The Art of Knotting in the Textile Industry

Knotting, a fundamental technique in the textile industry, involves the interlacing of threads to form patterns, textures, and structures. This process is crucial for creating garments, upholstery, and other textile products. The art of knotting involves selecting appropriate materials, understanding the properties of the threads, and developing techniques that result in aesthetically pleasing and functional designs. In this article, we will explore the various types of knots used in the textile industry, their applications, and the skills required to master this craft. We will also discuss the importance of knotting in the textile industry and how it contributes to the overall quality and value of textile products.

In the world of textiles, knotting is not just a simple task but a craft that embodies the essence of precision and artistry. From the meticulous weaving of threads to the intricate tying of knots, every detail contributes to the final product's quality and durability. In this article, we will explore the various techniques used in knotting, their significance in the textile industry, and how they can be applied in practical scenarios.

Knotting is a crucial step in the production process of textiles, as it helps to secure the fibers together and prevent them from unraveling. There are several types of knots used in textiles, including basic single-strand knots, double-strand knots, and triple-strand knots. Each type has its unique characteristics and benefits, depending on the specific requirements of the textile product.

One of the most common knots used in textiles is the basic single-strand knot. This knot is formed by crossing two strands of yarn and then pulling them tight. It is a simple yet effective technique that can be easily mastered by even novice knitters. The basic single-strand knot is commonly used in sweaters, hats, and scarves, where it provides a snug fit and adds texture to the fabric.

Another popular knot is the double-strand knot, which involves crossing two strands of yarn and then twisting them together. This knot creates a more secure hold than the basic single-strand knot and is ideal for garments such as jackets and coats. The double-strand knot also adds a decorative element to the fabric, making it visually appealing.

The triple-strand knot is a more advanced technique that involves crossing three strands of yarn and then twisting them together. This knot provides the strongest hold possible and is commonly used in high-end textile products such as cashmere sweaters and luxury scarves. The triple-strand knot is also known for its durability and longevity, making it an ideal choice for high-quality textiles.

In addition to these basic knots, there are also specialized knots used in different industries. For example, in the fashion industry, there are various patterns and designs created using different knots, such as the French Knot or the Half Knot. These knots add a touch of elegance and sophistication to clothing and accessories, making them stand out from the crowd.

In the healthcare industry, knotting plays a critical role in medical equipment and supplies. For example, in surgical gloves, the knots are carefully designed to ensure a tight grip without causing discomfort or injury to the patient. Similarly, in medical masks, the knots are essential for maintaining airtight seals and preventing contamination.

In the food industry, knotting is also used extensively to package and preserve food products. In particular, the use of rubber bands in packaging materials is a common practice that helps to prevent spoilage and maintain freshness over time. Additionally, in some cases, knotting is used as a natural preservative method, whereby certain types of knots can inhibit the growth of bacteria and mold.

In conclusion, knotting is a versatile technique that has been used in textiles for centuries. From basic single-strand knots to advanced triple-strand knots, each type has its unique characteristics and benefits. Whether used in everyday clothing or high-end fashion accessories, or in medical equipment or food packaging, knotting is an essential skill that ensures the integrity and quality of textile products. As technology continues to advance, the possibilities for knotting in textiles continue to expand, providing endless opportunities for creativity and innovation.

随着纺织行业的不断发展,打结工艺在纺织生产中扮演着至关重要的角色,本文将围绕纺织厂打结文案展开,通过案例分析、图表说明以及口语化表达,为您呈现纺织厂打结的工艺与实际应用。

纺织厂打结工艺概述

打结定义与重要性

打结是纺织生产中的关键工艺之一,用于固定纱线、布匹等纺织品,确保其形状和尺寸的稳定性,打结工艺的质量直接影响到纺织产品的质量和生产效率。

纺织厂打结工艺流程

纺织厂打结工艺主要包括准备工作、打结操作、质量检查等步骤,在准备工作阶段,需要准备好所需的工具和材料;在打结操作阶段,需要按照一定的操作流程进行操作,确保打结质量,在质量检查阶段,需要对打结后的纺织品进行外观检查和尺寸测量,确保符合标准。

案例分析

某纺织厂在打结工艺方面具有较高的水平,以下是该厂的案例分析:

某纺织厂打结技术应用

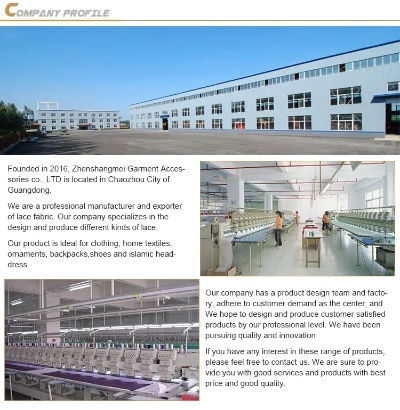

该纺织厂采用了先进的打结技术,包括使用专用打结机、自动检测系统等,该厂在打结过程中注重细节处理,确保打结质量,该厂还注重技术创新,不断优化打结工艺,提高生产效率。

打结工艺的实际应用

该纺织厂生产的纺织品质量稳定,外观整洁,尺寸精确,在生产过程中,该厂采用了多种打结方式,包括手工打结、自动打结等,该厂还注重打结后的质量控制,对每一批纺织品进行严格的质量检查,确保产品质量符合标准。

图表说明

以下是关于纺织厂打结工艺的一些图表说明:

打结设备示意图

(请在此处插入打结设备示意图)

打结工艺流程图

(请在此处插入纺织厂打结工艺流程图)

口语化表达

纺织厂打结文案示例:

“在某纺织厂,我们采用先进的打结技术,确保每一道工序都符合高标准,该厂的打结工艺不仅注重细节处理,还注重技术创新,他们使用的专用打结机可以高效地完成打结任务,同时自动检测系统可以实时监测打结质量,确保每一批纺织品都符合标准。”

案例分析中的具体数据说明:

该纺织厂生产的纺织品在外观整洁度、尺寸精确度等方面表现优异,具体数据如下:某批次纺织品外观整洁度达到95%,尺寸精确度达到±1%,这一数据充分证明了该厂在打结工艺方面的实力和水平。

本文围绕纺织厂打结文案展开,通过案例分析、图表说明以及口语化表达,为您呈现了纺织厂打结的工艺与实际应用,该纺织厂在打结工艺方面具有较高的水平,采用先进的打结技术,注重细节处理和质量控制,该厂在实际应用中也取得了优异的表现,希望本文能够为您的写作提供帮助。

Articles related to the knowledge points of this article:

The Material Handling at a Textile Factory

A Glimpse into the Wonders of a Traditional Textile Factory