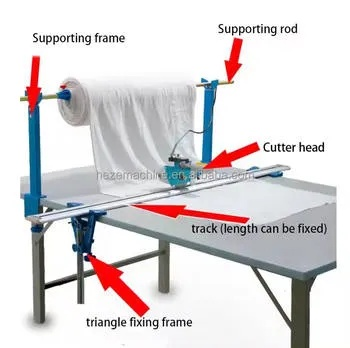

How to Use a Textile Finishing Blade for Application and Maintenance

: Textile Finishing Blade Application and Maintenance,In the textile industry, a finishing blade is an essential tool for achieving precise cuts and smooth edges. Here are some tips on how to use and maintain a textile finishing blade effectively.,Firstly, before using the blade, it is important to clean it thoroughly with warm water and mild soap. This will remove any dirt or debris that may have accumulated on the blade during use.,Next, choose the appropriate cutting method for the fabric being worked with. For example, if working with thicker materials, a rotary cutting motion may be necessary.,When cutting, ensure that the blade is positioned correctly and aligned with the fabric. Use light pressure when cutting to prevent damaging the blade.,After each use, rinse the blade in warm water and dry it thoroughly before storing it away from direct sunlight and moisture. This will help prolong its lifespan and prevent rusting.,In conclusion, by following these simple steps, you can ensure that your textile finishing blade remains in excellent condition for years to come.

Introduction: In the textile industry, finishing blades are essential tools used in the application of various coatings and finishes onto fabric. These blades are designed to precisely cut through the material and facilitate the even distribution of the desired finish. In this guide, we will discuss how to use a textile finishing blade, including its proper installation, usage, and maintenance.

Installation: Before using a finishing blade, it is important to ensure that it is properly installed in the machine. Here is a table summarizing the steps for installing a finishing blade:

| Step | Description |

|---|---|

| 1 | Choose the correct finishing blade size for your machine. |

| 2 | Remove any old blades from the machine. |

| 3 | Clean the cutting area of the blade with a solvent or oil. |

| 4 | Install the new finishing blade into the machine. |

| 5 | Test the blade by running a test cut through the material. |

Usage: Once the blade is installed, it is time to apply the finishing treatment. Here are some tips for using a finishing blade:

| Step | Description |

|---|---|

| 1 | Cut a small sample of the material to test the blade's performance. |

| 2 | Apply the finishing treatment to the sample using the appropriate solvent or oil. |

| 3 | Cut the sample again to check for uniformity in the finish. |

| 4 | If necessary, adjust the blade settings to achieve the desired finish. |

| 5 | Continue applying the finishing treatment to the entire piece of material. |

Maintenance: To ensure that the finishing blade remains effective and lasts longer, proper maintenance is crucial. Here are some tips for maintaining a finishing blade:

| Step | Description |

|---|---|

| 1 | Clean the blade regularly with a solvent or oil to prevent rust and corrosion. |

| 2 | Store the blade in a dry, dust-free environment to prevent damage. |

| 3 | Check the blade for any signs of wear or damage and replace it as needed. |

| 4 | Keep the blade sharp by regularly sharpening it with a grinding wheel or other appropriate tool. |

Case Study: Let's take a look at a real-world example of how to use a textile finishing blade. Suppose you are working on a garment with a delicate satin finish. To achieve this, you would need to use a specialized satin finishing blade that has a fine edge to avoid damaging the delicate fabric. Here's how you can use this blade:

- Cut a small sample of the satin fabric to test the blade's performance.

- Apply the satin finish using a solvent or oil specifically designed for satin fabrics.

- Cut the sample again to check for uniformity in the finish.

- If necessary, adjust the blade settings to achieve the desired finish.

- Continue applying the satin finish to the entire piece of satin fabric.

Conclusion: In conclusion, using a textile finishing blade requires proper installation, careful usage, and regular maintenance. By following these guidelines, you can ensure that your fabric receives a high-quality finish that enhances its aesthetic appeal and durability. Remember to consult the manufacturer's instructions for specific guidance on using your finishing blade.

大家好,今天我们来聊聊纺织品涂布过程中的刮刀使用技巧,在纺织行业中,涂布技术是提高产品质量、提升产品附加值的重要手段,而刮刀作为涂布过程中的关键工具,其正确使用对于提高生产效率和产品质量至关重要,下面我们将详细介绍纺织品涂布刮刀的使用方法和注意事项。

纺织品涂布刮刀的基本结构与功能

基本结构

纺织品涂布刮刀主要由刀片、刀柄和手柄组成,刀片是刮涂的主要工具,具有锋利的刃口和良好的耐磨性,刀柄则用于固定和调节刮刀的角度和力度,手柄则提供了操作时的舒适度和稳定性。

功能介绍

刮涂是纺织品涂布过程中的重要步骤,其主要功能是清除纺织品表面的杂质、涂层、油污等,为后续涂层处理提供良好的基础,正确的刮刀使用可以确保涂层的均匀性和一致性,提高涂布质量。

纺织品涂布刮刀的使用方法

准备工作

在使用纺织品涂布刮刀之前,需要先检查刮刀的状态,确保其锋利、无损伤,需要准备好所需的工具和材料,如涂料、基材等。

使用步骤

(1)涂抹涂料:根据需要涂层的面积和厚度,将适量的涂料均匀涂抹在基材表面,涂抹时要注意涂抹的均匀性和一致性。

(2)调整角度和力度:根据需要处理的表面情况,调整刮刀的角度和力度,角度要适中,力度要适中,避免过大或过小。

(3)开始刮涂:将刮刀紧贴基材表面,开始刮涂,在刮涂过程中要注意控制速度和力度,避免过度用力导致基材损伤。

使用注意事项

(1)在使用过程中要避免刮刀与手部接触,以免划伤手部皮肤,要避免在潮湿或污染的环境中使用刮刀,以免影响涂布效果。

(2)在使用过程中要注意观察基材表面情况,及时调整刮刀的角度和力度,确保涂布效果。

案例说明

下面我们通过一个具体的案例来说明纺织品涂布刮刀的使用方法:

假设某纺织企业使用了一种新型的纺织品涂布刮刀进行生产,该刮刀具有以下特点:采用高强度材料制成,刃口锋利耐用;角度调节范围广,可以根据不同表面情况调整角度和力度;操作简便,易于掌握,在使用该刮刀的过程中,需要注意以下几点:首先进行涂抹涂料前的准备工作,检查刮刀状态;其次根据需要处理的表面情况调整刮刀的角度和力度;最后开始刮涂,控制速度和力度,避免过度用力导致基材损伤,通过该案例可以看出,正确的使用方法可以确保涂布效果的一致性和均匀性,提高生产效率和质量。

总结与建议

纺织品涂布刮刀的使用对于提高生产效率和产品质量至关重要,在使用过程中需要注意以下几点:首先进行准备工作,确保刮刀状态良好;其次根据需要处理的表面情况调整角度和力度;最后注意操作细节,避免过度用力导致基材损伤,建议在使用过程中要注意观察基材表面情况,及时调整刮刀的角度和力度,确保涂布效果,还可以通过不断学习和实践提高自己的技术水平,更好地掌握纺织品涂布刮刀的使用方法。

Articles related to the knowledge points of this article:

Trends in Technological Textiles and Clothing:A Comprehensive Guide

Introduction to the Fabric Ingredient Adhesive

Top Ten Recommendations for Quality Textiles in Shanghai