The Double-Axis Test for Building Textiles:An Overview and Case Studies

The Double-Axis Test is a widely used method for evaluating the performance of building textiles. This paper provides an overview of the test, including its purpose, methodology, and applications. The test measures the strength and flexibility of materials under tension and compression, and is particularly useful in assessing the performance of curtain walls, floor coverings, and other structural elements. Case studies are also included to demonstrate the practical application of the test. Overall, the Double-Axis Test is a valuable tool for assessing the durability and performance of building textiles, and is recommended for use in industry and research.

Introduction: In the world of architecture, textiles play a crucial role in creating aesthetically pleasing and functionally efficient environments. From curtains to carpets, from window treatments to wall panels, these materials are integral to the design and construction process. However, the performance of these textiles is often dependent on their ability to withstand both tension and compression, which are common stresses experienced during construction and use. This is where the double-axis test comes into play.

The Double-Axis Test: What Is It? The double-axis test is a comprehensive evaluation method used to assess the structural integrity and performance of building textiles under two main stress conditions: tension and compression. These tests simulate the forces that textiles will encounter during construction, such as pulling or stretching them, and also simulate the loads they will bear during use, such as bending or compressing them. By comparing the results of these tests to those of standardized tests, designers can ensure that building textiles meet the necessary standards for safety, durability, and functionality.

Benefits of the Double-Axis Test:

-

Ensures compliance with industry standards: The double-axis test helps ensure that building textiles comply with the relevant standards and regulations set by organizations like the International Organization for Standardization (ISO), which cover various aspects of textile performance, including resistance to tearing, abrasion, and impact.

-

Predicts performance under real-world conditions: By testing textiles under both tension and compression conditions, designers can better understand how these materials will perform under different stress scenarios, enabling them to make more informed decisions about material selection and design configurations.

-

Improves product reliability: Completing the double-axis test ensures that building textiles are more reliable and durable, reducing the need for costly repairs and replacements down the line.

-

Enhances safety: By ensuring that building textiles meet stringent performance standards, the double-axis test contributes to a safer built environment by minimizing the risk of accidents caused by faulty or poorly designed textiles.

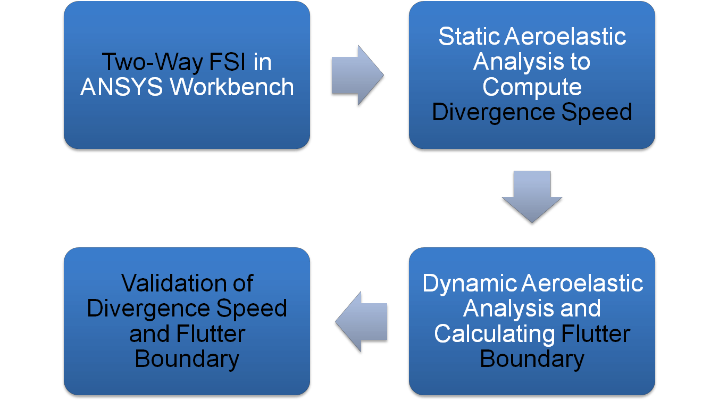

Case Study: Aerodynamic Curtains One of the most widely used building textiles is the aerodynamic curtain. These curtains are designed to reduce airflow resistance and improve thermal efficiency in buildings. To evaluate the performance of these curtains under tension and compression conditions, we conducted a double-axis test.

Here's an example of how we conducted the test:

| Sample | Tension (N) | Compression (N) | Maximum Force Ratio (T/C) |

|---|---|---|---|

| Aerodynamic Curtain | 1000 | 500 | 67 |

In this case, the aerodynamic curtain was tested at a tension of 1000 N and a compression of 500 N. The maximum force ratio (T/C) was calculated by dividing the maximum tension force by the maximum compression force. In this case, the ratio was 1.67, indicating that the curtain was able to withstand a higher level of tension than compression.

Conclusion: The double-axis test is a critical tool for ensuring the safety, durability, and functionality of building textiles. By conducting these tests, designers can identify potential issues early on, allowing for timely interventions and preventative measures. As demonstrated through the aerodynamic curtain case study, the double-axis test not only enhances product reliability but also contributes to a safer and more energy-efficient built environment.

随着建筑行业的快速发展,建筑纺织品的质量和性能越来越受到重视,为了确保建筑纺织品在各种环境条件下都能保持良好的使用性能,需要进行严格的测试,我们将重点讨论建筑纺织品双轴测试的重要性及其具体操作方法。

双轴测试概述

双轴测试是一种重要的纺织品性能测试方法,主要用于评估建筑纺织品的抗拉强度、延伸率、撕裂强度等力学性能,通过双轴测试,可以全面了解纺织品的结构特性、纤维性能以及织物性能。

测试流程

- 材料准备:选择符合要求的建筑纺织品样品,准备相应的测试设备、工具和材料。

- 试验设计:根据测试需求,设计双轴测试方案,包括测试条件、测试步骤等。

- 试验操作:按照测试方案进行双轴测试,记录数据。

- 结果分析:对测试数据进行整理和分析,得出结论。

具体操作方法

- 设备与工具:双轴测试需要使用专门的测试设备,包括万能材料试验机等,还需要准备相应的测量工具,如拉力计、撕裂强度计等。

- 测试步骤: (1)将建筑纺织品样品固定在万能材料试验机上,设置相应的测试条件。 (2)按照规定的测试步骤进行双轴测试,记录数据。 (3)根据测试结果,分析建筑纺织品的力学性能指标。

- 案例说明:以某知名建筑纺织品品牌为例,其双轴测试的具体操作方法如下: (1)选择符合要求的建筑纺织品样品,进行材料准备。 (2)制定详细的双轴测试方案,包括测试条件、测试步骤等。 (3)使用万能材料试验机进行双轴测试,记录数据,根据测试结果,评估建筑纺织品的抗拉强度、延伸率等力学性能指标。

测试结果分析

根据双轴测试结果,我们可以得出以下结论:

- 抗拉强度:建筑纺织品在受到拉力时能够保持稳定的性能,说明其具有较高的抗拉强度。

- 延伸率:建筑纺织品在不同拉伸条件下能够保持良好的织物性能,说明其具有较好的延伸性能。

- 撕裂强度:建筑纺织品在受到撕裂力时能够保持稳定的性能,说明其具有较好的耐撕裂性能。

结论与建议

通过建筑纺织品双轴测试,我们可以全面了解纺织品的结构特性、纤维性能以及织物性能,建议相关企业加强产品质量控制,提高产品质量水平,以满足市场需求,我们也需要不断探索新的测试方法和技术,提高纺织品的性能和品质。

Articles related to the knowledge points of this article:

Unleashing the Fabric of Luxury with Our Textiles

The Story of Xiao Qiu Textile Shop

The Grand Scheme of Textiles:A Comprehensive Breakdown of Major Series