Crafting the Perfect Textile:A Guide to Detailed Fabrication Processes

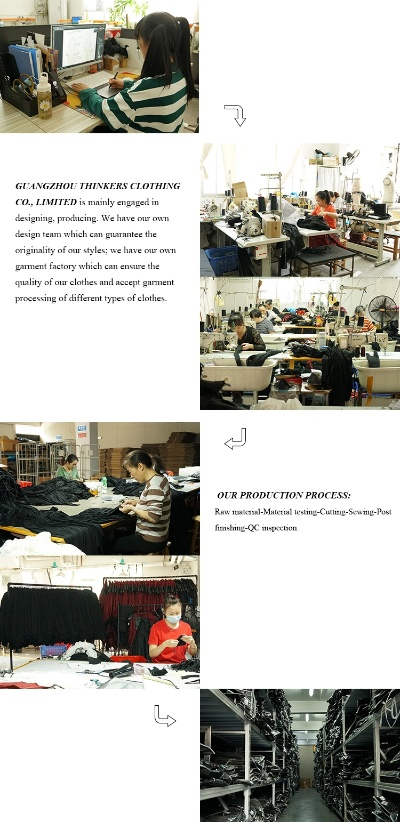

"Crafting the Perfect Textile: A Guide to Detailed Fabrication Processes",This comprehensive guide provides a thorough understanding of the fabrication process, from raw materials to finished products. The guide covers various techniques used in textile manufacturing, including weaving, knitting, and embroidery. It also discusses the importance of quality control and inspection during the production process.,The guide emphasizes the need for precision and attention to detail in all stages of the fabrication process. This includes selecting appropriate materials, designing patterns, and following proper procedures for stitching and finishing.,By following this guide, readers can gain a deeper understanding of the textile industry and become more confident in their ability to produce high-quality products. It is an essential resource for anyone interested in learning about the complexities of textile manufacturing and how to achieve excellence in their work.

Introduction: In the world of textiles, every stitch counts. From the initial design concept to the final product, every step in the fabrication process plays a crucial role in determining the quality and end result of a textile piece. In this guide, we will explore the various stages involved in the textile manufacturing process, from raw material procurement to finished product assembly. By understanding these stages, you can gain a deeper appreciation for the complexities and precision required in the textile industry.

Material Sources: The success of any textile project begins with the selection of high-quality materials. Raw materials such as cotton, polyester, and wool are sourced from reliable suppliers who adhere to strict environmental and ethical standards. These materials are then processed into fibers or yarns, which are used to create fabrics. The choice of raw materials significantly impacts the final product's texture, color, and durability. For example, using natural fibers like cotton and linen ensures softness and breathability, while synthetic materials like polyester provide strength and resistance to wear and tear.

Design Concept: Once the raw materials have been selected, the next step is to develop a design concept that meets the specific requirements of the project. This may involve sketches, CAD drawings, or even 3D modeling software. The design must be carefully considered to ensure it is both aesthetically pleasing and functional. It is essential to consider factors such as color coordination, pattern consistency, and fit for the intended use. Designers must also take into account the manufacturing process and the limitations of the chosen materials. For instance, a garment designer might choose a looser weave to accommodate for a larger range of body sizes.

Pattern Making: Once the design is finalized, pattern making becomes critical. This involves creating detailed instructions for the production of each individual piece. Pattern makers use specialized tools and techniques to accurately replicate the design on the fabric. The accuracy of the pattern directly affects the quality of the final product, so it requires meticulous attention to detail. For example, a small error in the pattern can lead to a mismatched seam or uneven draping, resulting in a poorly fitting garment.

Cutting and Weaving: Once the pattern has been made, it is time to cut the fabric into pieces and weave them together. This process involves precise measurements and alignment to ensure that the pieces fit together seamlessly. The weavers use specialized tools such as looms or knitting machines to create intricate patterns on the fabric. The quality of the weaving process can greatly affect the overall appearance and durability of the fabric. For example, using advanced techniques like twill weaving or zigzag weaving can add texture and depth to the fabric, making it more visually appealing and durable.

Quality Control: Quality control is essential in ensuring that the textile products meet the desired standards. This involves rigorous inspections of the fabric for defects such as fraying, pilling, or color variations. Additionally, testing methods like washing and drying cycles, shrinkage rates, and wear tests are conducted to evaluate the fabric's performance under different conditions. Quality control measures help to minimize errors and ensure that the end product meets customer expectations. For instance, a garment manufacturer might conduct a durability test on its fabric before mass production to prevent defects during shipping.

Packaging and Shipping: Once the textile products are ready for shipment, careful packaging is necessary to protect them during transit. This includes using sturdy boxes, bubble wrap, and other protective materials to prevent damage during transport. The shipping method also plays a crucial role in ensuring that the products arrive safely and intact. For example, high-end fashion brands might opt for express delivery services to ensure that their garments reach customers quickly and without damage.

Conclusion: The textile manufacturing process is a complex and multifaceted endeavor that requires expertise in design, pattern making, cutting, weaving, quality control, and packaging. By following these guidelines, manufacturers can produce high-quality textile products that meet the needs and expectations of their customers. As the saying goes, "A well-made garment is not just a garment; it is an art form." And in the textile industry, every stitch counts.

随着纺织行业的快速发展,纺织品加工环节的重要性日益凸显,本报告旨在详细阐述纺织品加工的详情,包括工艺流程、设备配置、质量控制等方面,以便更好地满足市场需求。

工艺流程

原料准备

原料采购:我们选用优质棉纤维作为主要原料,确保产品质量。

清洗处理:采用先进的清洗设备,去除杂质和残留物。

预处理:根据织物类型和工艺要求进行预处理,如染色、印花等。

织造工艺

织造设备:采用先进的织机设备,如梭织机、针织机等。

织造流程:根据设计图纸和客户要求进行织造,包括织造密度、花纹设计等。

印染工艺

印染设备:采用先进的印染设备,如染缸、烘干设备等。

印染流程:根据织物颜色和客户要求进行印染,确保颜色鲜艳、质地均匀。

设备配置

纺织机械

纺织机械品牌:我们主要使用XX品牌纺织机械,具有高效、稳定的特点。

主要设备参数:如梭织机的最大产量、针织机的编织速度等。

印染设备

印染设备品牌:我们使用的印染设备均经过严格筛选和质量检测,确保产品质量。

主要设备参数:如染缸的容量、烘干设备的温度控制等。

质量控制

质量检测标准

质量检测标准主要包括纤维含量、织物密度、颜色鲜艳度等指标,我们采用专业的质量检测仪器和方法,确保产品质量符合国家标准。

质量管理体系

我们建立了一套完善的质量管理体系,包括原材料采购、生产过程控制、成品检验等环节,我们还定期对生产过程进行监督和检查,确保产品质量稳定。

案例说明

以某纺织品加工企业为例,详细阐述其纺织品加工详情,该企业采用先进的纺织机械和印染设备,严格控制产品质量,确保产品符合市场需求,具体细节如下:

- 原料采购:该企业采购优质棉纤维作为主要原料,同时严格控制原料质量,确保产品质量符合国家标准。

- 织造工艺:该企业采用先进的织造工艺,根据设计图纸和客户要求进行织造,确保织物质量符合客户要求,该企业还注重环保和节能,采用环保型设备和工艺。

- 印染工艺:该企业使用的印染设备均经过严格筛选和质量检测,确保产品质量符合客户要求,该企业还注重印染工艺的创新和优化,提高印染效率和产品质量。

- 实际效果:经过该企业的纺织品加工,产品质量稳定,深受客户好评,该企业的生产效率和产品质量也得到了显著提高。

总结与展望

本报告详细阐述了纺织品加工的详情,包括工艺流程、设备配置、质量控制等方面,我们还通过一个案例说明纺织品加工的细节情况,随着纺织行业的不断发展,纺织品加工将更加注重环保和节能,提高生产效率和产品质量,纺织品加工企业也将更加注重技术创新和优化,提高产品的附加值和市场竞争力。

Articles related to the knowledge points of this article:

The Fabric of Growth:An Insight into Ningbos Textile Industry

The Unique Sicheng Guo League Textile Wholesale Market

Lament Fabrics:The Art of Crafting Dreamy Textiles

Exploring the World of Textiles:A Journey Through Tide Happy Garment Trading