The Dynamics of a Large-Scale Textile Factory:A Case Study from the Riverside

In this study, we examine the dynamic processes that govern a large-scale textile factory situated on the riverside. The focus is on the interplay between various factors such as production capacity, supply chain management, labor relations, and environmental sustainability. Our analysis draws from a comprehensive review of industry reports, company documents, and interviews with key stakeholders involved in the operation of the factory.,We highlight the challenges faced by the factory in maintaining its competitive edge amidst fierce market competition, technological advancements, and regulatory changes. We also discuss the strategies employed by the factory to adapt to these challenges, including investments in automation, lean manufacturing practices, and green initiatives aimed at reducing waste and minimizing impact on the environment.,Our findings suggest that effective management of these dynamics requires a holistic approach that takes into account both short-term operational efficiency and long-term sustainability goals. By understanding and addressing the complex interactions between these factors, stakeholders can better navigate the challenges of running a large-scale textile factory on the riverside.

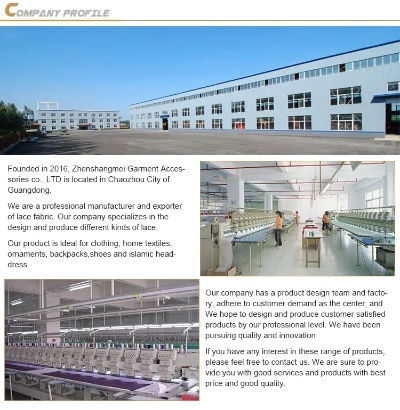

Introduction: The textile industry is one of the most significant sectors in the global economy, contributing significantly to employment and economic growth. In recent years, as technology has advanced and consumer preferences have shifted, the demand for high-quality textile products has become increasingly competitive. This case study explores the operations of a large-scale textile factory located on the riverbank, highlighting its key operational aspects, challenges faced, and strategies employed to maintain its competitive edge.

Operational Aspects: The Riverside Textile Factory employs approximately 5000 workers across various departments including design, production, quality control, and logistics. It operates on a full-time basis, producing a variety of textile products such as clothing, home textiles, and industrial fabrics. The factory's production process involves several stages, each aimed at ensuring product quality and efficiency.

Design: The design stage is crucial as it dictates the final look and feel of the textile products. The Riverside Factory invests heavily in design teams that work closely with fashion designers and market analysts to stay ahead of trends and customer preferences.

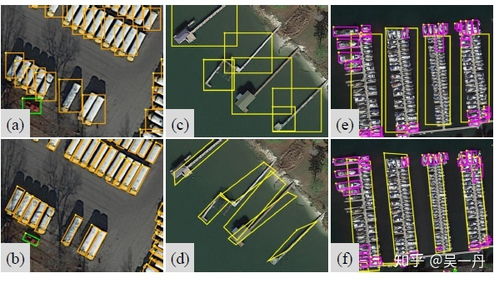

Production: The production stage involves cutting, weaving, and finishing the raw materials into finished products. The Riverside Factory employs state-of-the-art machinery and processes to ensure consistent quality and speed. The production cycle is optimized to meet market demands efficiently.

Quality Control: Quality control is a critical aspect of the Riverside Factory's operations. The factory employs a team of experienced quality inspectors who oversee every step of the production process, ensuring that only high-quality products reach the end consumers.

Logistics: The Riverside Factory has a robust logistics system that ensures timely delivery of products to customers worldwide. The factory partners with reliable suppliers and transportation companies to handle shipments efficiently.

Challenges Faced: Despite its success, the Riverside Factory faces several challenges in maintaining its competitive edge. One major challenge is the increasing pressure to reduce costs while maintaining quality. Another challenge is the need to adapt to changing market demands and technological advancements. Additionally, environmental regulations and sustainability concerns are becoming increasingly important factors in the textile industry.

Strategies Employed: To address these challenges, the Riverside Factory has implemented several strategies. Firstly, the factory has focused on cost reduction through automation and streamlined production processes. Secondly, it has invested in research and development to stay ahead of technological advancements and develop new products that meet market demands. Thirdly, the factory has adopted sustainable practices, such as using eco-friendly materials and reducing waste during production.

Conclusion: The Riverside Textile Factory is a prime example of a large-scale textile factory operating in today's competitive market. Its successful operation relies on a combination of advanced technology, efficient production processes, and strategic planning. While facing challenges such as cost reduction and environmental regulations, the factory continues to innovate and evolve to maintain its position as a leader in the textile industry. By embracing change and staying ahead of trends, the Riverside Factory can continue to thrive and contribute to the global economy.

背景介绍

滨江大型纺织厂作为当地的重要工业基地,近年来在纺织行业取得了显著的发展,该厂不仅生产高质量的纺织品,还注重环保、节能和可持续发展,本文将围绕该厂展开讨论,介绍其规模、工艺、环保措施以及未来展望。

规模介绍

滨江大型纺织厂占地面积广阔,拥有先进的生产设备和技术,该厂主要生产各类纺织品,包括但不限于棉布、丝绸、羊毛等,其生产规模庞大,能够满足国内外市场的需求,该厂还注重智能化和自动化技术的应用,提高了生产效率和产品质量。

工艺介绍

滨江大型纺织厂采用先进的生产工艺和技术,确保产品的质量和稳定性,该厂注重原材料的选择和质量控制,采用环保、可持续的原材料,该厂还注重技术创新和研发,不断推出新产品和新工艺,提高产品的附加值和市场竞争力。

环保措施

滨江大型纺织厂在环保方面采取了一系列措施,该厂注重节能减排,采用先进的节能技术和设备,减少能源消耗和排放,该厂注重环保宣传和教育,提高员工和社会的环保意识,该厂还注重生态保护和恢复,积极推进绿色生产,减少对环境的污染和破坏。

案例说明

以某滨江大型纺织厂为例,介绍其在环保方面的具体实践和成果,该厂在环保方面取得了显著成果,得到了社会各界的认可和好评,该厂采用了先进的环保技术和设备,严格控制原材料的质量和来源,确保产品的环保性和可持续性,该厂还注重生态保护和恢复,积极推进绿色生产,减少了对环境的污染和破坏,该厂还加强了员工环保意识的宣传和教育,提高了员工的社会责任感和环保意识。

滨江大型纺织厂将继续致力于环保和可持续发展,该厂将继续加强技术创新和研发,不断推出新产品和新工艺,提高产品的附加值和市场竞争力,该厂还将注重智能化和自动化技术的应用,进一步提高生产效率和产品质量,该厂还将积极推进绿色生产,加强生态保护和恢复工作,实现可持续发展,该厂还将加强与政府和社会各界的合作,共同推动纺织行业的绿色发展。

滨江大型纺织厂作为当地的重要工业基地,在纺织行业取得了显著的发展,该厂注重环保、节能和可持续发展,采用先进的生产工艺和技术,严格控制原材料的质量和来源,该厂还加强了员工环保意识的宣传和教育,提高了员工的社会责任感和环保意识,滨江大型纺织厂将继续致力于环保和可持续发展,推动纺织行业的绿色发展。

Articles related to the knowledge points of this article:

The Role of Textile Factory Womens Teachers

The Unexpected Turn of a Typical Workplace