Training | Train employees on proper safety procedures and emergency response protocols |

| Proper Design | Ensure that all equipment is designed to withstand the stresses of heavy use without causing catastrophic failure |

| Monitoring Systems | Install advanced monitoring technologies to detect early warning signs of potential hazards |

| Regulatory Compliance | Adhere to strict safety regulations and guidelines to ensure compliance with industry standards |

By adopting these strategies, we can create a safer work environment for ourselves and those who labor within our factories and mills. Let us remember the lessons of the textile mill explosion and strive towards a future where industrial accidents are a thing of the past.

纺织厂内部,炸土豆的热闹场景

场景人物:工人、厨师、老板等

工人(英文):Worker A, Worker B, Chef X

厨师(英文):Chef Y

老板(英文):Boss

开场白:

老板(兴奋地):各位,今天我们要聊聊纺织厂里的炸土豆盛宴!大家有没有期待已久呢?

工人A(兴奋地):当然有啦!我一直听说纺织厂里的炸土豆特别美味,今天终于可以品尝了!

厨师Y(热情地):没错,今天我们特地为炸土豆准备了丰富的配料和独特的烹饪技巧,炸土豆不仅美味可口,还寓意着团结和协作的精神。

案例说明:

食材准备

表格1:食材清单

| 食材种类 | 用量 | 描述 |

|---|---|---|

| 土豆 | 若干 | 新鲜、饱满、口感丰富 |

| 调料 | 多种口味 | 包括辣椒粉、孜然粉、盐等 |

| 炸油 | 高温油 | 提供炸制所需的油脂条件 |

| 面糊 | 面糊材料 | 包括面粉、鸡蛋等,用于包裹土豆片 |

烹饪过程

场景描述:纺织厂内部厨房,厨师正在忙碌地准备炸土豆的烹饪过程。

厨师X(详细地):我们将土豆清洗干净,然后切成薄片备用,我们将面糊调制好,让每一片土豆都能均匀裹上面糊,我们开始炸制,使用高温油进行炸制,在炸制过程中,我们会加入各种调料,让炸土豆的味道更加丰富,我们还会撒上一些辣椒粉和孜然粉,增加炸土豆的香味和口感。

炸制过程案例说明

成功案例展示

- 准备工作阶段:厨师在准备炸油时,确保油温适宜且无杂质,他先将适量的炸油倒入锅中,然后进行预热,这样做的目的是为了确保炸制过程顺利进行。

- 炸制阶段:在厨师的精心操作下,他将裹好面糊的土豆片放入锅中进行炸制,随着油温的升高,土豆片逐渐变得金黄酥脆,在炸制过程中,厨师不断调整火候和时间,确保每一片土豆都能均匀受热,他还根据个人口味加入了一些辣椒粉和孜然粉,让炸土豆的味道更加丰富多样,经过一番精心炸制,一盘盘香气扑鼻的炸土豆就完成了。

- 出锅装盘:厨师将炸好的土豆装盘上桌,吸引了众多工人的目光,大家纷纷表示期待已久,迫不及待想要品尝这美味的炸土豆,在品尝过程中,大家纷纷表示赞不绝口,对这道菜赞不绝口。

现场感受与互动交流

工人A(兴奋地):哇!这炸土豆真是太好吃了!每一口都让人回味无穷!大家快来尝尝吧!

厨师Y(热情地):好的,大家可以来试试我们的炸土豆!我们还会继续努力为大家带来更多美味的佳肴!

老板(满意地点头):今天的炸土豆盛宴真是让人难以忘怀!希望大家能够继续支持我们的纺织厂!

Articles related to the knowledge points of this article:

The Story of Huatian Textile Factory