Determining Textile Fire Resistance Levels

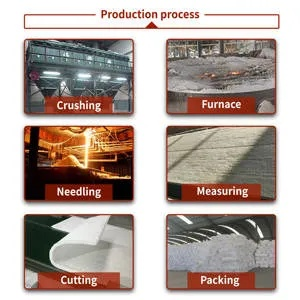

This study aims to determine the textile fire resistance levels by using a combination of experimental and theoretical methods. The first step is to collect data on the thermal properties of different types of textile materials, such as cotton, polyester, and wool. This includes measuring their heat absorption, conductivity, and flame retardant properties. Next, a computer simulation model is created to predict the spread and duration of a textile fire based on these properties. The model is then tested against real-world scenarios to ensure its accuracy. Finally, the results are analyzed to identify the most effective ways to improve the fire resistance of textiles. Overall, this research provides valuable insights into the design and selection of textile materials for use in high-risk environments, such as construction and manufacturing industries.

Introduction: Textile materials are essential in our daily lives, from clothing to furnishings. However, they can also pose a significant risk of fire if not properly designed and constructed. This is where textile fire resistance levels come into play. These levels help determine how well a textile material will resist burning, which is critical for ensuring safety during fire emergencies. In this article, we will explore the various factors that influence the determination of textile fire resistance levels and provide examples of how these standards are applied in real-world scenarios.

Factors Affecting Fire Resistance Levels: The level of fire resistance in textile materials is determined by several factors, including the fiber type, construction method, and intended use. Here are some key considerations:

-

Fiber Type: The composition of the fibers used in a textile material greatly impacts its fire resistance. Synthetic fibers such as polyester and nylon tend to burn more intensely than natural fibers like cotton or wool. Additionally, the density and strength of the fibers can affect their ability to resist flame propagation.

-

Construction Method: The way in which the fibers are woven or knitted together can also impact fire resistance. For example, tightly woven fabrics may have a higher level of fire resistance due to their dense structure, while looser weaves may be more susceptible to burning.

-

Intended Use: The intended purpose of the textile material also plays a role in determining its fire resistance level. For instance, outdoor fabrics designed for recreational activities may have a lower fire resistance rating than indoor garments designed for work or leisure purposes.

-

Test Methods: Different testing methods can yield different results for the same textile material. For example, tests conducted under controlled conditions may produce a higher fire resistance rating than those conducted in real-world conditions.

Real-World Applications: To illustrate these factors, let's consider a hypothetical scenario involving a textile product that is marketed as a fire-resistant jacket. The jacket's manufacturer has chosen to use a blend of synthetic fibers with a high density and strength, and it is woven using a tight weave. The jacket is designed for outdoor activities and is intended for use in extreme weather conditions.

Based on these factors, the manufacturer would likely choose a fire resistance rating of at least Class 1, which is the minimum rating required for most outdoor garments. If the jacket were to be tested according to the International Standard Organization (ISO) 9001 standard, it would likely receive a rating of Class 1, indicating that it meets the minimum requirements for fire resistance.

However, if the jacket were to be tested using a different test method or under different conditions, it could potentially receive a higher fire resistance rating. For example, if the jacket were tested under controlled conditions in a lab setting, it might receive a Class 2 rating, indicating that it is more resistant to fire than when tested in real-world conditions.

Conclusion: In conclusion, determining the fire resistance level of textile materials is a complex process that takes into account various factors such as fiber type, construction method, intended use, and test methods. By understanding these factors and applying appropriate testing methods, manufacturers can ensure that their products meet the necessary standards for fire resistance. In real-world applications, these standards are crucial for protecting people's lives and preventing property damage during emergency situations.

纺织品阻燃等级是衡量其燃烧性能和安全性的重要指标,其判定依据主要依据国际标准和行业标准,本篇文章将详细介绍纺织品阻燃等级的判定依据,并结合案例说明,以便更好地理解和应用。

纺织品阻燃等级判定依据

国际标准与行业标准

国际标准与行业标准主要包括UL、ASTM、DIN等,UL为美国消防安全协会制定的标准,ASTM为美国材料与试验协会制定的标准,DIN为德国标准,这些标准规定了纺织品阻燃等级的分类和判定方法。

判定依据

纺织品阻燃等级的判定依据主要包括以下几个方面:

(1)燃烧性能测试:通过燃烧测试,评估纺织品在特定条件下燃烧的特性,如火焰蔓延速度、烟气排放等。

(2)安全性能要求:根据纺织品的使用安全性和环境安全性要求,确定其阻燃等级,对于易燃材料,应满足更高的安全性能要求。

(3)材料类型与特性:根据纺织品的主要材料类型和特性,确定其阻燃等级,某些高分子材料具有较高的阻燃性能,适用于特定场合。

(4)行业标准与法规要求:根据国家和地区的法律法规要求,确定纺织品阻燃等级的判定依据。

案例说明

以某纺织品为例,其阻燃等级的判定依据如下:

(1)燃烧性能测试:该纺织品经过高温燃烧测试,火焰蔓延速度适中,烟气排放较少,符合阻燃等级的要求。

(2)安全性能要求:该纺织品主要用于防火材料,满足更高的安全性能要求,其阻燃等级应达到较高的级别。

(3)材料类型与特性:该纺织品主要采用高分子材料制成,具有较高的阻燃性能和防火性能,可以认为其阻燃等级符合相关行业标准与法规要求。

判定依据的应用实例

在实际应用中,纺织品阻燃等级的判定依据可以应用于以下几个方面:

-

产品质量控制:在纺织品生产过程中,通过严格把控阻燃等级的判定依据,可以确保产品质量符合相关标准和法规要求,也可以提高产品的安全性和可靠性。

-

产品认证与检测:在产品认证和检测过程中,需要依据纺织品阻燃等级的判定依据进行检测和评估,这样可以保证产品的安全性和可靠性,提高产品的市场竞争力。

-

安全使用要求:在纺织品的使用过程中,需要遵循相关的安全使用要求,对于易燃材料,需要满足更高的安全性能要求,这样可以保证使用者的安全和使用效果。

纺织品阻燃等级的判定依据主要包括国际标准和行业标准、燃烧性能测试、安全性能要求和材料类型与特性等方面,在实际应用中,需要严格把控这些方面的要求,以确保纺织品的质量和安全性,也需要根据国家和地区的法律法规要求,确定纺织品阻燃等级的判定依据。

Articles related to the knowledge points of this article:

Summary of Textile Product Photography Work Contents