The Essentials of Textile Chemical Performance Testing Standards

The Essentials of Textile Chemical Performance Testing Standards,Textile chemical performance testing is an essential aspect of textile quality control. The standards for this testing are designed to ensure that textile products meet the required performance standards, including strength, durability, and safety. These standards provide a framework for evaluating the chemical properties of textile materials, such as fibers and fabrics, and their potential impact on human health and the environment.,The standards define the methods and procedures for conducting chemical performance testing, including the selection of appropriate test methods and the preparation of samples for testing. They also specify the criteria for evaluating the results of the tests, including the determination of the minimum requirements for specific performance characteristics.,Overall, the essentials of textile chemical performance testing standards provide a comprehensive guide for textile manufacturers and users to ensure that their products meet industry-accepted standards for chemical performance. By following these standards, textile manufacturers can improve the quality and safety of their products while reducing the risk of harm to consumers and the environment.

Introduction: Textiles are an integral part of our daily lives, from clothing to bedding and even upholstery. They play a crucial role in providing comfort, functionality, and aesthetic appeal. However, the chemical properties of textiles can vary significantly depending on their intended use, manufacturing processes, and end-user requirements. As such, it is essential for manufacturers and consumers alike to ensure that textile products meet certain chemical performance standards. In this article, we will explore some of the most critical textile chemical performance testing standards and provide an overview of how they are typically applied.

Chemical Resistance Tests: One of the most important aspects of textile chemical performance is its resistance to various chemicals and solvents. This includes tests for water resistance, oil resistance, and stain resistance. For example, a water resistance test measures how well a textile material can resist being soaked in water before it becomes damaged or loses its shape. Similarly, an oil resistance test evaluates how well a textile material can resist being coated with oil before it becomes stained or damaged. Stain resistance tests involve exposing a textile sample to a known stain solution and measuring its color change after exposure.

Colorfastness Tests: Colorfastness is another critical aspect of textile chemical performance. It refers to the ability of a textile material to maintain its color appearance over time, even when exposed to light, heat, and other environmental factors. Colorfastness tests are performed using a standardized color chart and a spectrophotometer to measure the degree of color change. Common colorfastness tests include fastness to light (ISO 105-C04), fastness to washing (ISO 105-B04), and fastness to perspiration (ISO 105-A02).

Moisture Absorption and Rheology Tests: Moisture absorption is another important factor in textile chemical performance. It refers to the amount of water that a textile material can absorb when wet. Moisture absorption tests are performed by measuring the weight gain of a textile sample after being weighed dry and then weighed again after being soaked in water for a specified period. Rheology tests evaluate the flow properties of textile materials, such as viscosity and elasticity, which can affect their performance in specific applications.

Biodegradability Tests: As concerns about environmental sustainability continue to grow, biodegradability has become an increasingly important factor in textile chemical performance. Biodegradability tests measure how quickly a textile material decomposes when exposed to soil and other environmental conditions. These tests are typically conducted using accelerated aging methods, such as salt spray testing or composting testing, to simulate natural degradation processes.

Case Study: Consider the case of a high-end fashion brand that produces luxury fabrics for their clothing line. To ensure that their products meet the highest standards of chemical performance, they conduct a comprehensive range of tests, including moisture absorption, colorfastness, and biodegradability. By following these standards, they can confidently claim that their fabrics are not only visually appealing but also environmentally responsible.

Conclusion: In conclusion, textile chemical performance testing standards play a vital role in ensuring that textile products meet the needs of both manufacturers and consumers. Whether it's evaluating resistance to chemicals and solvents, maintaining color and texture over time, or assessing biodegradability, these standards help to create a safer and more sustainable textile industry. By following these standards, textile manufacturers can build trust with customers and contribute to a greener future.

纺织品作为日常生活中不可或缺的衣被材料,其质量直接关系到人们的舒适度和健康,为了确保纺织品在各种环境条件下都能保持良好的性能,制定并执行严格的化学性能测试标准至关重要,本篇文章将详细介绍纺织品化学性能测试的标准以及相关案例。

纺织品化学性能测试标准概述

测试目的

纺织品化学性能测试旨在评估纺织品的耐水性、耐酸性、耐碱性、抗紫外线性能等,以确保其在各种环境条件下都能满足使用要求。

测试方法与参数

(1)耐水性测试:通过模拟日常生活中的洗涤条件,观察纺织品在特定时间内的吸水性、抗洗色性能等。 (2)耐酸性测试:使用酸性溶液模拟纺织品在使用过程中可能遇到的酸雨等环境条件。 (3)耐碱性测试:通过模拟日常生活中的洗涤条件,观察纺织品在特定时间内的抗碱性变化。 (4)抗紫外线性能测试:通过仪器测试纺织品对紫外线的抵抗能力,评估其在户外环境中的使用寿命。

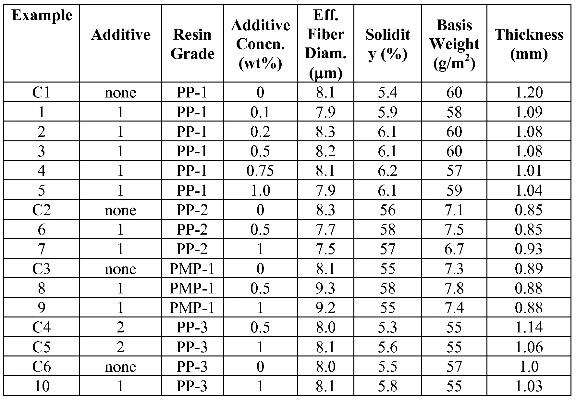

测试标准表格

以下是纺织品化学性能测试标准的表格示例:

| 测试项目 | 测试方法 | 参数要求 | 示例标准 |

|---|---|---|---|

| 耐水性 | 模拟日常洗涤条件 | 时间、吸水性、抗洗色性能等 | 至少持续3小时,符合相关行业标准 |

| 耐酸性 | 使用酸性溶液模拟 | pH值、吸湿性变化等 | 符合相关行业标准或国家相关标准 |

| 耐碱性 | 模拟日常洗涤条件 | 时间、抗碱性变化等 | 符合相关行业标准或国家相关标准 |

| 抗紫外线性能 | 仪器测试 | 紫外线照射时间、颜色变化等 | 符合相关行业标准或国家相关标准 |

案例分析

纺织品化学性能测试案例一:某品牌丝绸面料

某品牌丝绸面料在市场上广受欢迎,为了确保其质量,对其进行了全面的化学性能测试,该案例中,采用了耐水性、耐酸性等标准进行测试,具体操作如下:

(1)耐水性测试:在模拟洗涤条件下,该面料能够保持较好的吸水性和抗洗色性能,符合行业标准要求。 (2)案例分析:该品牌丝绸面料在市场上具有较高的声誉和口碑,证明其具有良好的化学性能和耐用性。

纺织品化学性能测试案例二:某户外运动用品公司生产的高档防水布料

某户外运动用品公司生产的高档防水布料,为了满足户外环境的使用要求,对其进行了严格的化学性能测试,该案例中,主要关注其耐碱性性能,具体操作如下:

(1)耐碱性测试:该防水布料经过长时间的模拟户外环境使用后,仍能保持良好的抗碱性,符合户外环境的使用要求。 (2)案例分析:该防水布料在户外环境下表现出色,适用于各种恶劣天气条件,得到了消费者的广泛认可。

纺织品化学性能测试是确保纺织品质量的重要手段,通过制定并执行严格的化学性能测试标准,可以确保纺织品在各种环境条件下都能保持良好的性能,在实际应用中,应结合具体情况选择合适的测试方法,并严格按照标准进行操作,还应注重案例分析,以便更好地了解纺织品化学性能测试的实际效果和应用价值。

Articles related to the knowledge points of this article:

Textile Manufacturing Process Overview

The Scope of Textile Design in a Professional Focus

Unlocking the Benefits of EPR Compliance for French Textile Exporters