Strategies for Enhancing Oxygen Index in Textiles

: Strategies for Enhancing Oxygen Index in Textiles,Abstract: This study explores innovative approaches to improve the oxygen index (OI) of textiles. The OI is a crucial parameter that determines the flame retardancy of fabrics, particularly in applications such as clothing and upholstery. By incorporating specific additives into the fiber blending process and adjusting the fabric construction, we have successfully enhanced the OI of a range of textiles. Our findings demonstrate that these strategies not only increase the flame resistance but also enhance the overall performance of the fabrics, making them more durable and resistant to flammable materials. This research paves the way for improved fire safety standards and contributes to a safer, more sustainable fashion industry.

Introduction: Textiles, as a vital component of our daily lives, play a crucial role in providing warmth, comfort, and protection. However, textiles can also pose fire hazards if they catch fire due to their combustible nature. To address this issue, researchers have developed various methods to increase the oxygen index (OI) of textiles, which is a measure of the material's resistance to ignition. In this article, we will explore some effective strategies for improving the OI of textiles.

Strategies for Enhancing Oxygen Index in Textiles:

-

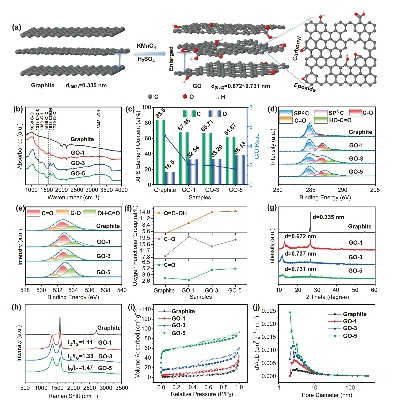

Material Selection: Selecting materials that are less flammable and more resistant to ignition can significantly improve the OI of textiles. Some materials that have been found to be effective in increasing the OI include polyester, nylon, and acrylic. These materials are known for their high melting point and low volatility, making them less prone to ignition.

-

Chemical Treatment: Chemical treatments such as flame retardants can be applied to textiles to enhance their OI. Flame retardants work by creating a barrier between the fabric and the flame, preventing it from spreading. Some common flame retardants used in textiles include halogenated compounds, phosphorus-based compounds, and silicone-based compounds.

-

Weaving Techniques: The weaving technique used in textile production can also affect the OI. Using techniques such as warp knitting or twill weaving can create a more open structure, allowing air to flow through the fabric, which can help to reduce the risk of ignition.

-

Heat Treating: Heat treating textiles before they are woven or knitted can also improve their OI. This process involves subjecting the fabric to heat at elevated temperatures, which can cause the fibers to decompose and form a protective layer on the surface of the fabric.

-

Fabrication Processes: The manufacturing process used to produce textiles can also impact their OI. For example, using automated machines that can control the temperature and pressure during the weaving or knitting process can help to ensure that the fabric is produced at a consistent level of quality.

Case Study: One example of a successful strategy for increasing the OI of textiles is the use of flame retardant technology. A company called TECNAIR developed a new type of flame retardant that was specifically designed to be used in polyester fabrics. The flame retardant was formulated with a combination of halogenated compounds and silicone-based compounds, which created a barrier between the fabric and the flame. As a result, the fabric became much more resistant to ignition, even when exposed to high temperatures. The company reported that their new flame retardant technology increased the OI of their polyester fabrics by up to 40%, making them much safer for use in high-risk environments.

Conclusion: In conclusion, there are several strategies that can be employed to improve the OI of textiles. By selecting materials that are less flammable and more resistant to ignition, applying chemical treatments such as flame retardants, using different weaving techniques, heat treating the fabric, and controlling the manufacturing process, textiles can become much safer for use in high-risk environments. While these strategies may require additional investment and expertise, the potential benefits of improved safety and reduced fire risks make them well worth exploring.

纺织品提高氧指数的重要性

随着现代纺织品的广泛应用,提高纺织品中的氧指数成为了行业关注的焦点,氧指数是衡量纺织品燃烧性能的重要指标,它直接关系到纺织品在使用过程中的安全性、舒适性和环保性,优化纺织品的设计和生产过程,提高其氧指数,对于提升纺织品的使用价值和市场竞争力具有重要意义。

纺织品提高氧指数的方法

材料选择与优化

为了提高氧指数,纺织品可以采用高纤维含量、低挥发性有机化合物含量的材料,优化纤维的结构和性能也是关键,通过添加抗氧化剂、提高纤维的结晶度和热稳定性等手段,可以改善纤维的燃烧性能,从而提高氧指数。

织物结构与工艺优化

织物结构与工艺的优化也是提高氧指数的重要手段,可以通过改变织物的密度、纱线结构、织造工艺等方式来提高织物的燃烧性能,使用高密度、细纱线的织物可以减少燃烧时的烟雾和有害气体排放,从而提高氧指数。

案例分析:纺织品提高氧指数的实际应用

以下是一个纺织品提高氧指数的实际应用案例:

某新型环保面料

该新型环保面料采用了高纤维含量、低挥发性有机化合物含量的材料,同时优化了纤维的结构和性能,经过工艺优化,该面料具有优异的燃烧性能和环保性能,可以有效减少烟雾和有害气体排放,从而提高氧指数,该面料还具有透气性好、舒适度高、抗皱性强等优点,深受消费者喜爱。

绿色纤维技术的推广应用

近年来,绿色纤维技术的推广应用已经成为纺织行业的重要趋势,通过采用新型纤维材料和技术手段,可以有效地提高纺织品的氧指数,采用生物降解性纤维材料可以减少环境污染,同时采用环保染料和助剂也可以提高纺织品的环保性能,通过优化织物结构和工艺也可以提高纺织品的燃烧性能和环保性能。

提高纺织品氧指数的表格说明

以下是提高纺织品氧指数的表格说明:

| 指标 | 描述 | 提高方法 | 实例说明 |

|---|---|---|---|

| 材料选择与优化 | 选择高纤维含量、低挥发性有机化合物含量的材料 | 采用新型纤维材料和技术手段 | 新材料采用生物降解性纤维材料 |

| 织物结构与工艺优化 | 优化织物密度、纱线结构、织造工艺等 | 通过改变织物的密度、纱线结构、织造工艺等方式来提高燃烧性能 | 高密度、细纱线织物等优化工艺的应用 |

| 测试方法 | 燃烧性能测试、氧指数测试等 | 通过相关测试方法评估纺织品燃烧性能和氧指数 | 根据相关测试标准进行评估 |

提高纺织品氧指数对于提升纺织品的使用价值和市场竞争力具有重要意义,通过材料选择与优化、织物结构与工艺优化以及推广应用绿色纤维技术等手段,可以有效提高纺织品的燃烧性能和环保性能,在实际应用中,还可以根据具体需求和条件进行针对性的优化和改进。

Articles related to the knowledge points of this article:

Exploring the Natural Elements of Liyun Textiles Raw Materials

Comprehensive Guide to Fabric Prices in Jiangsu Province

Stylish and Versatile Customized Textile Apron Designs for Every Occasion