The Future of Green Textiles in Nanjings Welding Industry

In the context of the fast-paced development of Nanjing's welding industry, green textiles have become a crucial aspect for sustainable production. This paper explores the future prospects and challenges of green textiles in the welding industry, focusing on their potential impact on energy efficiency, environmental protection, and economic benefits.,Green textiles refer to materials that are made from renewable resources, have low environmental impact, and can be easily recycled or reused. They play a significant role in reducing carbon emissions and promoting eco-friendly practices within the welding industry. By adopting green textiles, welders can improve energy efficiency, reduce waste, and protect the environment while also enhancing their competitiveness in the market.,However, there are still challenges associated with the implementation of green textiles in the welding industry. These include the high cost of transitioning to green textiles, the lack of awareness among welders and manufacturers, and the need for regulatory frameworks and standards to support the adoption of green textiles.,To overcome these challenges, it is essential for the government, industry, and research institutions to work together to promote the adoption of green textiles in the welding industry. This can be achieved through education and training programs, incentives and subsidies, and collaboration between different stakeholders.,In conclusion, the adoption of green textiles in the welding industry has the potential to bring about significant environmental and economic benefits. However, it requires concerted efforts from all stakeholders to overcome the challenges and ensure their successful implementation.

Nanjing, the capital city of Jiangsu Province in China, is known for its rich cultural heritage and modern advancements. One such area where green initiatives are gaining momentum is in the field of welding and textile processing. This topic explores how the integration of green technologies into the welding industry in Nanjing could transform the local economy and environment.

Green Textiles in Welding: The Role of Technology

The traditional welding process involves the use of toxic fumes, harmful chemicals, and high-temperature flames, which can pose a significant threat to workers' health and the environment. However, with the advent of green technology, welding has become more sustainable and environmentally friendly.

One example of this is the use of laser welding, which uses laser beams to heat up the material being welded. This method eliminates the need for cutting or grinding, reducing waste and emissions. Additionally, laser welding produces less heat than traditional welding methods, which helps to minimize thermal damage to surrounding materials.

Another innovation in green welding is the use of water-based fluxes. These fluxes contain fewer toxic chemicals than traditional fluxes, making them safer for workers and the environment. They also reduce the amount of water required for cleaning and disposal, further minimizing pollution.

Green Textiles in Welding: Sustainable Practices

In addition to technological advancements, the welding industry in Nanjing is also committed to adopting sustainable practices. For example, some companies have implemented recycling programs that reuse scrap metal from previous projects. This not only reduces waste but also saves resources and energy.

Another way that green textiles are being integrated into welding is through the use of eco-friendly materials. Some companies are now using recycled polyester fabrics for their welding masks, which are designed to protect workers from dust and other hazards while still allowing them to breathe easily.

Green Textiles in Welding: Economic Benefits

The adoption of green technologies in the welding industry not only benefits the environment but also offers economic advantages. By reducing waste and emissions, companies can save money on costs associated with environmental regulations and insurance premiums.

Moreover, investing in green technologies can attract new customers and partners who share the same values. As consumers become more aware of the impact of their purchases on the environment, companies that prioritize sustainability will be more likely to win market share.

Conclusion: A Green Future for Welding in Nanjing

In conclusion, the integration of green textiles into the welding industry in Nanjing is a promising development that has the potential to transform both the local economy and environment. By adopting sustainable practices and technological innovations, companies can create a more efficient, safe, and environmentally friendly workplace. As Nanjing continues to embrace this approach, it stands to benefit from a bright future in the global marketplace.

南京作为中国的历史文化名城,近年来在绿色纺织品的焊接加工领域取得了显著成就,本篇文章将围绕南京绿色纺织品焊接加工的主题,通过英文口语化的方式为您详细介绍。

南京绿色纺织品焊接加工概述

绿色纺织品定义

绿色纺织品是指采用环保、可持续的材料和技术进行生产,注重环境保护和资源节约的纺织品。

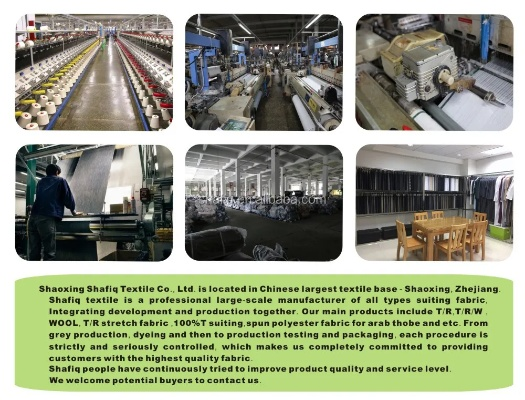

南京绿色纺织品焊接加工现状

南京作为纺织业的重要城市,在绿色纺织品焊接加工方面取得了显著进展,采用环保材料和技术,实现了高效、环保的焊接加工。

南京绿色纺织品焊接加工案例分析

某品牌绿色纺织品焊接加工过程

某品牌在南京采用先进的焊接技术,使用环保材料进行纺织品焊接加工,该过程注重环保和资源节约,确保产品质量的同时,也符合可持续发展的要求。

南京绿色纺织品焊接加工案例分析——某品牌过程展示

| 步骤 | 环保材料使用 | 焊接工艺 | 环保效果 | 产品质量与性能提升 |

|---|---|---|---|---|

| 材料选择 | 使用可降解材料 | 高频焊接技术 | 减少环境污染,符合可持续发展要求 | 提高产品质量,满足市场需求 |

| 生产流程优化 | 减少能源消耗,降低废水排放 | 提高生产效率,减少废弃物产生 | 提高生产效率,降低生产成本 | 提高产品附加值,满足消费者需求 |

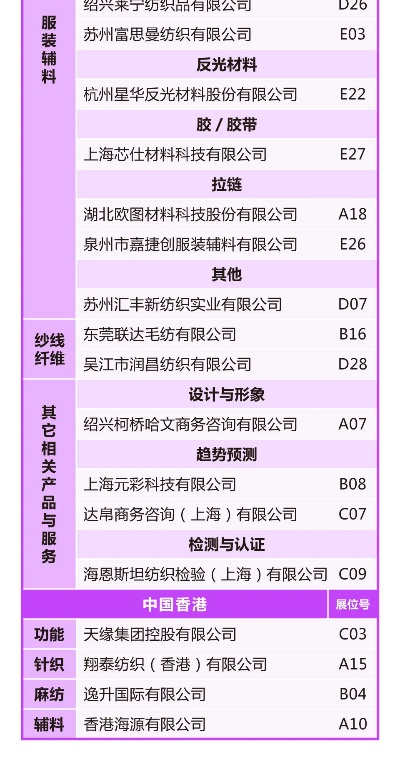

南京地区其他绿色纺织品焊接加工企业介绍

南京地区还有许多其他从事绿色纺织品焊接加工的企业,他们采用先进的设备和技术,注重环保和资源节约,取得了良好的经济效益和社会效益。

南京绿色纺织品焊接加工的技术与工艺

技术应用

南京地区在绿色纺织品焊接加工中广泛应用了先进的技术和工艺,采用高频焊接技术、环保材料等,这些技术的应用不仅提高了生产效率,也提高了产品质量和性能。

工艺流程

南京绿色纺织品焊接加工的工艺流程主要包括材料准备、焊接操作、质量检测等环节,在材料准备阶段,需要选择环保材料进行焊接加工;在焊接操作阶段,需要采用适当的焊接工艺和设备;在质量检测阶段,需要确保产品质量符合相关标准。

南京绿色纺织品焊接加工的未来展望

发展趋势

随着人们对环境保护和可持续发展的重视度不断提高,南京绿色纺织品焊接加工将继续发展壮大,该行业将更加注重环保和资源节约,提高产品质量和性能,满足消费者需求,还将加强技术研发和创新,推动行业转型升级。

挑战与对策

在南京绿色纺织品焊接加工的发展过程中,仍面临一些挑战,需要加强技术研发和创新,提高生产效率和质量;需要加强市场推广和品牌建设,提高产品知名度和竞争力;还需要加强环保意识教育,提高全社会对环境保护和可持续发展的认识和重视度,针对这些挑战,需要采取相应的对策和措施。

南京作为中国的历史文化名城,在绿色纺织品的焊接加工领域取得了显著成就,通过先进的焊接技术和工艺的应用,以及注重环保和资源节约的理念,南京地区的绿色纺织品焊接加工行业将继续发展壮大,该行业也将面临更多的机遇和挑战,我们需要加强技术研发和创新,提高生产效率和质量;加强市场推广和品牌建设;加强环保意识教育;推动行业转型升级。

Articles related to the knowledge points of this article:

The Location of Shanghai Textile Wholesale Market

A Comprehensive Guide to Japanese Textile Brands

A Comprehensive Guide to Textile Inspection Standards for Quality Control