Understanding and Complying with Textile Crease Test Methods

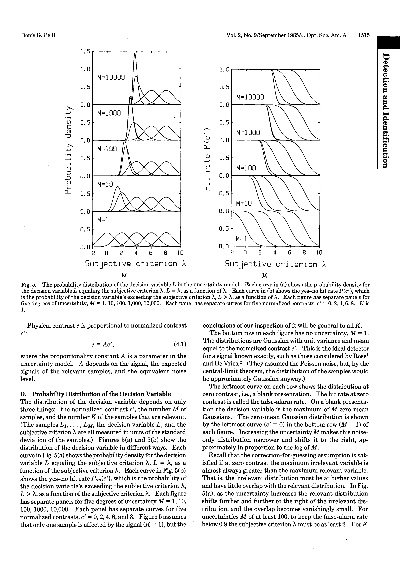

This paper discusses the understanding and compliance of textile crease test methods. The main content includes the definition, purpose, scope, testing principle, and basic steps of the textile crease test methods. It also introduces the characteristics of different types of textile crease test methods, such as the tensile crease test method, the static crease test method, the dynamic crease test method, and the multi-directional crease test method. Furthermore, it explores the application of textile crease test methods in the textile industry, such as the determination of fabric properties, the evaluation of fabric quality, and the development of new fabric products. Finally, the paper points out that to ensure the accuracy and reliability of textile crease test results, it is necessary to strictly follow the testing procedures and standards, and to use appropriate testing equipment and materials.

Introduction: Textiles are an integral part of our daily lives, from clothing to furnishings. One of the most visible signs of quality is the way they fold and crease. The ability to create a visual representation of these creases is crucial for assessing the durability and quality of a textile product. In this video, we will discuss the various methods used to test textiles for creases and how to interpret the results.

Methodology: There are several methods used to test textiles for creases, including manual and automated methods. Manual methods involve manually pressing and pulling on the fabric to create creases, while automated methods use machines to create consistent creases at a faster rate.

Manual Method: The manual method involves using a handheld tool to create small creases on the fabric. This method is commonly used for testing clothing and other soft fabrics. The process involves gently pressing down on the fabric with the tool, creating a small crease that can be easily seen. The depth and size of the crease are measured using a ruler or measuring tape.

Automated Method: The automated method uses a machine to create consistent creases on the fabric. This method is commonly used for testing heavier fabrics such as denim or carpets. The process involves placing the fabric into a machine and pressing it against a surface to create a crease. The depth and size of the crease are measured using a camera or sensor.

Interpretation of Results: Once the creases have been created, the next step is to interpret the results. The depth and size of the creases can indicate the strength and durability of the fabric. For example, lighter fabrics will create smaller creases, while heavier fabrics will create larger creases. Additionally, the color and texture of the fabric can also affect the appearance of the creases.

Case Study: Let's take a look at an example of how to interpret the results of a textile crease test. Suppose we were testing a shirt made from a lightweight cotton fabric. We would create small creases on the fabric using a handheld tool, measuring the depth and size of each crease. Based on the results, we would determine if the shirt was durable enough to withstand normal wear and tear.

Conclusion: Textile crease testing is an important aspect of ensuring the quality and durability of textile products. By understanding the different methods used to test textiles for creases and interpreting the results, we can make informed decisions about which products to purchase and how to care for them properly. Remember, the appearance of creases can also provide insight into the quality of the fabric itself.

视频开头

(画面展示各种纺织品样品,随后展示测试方法视频)

【视频开头】

大家好,今天我们将一起探讨纺织品褶皱测试方法的重要性及其在实际操作中的应用,我们将通过视频的形式详细介绍这一重要测试方法。

纺织品褶皱测试方法概述

(一)测试目的

纺织品褶皱测试是评估纺织品在各种使用条件下的抗皱性能的重要手段,通过褶皱测试,可以了解纺织品在拉伸、折叠、扭曲等不同使用情境下的抗皱性能,为消费者提供购买依据。

(二)测试原理

纺织品褶皱测试主要依据的是纺织品在受到外力作用时产生的褶皱程度,通常采用一系列的仪器设备进行测试,包括压力传感器、测量仪表等,通过观察和记录纺织品在特定条件下的褶皱情况,得出其抗皱性能的评估结果。

(三)测试步骤

- 选择合适的测试样品,确保其尺寸、材质和用途符合要求。

- 将样品放置在测试设备中,设置相应的测试参数。

- 对样品进行连续的拉伸和折叠测试,观察并记录其褶皱情况。

- 根据测试结果,对样品进行综合评价,给出相应的抗皱性能等级。

具体测试方法视频详解

(一)准备工作

在进行纺织品褶皱测试之前,需要准备以下工具和材料:

- 测试设备:包括压力传感器、测量仪表等。

- 样品台:用于放置待测试的纺织品样品。

- 测试环境:确保测试环境温度、湿度适宜,避免外界因素干扰。

(二)操作步骤视频详解

- 选择合适的测试样品:根据实际需求选择合适的纺织品样品,确保其尺寸、材质和用途符合要求。

- 将样品放置在测试设备中:将样品放置在样品台上,确保样品平整无褶皱。

- 设置测试参数:根据样品的具体情况,设置相应的拉伸速度、折叠次数等参数。

- 进行连续的褶皱测试:启动测试设备,进行连续的褶皱测试,观察并记录纺织品在拉伸和折叠过程中的褶皱情况。

- 分析测试结果:根据测试结果,对纺织品进行综合评价,给出相应的抗皱性能等级,可以按照以下标准进行评价:轻微褶皱、中度褶皱、严重褶皱等。

案例说明

(一)案例一:纺织品褶皱测试实例分析

某品牌的新款丝绸面料经过褶皱测试后发现,其在特定条件下具有较好的抗皱性能,通过连续的拉伸和折叠测试,该面料在受到外力作用时产生的褶皱程度较低,表明其具有良好的抗皱性能,该品牌可以根据这一结果为消费者提供购买依据,提高产品的市场竞争力。

(二)案例二:其他纺织品褶皱测试案例分享

在实际应用中,还有其他多种纺织品可以采用类似的褶皱测试方法进行评估,某些防水面料在经过长时间使用后可能会出现轻微褶皱,但通过适当的处理和保养措施,仍然可以保持良好的抗皱性能,在进行纺织品评估时,需要根据具体需求选择合适的测试方法。

总结与展望

通过本次视频解说,我们详细介绍了纺织品褶皱测试方法的重要性及其在实际操作中的应用,我们也通过案例说明的方式,为大家提供了实际操作的参考依据,随着纺织品的不断发展和更新换代,对于纺织品抗皱性能的要求也越来越高,我们需要在生产过程中加强质量控制,提高纺织品的质量水平,满足消费者的需求。

Articles related to the knowledge points of this article:

在商丘这片繁华的纺织品一条街,棉绸批发市场以其丰富的商品种类和优质的服务吸引了无数商贾云集。今天,让我们一同走进这个充满活力的市场,探索其魅力所在

The Essentials of Cotton Textiles