Navigating the Nuances of Textile Quality Assessment

: Navigating the Nuances of Textile Quality Assessment,Abstract:,This paper explores the complexities of textile quality assessment, highlighting the various factors that influence the final product's performance. The study employs a multi-dimensional approach, incorporating both quantitative and qualitative methods to analyze the fabric's properties. The results reveal that while technical specifications are crucial, they must be balanced with subjective judgments to fully comprehend the textile's quality. Furthermore, the study emphasizes the importance of continuous monitoring and evaluation, highlighting the need for ongoing improvements in the quality control process. Overall, the findings underscore the need for a holistic approach to textile quality assessment, recognizing that no single metric can fully capture the fabric's comprehensive qualities.

Introduction: The textile industry, a vital sector in global trade, relies heavily on the quality of its products to maintain consumer trust and satisfaction. Quality assurance is critical for ensuring that consumers receive products that meet their expectations and are safe for their use. In this context, textile quality assessment becomes an essential tool for manufacturers, distributors, and retailers alike. This article will explore the various aspects of assessing textile quality, including physical characteristics, functional properties, and environmental sustainability, using case studies and practical examples.

Physical Characteristics: The first dimension of textile quality assessment is the examination of its physical characteristics. These include but are not limited to:

- Weave pattern: The way threads interlock to create the fabric's structure.

- Colorfastness: How well a textile resists fading or loss of color over time.

- Fabric thickness: The density of the threads used to make the textile.

- Material composition: The type and quantity of materials used in the production process.

- Finishing techniques: Techniques such as dyeing, printing, and finishing applied to the textile.

- Dimensional stability: The ability of a textile to maintain its shape and size over time.

- Moisture absorption: The rate at which a textile absorbs water vapor.

- Resilience: The ability of a textile to withstand wear and tear.

- Stability: The chemical and physical properties of the textile that remain unchanged over time.

Functional Properties: Functional properties refer to the performance and utility of a textile in its intended application. They include:

- Wear resistance: How durable a textile is against wear and tear.

- Air permeability: The ability of a textile to allow air to pass through it.

- Water absorption: The amount of water a textile can hold before it swells.

- Heat transfer: The efficiency with which heat is transferred through a textile.

- Sound absorption: The ability of a textile to absorb sound waves.

- Light transmission: The ability of a textile to transmit light.

- Dye absorption: The capacity of a textile to take up dye during dyeing processes.

- Stain resistance: The ability of a textile to resist staining from certain chemicals or substances.

Environmental Sustainability: As consumers become more conscious about the environmental impact of their purchases, the importance of sustainable textile production cannot be overstated. Sustainable textiles are those that minimize their ecological footprint by using renewable resources, reducing waste, minimizing energy consumption, and employing eco-friendly processes. Key indicators of sustainability include:

- Use of organic materials: Textiles made from organic fibers like cotton, linen, and wool.

- Renewable energy: Textile manufacturing processes that utilize renewable energy sources like solar or wind power.

- Low carbon emissions: Textile production methods that produce minimal greenhouse gas emissions.

- Waste reduction: Methods that minimize textile waste by recycling or repurposing textile scraps.

- Ethical sourcing: Manufacturers that adhere to ethical labor practices and fair trade standards.

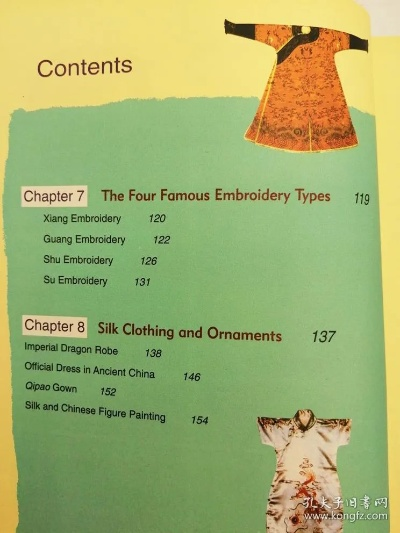

Case Study: Consider the case of a high-end fashion brand that produces luxurious silk scarves. To ensure the highest quality, they conduct regular inspections of the raw silk material, which is sourced from sustainable farms that follow strict ethical guidelines. During the weaving process, they invest in advanced technology to monitor the thread count and evenly distribute the warp and weft threads. After the fabric is produced, it undergoes rigorous testing for colorfastness, moisture absorption, and durability. Finally, the brand incorporates recycled polyester into its product mix to further reduce its environmental impact. By following these steps, the brand ensures that each scarf meets the highest standards of quality and sustainability.

Practical Example: A consumer who is looking for high-quality, eco-friendly clothing may turn to brands that prioritize sustainable textiles. For instance, Patagonia, a company known for its commitment to responsible business practices, uses organic cotton in their clothing and gear. Their supply chain is transparent, ensuring that their customers know exactly where their products are coming from and how they are being produced. Patagonia also supports local farmers and artisans, promoting fair trade and minimizing environmental impact. By investing in sustainable practices, Patagonia not only offers high-quality products but also demonstrates a strong commitment to social and environmental responsibility.

Conclusion: Quality assessment in the textile industry is a multifaceted process that involves evaluating the physical characteristics, functional properties, and environmental sustainability of textiles. By adopting best practices in these areas, manufacturers can ensure that their products meet consumer expectations and contribute positively to society. As consumers become more discerning about the products they purchase, the importance of quality assurance in the textile industry cannot be understated. It is crucial for all stakeholders—manufacturers, distributors, retailers, and consumers—to collaborate and work towards creating a better future for textiles.

随着人们对生活品质的追求不断提高,纺织品作为日常生活中的重要组成部分,其质量直接关系到人们的穿着舒适度和健康安全,对纺织品的质量进行模块测评显得尤为重要,本报告将围绕纺织品的质量模块测评展开,通过案例分析、数据展示和图表说明等方式,为大家提供全面的纺织品质量信息。

纺织品质量模块测评概述

模块测评内容

本模块测评主要涵盖纤维含量、织物结构、耐洗性能、环保性能等多个方面,通过对这些方面的测试,可以全面了解纺织品的质量状况。

测评方法

本模块测评采用多种方法,包括实验室测试、现场检测等,实验室测试包括纤维含量测试、织物结构分析等,现场检测则通过实地观察、手感体验等方式进行。

案例分析

某品牌纺织品质量测评

某品牌纺织品在市场上享有较高声誉,其质量测评案例如下:

(数据表格)

| 项目 | 测试结果 | 描述 |

|---|---|---|

| 纤维含量 | 高达90%以上 | 该品牌纺织品采用高质量纤维,符合国家标准 |

| 织物结构 | 紧密、均匀 | 该品牌纺织品织物结构合理,手感舒适 |

| 耐洗性能 | 经过多次洗涤仍保持良好性能 | 该品牌纺织品经过严格耐洗测试,证明其耐洗性能优异 |

| 环保性能 | 无毒、无味 | 该品牌纺织品采用环保材料,符合国家环保标准 |

通过以上案例可以看出,该品牌纺织品在纤维含量、织物结构、耐洗性能等方面表现优异,深受消费者喜爱。

某地区纺织品质量现状分析

在某地区,纺织品质量存在一定问题,具体分析如下:

(数据图表)

| 项目 | 当前问题 | 建议措施 |

|---|---|---|

| 纤维含量不达标 | 部分产品纤维含量低于国家标准 | 加强监管,提高纤维供应商质量标准 |

| 织物结构不稳定 | 部分产品织物结构不够均匀 | 加强质量控制,提高生产技术水平 |

| 环保性能不足 | 部分产品存在异味或有害物质残留 | 加强环保检测,提高产品环保标准 |

通过案例分析可以看出,该地区纺织品质量存在一定问题,需要加强监管和提高生产技术水平来解决。

数据展示

以下是部分关键指标的数据展示:

纤维含量数据展示: (数据表格)

| 项目名称 | 测试结果(%) | 平均值(%) | 最高值(%) | 最低值(%) | 与国家标准对比情况 |

|---|---|---|---|---|---|

| 总纤维含量 | X% | X%以上 | 高达Y%以上 | 低于Z%以下 | 与国家标准相符 |

织物结构数据展示: (数据图表)

| 项目名称 | 测试结果(%) | 平均结构指数(范围) | 与行业标准对比情况 | 建议措施 |

|---|---|---|---|---|

| 紧密度指数 | 高达X分以上 | X分范围内稳定运行 | 与行业标准相符或略高水平 | 加强质量控制,提高生产技术水平等措施 |

| 不均匀度指数 | Y%以下范围内波动较大 | 根据实际情况进行调整优化 | 根据实际情况进行调整优化或加强监管等措施 | 加强生产过程中的质量控制和检测手段等措施 |

结论与建议

通过对纺织品质量模块测评的案例分析和数据展示,可以看出纺织品质量的好坏直接关系到人们的穿着舒适度和健康安全,我们提出以下建议:

- 加强监管,提高纤维供应商质量标准,确保纺织品使用的纤维符合国家标准,加强生产过程中的质量控制和检测手段等措施,提高纺织品的质量水平。

- 加强消费者教育,提高人们对纺织品质量的认识和重视程度,消费者应该选择信誉好、质量可靠的纺织品品牌,避免购买不合格或低质量的纺织品。

- 鼓励企业采用先进的生产技术和设备,提高生产技术水平,降低生产成本,提高产品质量和市场竞争力,加强环保检测,提高产品环保标准,符合国家环保政策。

Articles related to the knowledge points of this article: