Exploring the Quality Management of Beautiful Textiles in Guangxi

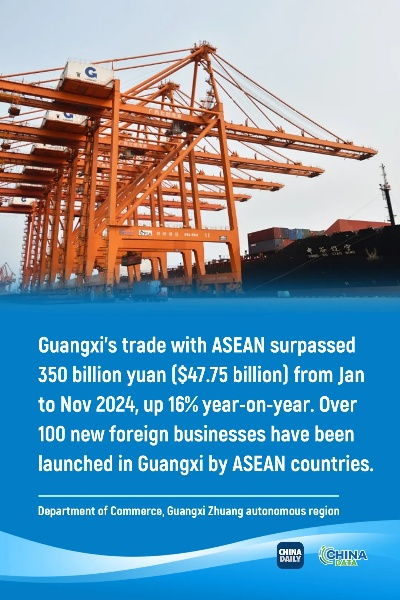

This paper aims to explore the quality management of beautiful textiles in Guangxi. The study analyzes the current situation and challenges faced by the industry, as well as the effectiveness of existing quality management systems. It highlights the importance of implementing a comprehensive quality management system that includes quality planning, implementation, and control processes. The study also recommends the use of advanced technologies such as RFID technology and machine learning to improve product quality and reduce waste. Finally, the study suggests that collaboration between different stakeholders, including manufacturers, distributors, and retailers, is essential for achieving long-term success in the industry.

Introduction: In the vibrant tapestry of China's textile industry, Guangxi stands out as a hub for excellence. With its unique geographical location and rich cultural heritage, Guangxi is home to some of the most exquisite and high-quality textile products in the country. In this article, we will delve into the intricate world of quality management in Guangxi's beautiful textiles, exploring various strategies that have been implemented to ensure the highest standards of quality are maintained throughout the production process.

Quality Management Strategies:

-

Standardization and Regulation: Guangxi's textile manufacturers adhere to strict standards set by international organizations such as the International Organization for Standardization (ISO) and the American National Standards Institute (ANSI). These standards ensure that every product meets the minimum requirements for quality, durability, and safety. For example, many factories use advanced dyeing and printing techniques to produce vibrant and long-lasting fabrics. Additionally, regular audits and inspections by independent quality control agencies help to maintain these standards.

-

Supplier Selection: The success of Guangxi's beautiful textiles hinges on the quality of raw materials used in their production. Therefore, selecting suppliers who prioritize sustainability and ethical practices is crucial. Many factories work closely with local communities to ensure fair labor practices and environmentally responsible practices during the production process. This not only enhances the product's reputation but also contributes to the overall well-being of the community.

-

Production Process Control: To guarantee consistent quality across all products, Guangxi's textile manufacturers employ advanced production technologies and processes. For instance, they use computer-controlled machinery to ensure precise measurements and consistent color consistency across batches. Additionally, the use of advanced dyeing and printing techniques allows for more complex designs to be produced without compromising quality.

-

Quality Assurance: Every step of the production process is carefully monitored to ensure that quality is maintained. From raw material testing to final inspection, every product undergoes rigorous quality checks. For example, some factories use machine vision technology to inspect fabrics for defects such as holes or tears before they are sent to the next stage of the production process.

-

Training and Education: To further improve quality management, many textile factories invest in training programs for their employees. These programs cover topics such as customer service, product knowledge, and best practices for maintaining quality standards throughout the production process. By investing in employee training, factories can ensure that their staff are equipped with the skills necessary to uphold the high standards of quality that define their brand.

Case Study: One such company that embodies the principles of quality management in Guangxi's beautiful textiles is "Sweet Dreams". Founded in 2008, this company has built a reputation for producing high-quality, sustainable textiles that meet both domestic and international standards. The company's dedication to quality extends beyond just meeting regulatory requirements; it involves a commitment to using eco-friendly materials and processes to minimize environmental impact.

Sweet Dreams takes great care in selecting its raw materials, ensuring that they come from reputable suppliers who prioritize sustainability and ethical practices. Additionally, the company employs state-of-the-art production technologies to ensure consistent quality across all products. Their focus on quality extends to their staff, with regular training sessions on customer service, product knowledge, and best practices for maintaining quality standards throughout the production process.

As a result of these efforts, Sweet Dreams has established itself as a leader in the sustainable textile industry, winning numerous awards for its innovative products and commitment to environmental responsibility. Their commitment to quality has not only helped them establish themselves as a trusted brand but has also contributed to the growth of the entire Guangxi textile industry.

Conclusion: In conclusion, the beauty of Guangxi's textiles lies in their ability to combine tradition with innovation, resulting in products that are not only visually stunning but also meet the highest standards of quality. Through standardization, supplier selection, production process control, quality assurance, and training and education, Guangxi's textile manufacturers have successfully achieved a balance between preserving their unique cultural heritage and delivering exceptional products that meet global consumer demands. As the industry continues to evolve, it is clear that the commitment to quality management will continue to be a cornerstone of Guangxi's beautiful textiles for years to come.

广西纺织品概述

广西以其丰富的自然资源和独特的地理环境,生产出了一批批优质的纺织品,在纺织品行业中,质量是企业的生命线,而广西的美观纺织品质量管理更是重中之重,本篇将围绕广西美观纺织品质量管理展开讨论。

广西纺织品质量管理的策略与措施

严格的质量标准体系

广西高度重视纺织品质量,建立了严格的质量标准体系,该体系涵盖了原材料采购、生产过程控制、成品检验等多个环节,确保每一件纺织品都符合国家或行业标准,广西还通过定期的质量检测和抽检,确保产品质量始终保持在较高水平。

先进的生产设备和技术

广西注重引进先进的生产设备和技术,以提高纺织品的生产效率和产品质量,广西的一些纺织企业引进了自动化生产线和智能检测设备,大大提高了生产效率和质量,广西还注重技术创新,不断研发新的纺织技术,提高纺织品的附加值和竞争力。

严格的质量管理体系

为了确保质量管理工作的有效实施,广西建立了严格的质量管理体系,该体系包括质量策划、质量控制、质量保证和质量改进等多个环节,每个环节都有明确的职责和流程,广西还通过定期的质量培训和考核,提高员工的质量意识和技能水平。

案例分析:广西美观纺织品质量管理案例

以某知名广西纺织企业为例,该企业在纺织品质量管理方面取得了显著成效,该企业注重原材料采购的质量控制,建立了严格的供应商管理制度,该企业还注重生产过程的控制,采用了先进的生产技术和管理方法,提高了生产效率和产品质量,该企业还注重质量管理体系的建立和完善,不断提高产品质量水平。

广西纺织品质量管理的实践与成效

提高产品质量水平

通过严格的质量管理措施和先进的生产设备和技术,广西的纺织品产品质量水平得到了显著提高,该企业的产品不仅符合国家标准,还获得了多项国内外知名奖项。

增强市场竞争力

广西的纺织品在市场上具有较高的竞争力,该企业的产品深受消费者喜爱,销售额和市场份额逐年增长,该企业的产品质量也得到了客户的高度认可和好评。

促进产业升级和发展

广西的纺织品质量管理实践促进了产业升级和发展,该企业的成功经验被其他企业借鉴和学习,推动了广西纺织产业的快速发展。

广西的美观纺织品质量管理是一项长期而艰巨的任务,为了不断提高产品质量水平,需要从多个方面入手,包括严格的质量标准体系、先进的生产设备和技术、严格的质量管理体系以及实践与成效等方面,还需要加强宣传和推广,提高消费者对广西纺织品质量的认知和认可度。

Articles related to the knowledge points of this article:

The Ultimate Guide to Choosing the Best Fabrics for Durable Wear

Navigating the Unpredictable:Strategies for Enhancing Textile Durability

The Story of Scentastic Textiles 盛祥纺织品的魅力与传奇

A Comprehensive Guide to the Price Range of Home Textiles in Jingan District