Navigating the Textile Industry:A Comprehensive Guide to the Processing Flow

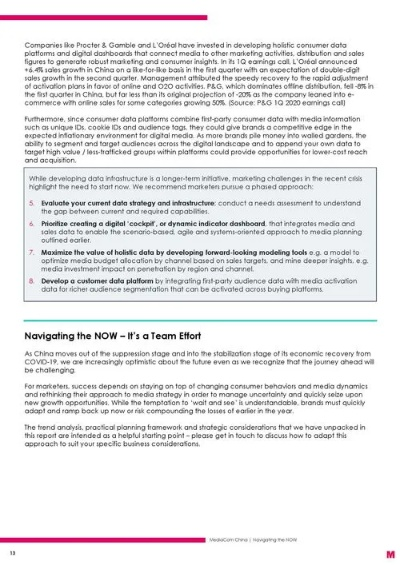

: Navigating the Textile Industry: A Comprehensive Guide to the Processing Flow,Abstract:,The textile industry is a complex and dynamic sector, characterized by its multifaceted processes that involve raw material procurement, design, manufacture, and final product distribution. This comprehensive guide aims to provide readers with an in-depth understanding of the textile processing flow, from raw materials to finished products. The guide covers topics such as the textile industry's economic significance, the various stages involved in the manufacturing process, the importance of quality control, and the impact of technology on the industry. By providing insights into these key areas, the guide aims to empower readers with the knowledge necessary to navigate the textile industry effectively.

Introduction: In the textile industry, every step of the process is crucial in ensuring quality, efficiency, and sustainability. From raw materials to finished products, there's a complex chain of operations that must be executed flawlessly. This guide will walk you through the key stages of the textile processing flow, highlighting the importance of each step and providing insights into how they contribute to the final product.

Raw Materials: The foundation of any textile production lies in the raw materials. These include cotton, polyester, wool, and other natural fibers as well as synthetic ones like nylon and spandex. Each material has its unique properties that affect the final product's texture, durability, and appearance. For example, cotton is softer and more breathable than synthetic materials, while polyester is strong and durable but prone to pilling.

Preparation: Once the raw materials are gathered, they undergo various processes to prepare them for the next stage. This includes carding, which involves combing the fibers to remove impurities and improve their uniformity. Then, the materials are spun into yarns, which are thin strands of fiber that can be woven or knitted into fabric.

Weaving/Knitting: The next step in the process is weaving or knitting. Here, the yarns are interlaced to form a fabric. Weaving involves using a loom to create a continuous strip of fabric, while knitting involves creating a pattern by pulling individual threads through a circular needle. Both methods have their advantages depending on the desired outcome, with weaving producing a stronger, more durable fabric and knitting yielding a lighter, more breathable option.

Dyeing: After the fabric is woven or knitted, it undergoes dyeing to give it color. This process involves treating the fabric with chemicals that penetrate the fibers and change their color. The choice of dye depends on the desired shade and level of coverage, and this step is crucial in achieving a consistent and attractive finish.

Finishing: Once the fabric is dyed, it enters the finishing stage. This includes treatments such as steaming, softening, and finishing with waxes or coatings to enhance its performance and appearance. Some finishes also include treatments like flame-retardant agents or antimicrobial agents to make the fabric more resistant to wear and tear.

Spinning: For those looking to produce yarn, spinning is the next step. Yarn is made from long strands of fiber that are twisted together to form a continuous thread. This process is essential for creating soft, luxurious fabrics like silk or cashmere.

Weaving/Knitting: As mentioned earlier, the next step in the process is weaving or knitting. This involves interlacing the yarns to create a fabric. Weaving produces a stronger, more durable fabric, while knitting yields a lighter, more breathable option.

Dyeing: Following weaving or knitting, the fabric goes through dyeing to add color. This step is crucial in achieving a consistent and attractive finish.

Finishing: Finally, the fabric undergoes finishing to enhance its performance and appearance. This includes treatments like steaming, softening, and finishing with waxes or coatings. Some finishes also include treatments like flame-retardant agents or antimicrobial agents to make the fabric more resistant to wear and tear.

Conclusion: The textile industry is a complex and multifaceted one, with each step playing an integral role in the final product's quality, functionality, and appeal. By understanding the process from raw materials to finished goods, you can gain a deeper appreciation for the craftsmanship involved and appreciate the value that goes into creating textiles that meet our needs and desires.

纺织厂作为制造业的重要组成部分,承担着生产各种纺织品的重要任务,其加工流程涉及多个环节,确保产品从原材料到最终成品的质量和效率,下面将详细介绍纺织厂的加工流程及其关键环节。

纺织厂加工流程

原料收集与检验

原料从供应商处采购后,首先需要进行严格的检验,确保原料的质量符合标准,这一环节包括对原料的外观、尺寸、成分等各项指标进行检测,确保原料的纯净度和有效性。

预处理与整理

根据纺织品的种类和工艺要求,对原料进行预处理和整理,这包括对纤维的梳理、混合、拉伸等工序,以优化织物的结构和性能,对纺织品进行必要的清洁和整理,以提高其外观质量和手感。

织造工序

织造工序是纺织厂的核心环节,涉及织布、裁剪、缝制等工序,在织造过程中,根据设计图纸和客户要求,采用先进的织造技术,如平纹、斜纹、提花等,将纤维编织成各种形状和规格的纺织品,根据产品特性和工艺要求,调整织布参数和工艺流程。

染整工序

染整工序包括染色和整理两个环节,在染色过程中,使用各种染料对纺织品进行染色处理,以获得所需的颜色和图案,根据产品特性和客户要求,进行必要的整理,如磨毛、起毛、防皱等处理,以提高产品的外观质量和手感。

成品检验与包装

完成织造和染整工序后,进行成品检验和包装,这一环节包括对成品的质量、尺寸、颜色等进行检测,确保产品符合标准,根据客户需求进行包装设计,确保产品美观、安全、易于运输。

案例说明

以某纺织厂为例,其加工流程如下:

- 原料收集与检验:该纺织厂从供应商处采购高质量的原料,并进行严格的检验,确保原料的质量符合标准。

- 预处理与整理:根据纺织品的种类和工艺要求,对原料进行预处理和整理,该厂采用先进的织造技术,优化织物结构和性能,提高产品的外观质量和手感,对纺织品进行清洁和整理,以满足客户的需求。

- 织造工序:该纺织厂采用先进的织造设备和技术,采用平纹、斜纹等多种织造工艺,生产出各种规格和形状的纺织品,根据产品特性和工艺要求,调整织布参数和工艺流程,以达到最佳的产品性能。

- 染整工序:该纺织厂采用多种染料和技术进行染色处理,以获得所需的颜色和图案,根据客户要求进行磨毛、起毛、防皱等处理,以提高产品的外观质量和手感,该厂还注重环保和可持续性,采用环保染料和技术进行处理。

- 成品检验与包装:该纺织厂对成品进行严格的质量检测和包装设计,确保产品符合标准,注重产品的美观、安全、易于运输等方面,为客户提供优质的产品和服务。

英文表格补充说明

以下为英文表格补充说明纺织厂加工流程的相关信息:

表格1:纺织厂加工流程示例

| 步骤 | 描述 | 设备/技术 | 说明 |

|---|---|---|---|

| 原料收集与检验 | 从供应商处采购高质量原料 | 机械/自动化设备 | 对原料进行外观、尺寸、成分等指标检测 |

| 预处理与整理 | 根据纺织品的种类和工艺要求进行预处理和整理 | 织造设备/整理设备 | 采用先进的织造技术优化织物结构和性能 |

| 织造工序 | 采用平纹、斜纹等多种织造工艺 | 织造设备/染整设备 | 根据设计图纸和客户要求进行织布和染色处理 |

| 染整工序 | 进行染整处理 | 染料/整理设备 | 使用多种染料和技术进行染色处理并满足客户要求 |

| 成品检验与包装 | 进行质量检测和包装设计 | 质量检测设备/包装设备 | 对成品进行质量检测和包装设计以满足客户需求 |

纺织厂的加工流程是一个复杂而精细的过程,需要各个环节紧密配合、协同工作,通过上述介绍和分析,我们可以更好地了解纺织厂的加工流程及其关键环节,在实际操作中,还需要注意环保、安全等方面的要求,确保生产过程的可持续性和质量稳定性。

Articles related to the knowledge points of this article:

Fabricating Quality The Role of 定型工艺 in Textile Production

The Dynamics and Innovations at Dunzhou Spray Water Textile Factory