The Art of Textile Styling with Stiffening Agents

The Art of Textile Styling with Stiffening Agents,Textile styling is an art that involves the use of stiffening agents to enhance the texture and appearance of fabrics. These agents are used to increase the strength and durability of textiles, making them more resistant to wear and tear. In this article, we will explore the different types of stiffening agents used in textile styling and their applications.,One of the most common types of stiffening agents used in textile styling is polyurethane. Polyurethane is a synthetic material that is used to create a smooth, glossy finish on fabrics. It is commonly used in garments such as shirts, blouses, and dresses. Polyurethane provides a high level of flexibility and resilience, making it ideal for use in sportswear and outdoor clothing.,Another popular stiffening agent used in textile styling is silicone. Silicone is a non-toxic, water-resistant material that is widely used in industrial applications. It is also used in textile styling to create a matte finish on fabrics. Silicone provides excellent resistance to scratches and stains, making it ideal for use in high-traffic areas such as kitchens and bathrooms.,In conclusion, textile styling with stiffening agents is an important aspect of fashion design. The use of these agents not only enhances the appearance of fabrics but also improves their functionality and durability. By understanding the different types of stiffening agents available and their applications, designers can create unique and stylish garments that meet the needs of their customers.

Introduction: In the world of textiles, every fabric is a story waiting to be told. Whether it's the softness and comfort of a cozy sweater or the sharpness and texture of a tailored suit, the finishing touches can make all the difference. One such finishing technique that has gained significant traction in recent years is the use of stiffening agents in textile finishing. These agents add rigidity and structure to fabrics, enhancing their appearance and performance. In this article, we will explore the various types of stiffening agents, their applications, benefits, and some case studies to illustrate their effectiveness.

Types of Stiffening Agents:

-

Acrylic Stiffeners: These are synthetic polymers that impart stiffness to fabrics by creating micro-cracks or wrinkles in the fibers. They are commonly used in apparel and upholstery fabrics.

-

Polyurethane Stiffeners: These are a type of acrylic stiffeners that undergo chemical reactions during curing, resulting in a more durable and flexible finish. They are widely used in carpets, upholstery, and other textiles.

-

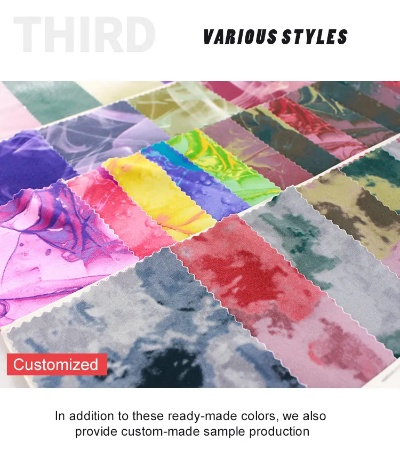

Silk Stiffeners: These are natural products derived from silkworm cocoons that impart a slight stiffness to the fabric. They are often used in luxury textiles like cashmere and silk blends.

-

Natural Stiffeners: These include plant-based materials like wood pulp or cellulose that impart stiffness through physical contact with the fabric. They are gaining popularity due to their eco-friendly nature.

Applications: Stiffening agents are used in a variety of applications across different industries. Here are a few examples:

-

Apparel: Stiffening agents can enhance the drape and smoothness of knitwear and woven fabrics, making them feel more luxurious. For instance, acrylic stiffeners can be added to denim jeans to give them a stronger, more structured look.

-

Upholstery: Polyurethane stiffeners are commonly used in upholstery fabrics to create a firm, durable finish. This is particularly important for high-traffic areas like chairs and sofas, where durability is key.

-

Carpets: Silk stiffeners add a subtle stiffness to carpets, enhancing their appearance and reducing wear and tear over time. This is particularly useful for high-end carpets that require a luxurious finish.

-

Luxury Textiles: Natural stiffeners like wood pulp or cellulose are increasingly being used in luxury textiles like cashmere and silk blends. These materials impart a unique texture and visual appeal that sets these fabrics apart from mass-produced options.

Benefits: The use of stiffening agents offers several benefits to both manufacturers and consumers:

-

Durability: Stiffening agents impart a layer of strength to fabrics, making them resistant to wear and tear. This extends the lifespan of garments, furniture, and other textiles, reducing the need for frequent replacement.

-

Enhanced Appearance: Stiffening agents can alter the appearance of fabrics by adding a crisp, structured feel. This can make fabrics appear more polished and professional, making them suitable for high-end applications like upholstery and clothing.

-

Eco-Friendly: Natural stiffeners like wood pulp or cellulose are biodegradable and environmentally friendly alternatives to traditional acrylic and polyurethane stiffeners. This makes them an attractive option for consumers looking for sustainable products.

Case Study: Consider the case of a luxury hotel chain that wanted to upgrade its guest rooms with a more sophisticated finish. They decided to incorporate polyurethane stiffeners into the bedding fabrics to create a more durable and structured look. The result was a hotel that not only looked more luxurious but also felt softer and more comfortable to sleep on. Consumers reported increased satisfaction with their stay, leading to increased bookings and positive word-of-mouth.

Conclusion: Stiffening agents offer a versatile solution for enhancing the appearance and performance of textiles. From apparel and upholstery to carpets and luxury textiles, these agents have become essential tools in the textile industry. By understanding the different types of stiffening agents available and their applications, manufacturers can choose the right product for their specific needs. As demand for eco-friendly and sustainable products continues to grow, natural stiffeners like wood pulp and cellulose are poised to play a larger role in the textile industry.

纺织品后整理硬挺剂概述

纺织品后整理硬挺剂是一种用于提升纺织品硬挺度和定型效果的化学助剂,它们通过一系列复杂的工艺过程,在纺织品表面形成坚固的纤维结构,赋予其特定的硬挺度和定型效果,在纺织行业中,硬挺剂的应用越来越广泛,尤其在高端服装、家居装饰等领域。

硬挺剂的主要作用与功能

硬挺剂的主要作用是增强纺织品的硬挺度和定型效果,它可以增加纤维之间的结合力,提高织物的抗皱性,使纺织品在穿着过程中不易变形,硬挺剂还可以改善织物的手感、外观和舒适度。

硬挺剂的主要类型与特点

目前市场上常见的硬挺剂主要包括聚合物纤维增强剂、硅烷偶联剂等,这些硬挺剂具有以下特点:

- 聚合物纤维增强剂:通过添加聚合物纤维增强剂,可以显著提高纺织品的硬挺度和定型效果,这些聚合物纤维具有高强度、高模量等特点,能够有效地提高织物的抗皱性和定型效果。

- 硅烷偶联剂:硅烷偶联剂是一种特殊的化学助剂,能够与纤维表面进行化学反应,形成牢固的化学键,从而提高纤维之间的结合力,硅烷偶联剂还可以改善织物的手感、外观和舒适度。

案例分析:纺织品后整理硬挺剂的实践应用

以某知名品牌的一款高端服装面料为例,该面料采用了先进的纺织品后整理硬挺剂技术,实现了出色的硬挺度和定型效果。

该面料在生产过程中采用了先进的硬挺剂配方,通过一系列复杂的工艺过程,在面料表面形成了坚固的纤维结构,使用硬挺剂后,该面料具有较高的抗皱性和定型效果,使得服装在穿着过程中不易变形,该面料的手感柔软舒适,外观美观大方,深受消费者喜爱。

硬挺剂生产工艺与设备介绍

硬挺剂的生产工艺和设备主要包括以下几个环节:

- 原料准备:选择高质量的聚合物纤维和化学助剂作为原料。

- 混合与分散:将原料按照一定比例混合均匀,形成均匀的助剂溶液。

- 反应与固化:将助剂溶液通过特定的工艺过程进行反应和固化,形成坚固的纤维结构。

- 后续处理:对固化后的纺织品进行后续处理,如烘干、定型等。

硬挺剂的应用前景与市场趋势

随着人们对纺织品品质和外观要求的不断提高,硬挺剂的应用前景越来越广阔,随着技术的不断进步和产品质量的不断提高,硬挺剂将在纺织行业中发挥更加重要的作用,随着消费者对纺织品品质和舒适度的要求不断提高,硬挺剂的市场需求也将不断增长。

纺织品后整理硬挺剂是一种重要的纺织助剂,能够显著提高纺织品的硬挺度和定型效果,在纺织行业中,硬挺剂的应用越来越广泛,具有广阔的市场前景,随着技术的不断进步和消费者对纺织品品质和舒适度的要求不断提高,硬挺剂的应用将会更加广泛和深入。

Articles related to the knowledge points of this article:

The Magic of Wave-Inspired Textiles

The Navigating Challenges of Applying for Jobs at Hangzhou Jiexi Ju Textiles

Exploring the World of Jilin Textiles:An Unmissable Journey

The Story of Scentastic Textiles 盛祥纺织品的魅力与传奇

The Impact of Textile Breaking Strength on Quality and Usage