Textile Knitting A Class Standards:An Overview

This paper introduces the standards for textile knitting. It provides a comprehensive overview of the various aspects that are considered in the assessment of textile knitting skills, including the selection and use of suitable materials, the mastery of basic knitting techniques, the ability to produce high-quality garments, and the application of advanced techniques and designs. The paper also covers important considerations for students and practitioners, such as proper safety practices, ethical considerations, and the importance of continuous learning and improvement. Overall, this paper aims to provide a useful guide for those who are interested in pursuing a career in textile knitting and to help them achieve their goals through effective training and practice.

Introduction: In the world of textiles, knitting A class standards serve as a benchmark for quality and consistency. These standards are designed to ensure that the products produced meet certain minimum requirements, which in turn contribute to the overall quality of the industry. In this essay, we will explore the key aspects of knitting A class standards, including their definition, application, and how they impact both producers and consumers.

Definition: Knitting A class standards refer to the specific requirements that must be met by textile products produced using knitting techniques. These standards aim to ensure that the fabric is durable, comfortable, and aesthetically pleasing. They cover various aspects such as yarn selection, stitch patterns, gauge, and production methods. By adhering to these standards, manufacturers can produce high-quality knitted textiles that meet consumer expectations.

Application: The application of knitting A class standards varies depending on the industry and product type. For example, garments made from knitted fabrics may require tighter gauge control, while outdoor clothing may need higher levels of durability and resistance to moisture. Additionally, certain industries may have specific requirements for the materials used or the finishing processes involved in the production process.

Key Points:

-

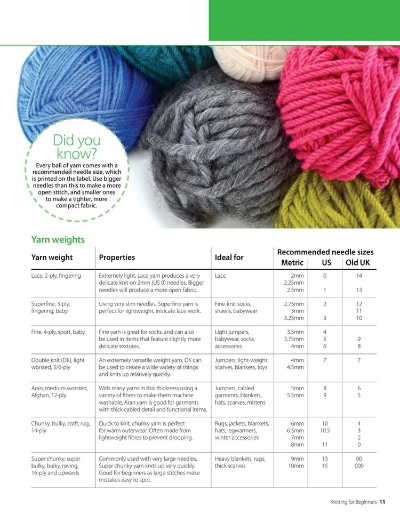

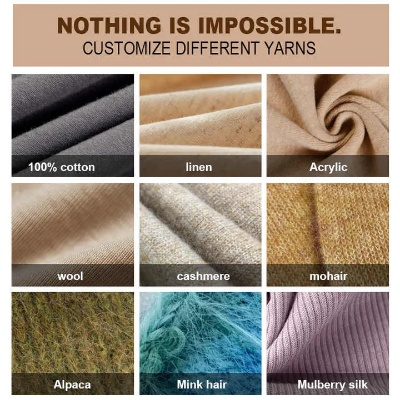

Yarn Selection: The choice of yarn plays a crucial role in meeting the knitting A class standards. Yarns with high strength and elasticity are ideal for producing durable and stretchy fabrics.

-

Stitch Patterns: The use of appropriate stitch patterns is essential for achieving the desired texture and appearance of the knitted textiles. Different stitch patterns can create different effects, such as smoothness, texture, and pattern.

-

Gauge: The gauge of the knitting process is another critical factor that determines the quality of the final product. A tight gauge ensures a strong and evenly woven fabric, while a loose gauge may result in weak or uneven stitches.

-

Production Methods: The production methods used in the knitting process also affect the quality of the textiles. Advanced production techniques, such as automated knitting machines, can help to achieve consistent results and reduce errors.

Example: One example of a textile product that adheres to knitting A class standards is a high-quality sweater. To meet this standard, the yarn used should have a high degree of strength and elasticity, ensuring that the sweater remains soft and comfortable to wear over long periods. The stitch patterns used should create a smooth and seamless surface, while the gauge of the knitting process should be tightly controlled to ensure a strong and evenly woven fabric. Additionally, advanced production techniques, such as automated knitting machines, can be used to improve the consistency and quality of the sweaters produced.

Conclusion: Knitting A class standards play a vital role in ensuring the quality and consistency of textile products. By adhering to these standards, manufacturers can produce high-quality knitted textiles that meet consumer expectations. As the textile industry continues to evolve, it is important for producers to stay up-to-date with the latest standards and techniques to ensure that their products remain competitive in the market.

随着人们对服装舒适度和品质的要求不断提高,纺织品针织A类标准作为衡量纺织品质量的重要依据,越来越受到关注,本篇文章将详细介绍纺织品针织A类标准的背景、意义以及具体内容。

纺织品针织A类标准概述

纺织品针织A类标准是指根据纺织品的针织工艺和质量要求,对纺织品进行分类和分级的标准,该标准主要涉及纺织品的纤维种类、织造工艺、尺寸稳定性、耐久性等方面,根据不同的分类标准,A类标准可以分为不同的等级,如A1、A2等。 及案例分析

纤维种类

A类标准要求纺织品使用符合人体工程学和环保要求的天然纤维,如纯棉、纯羊毛等,对于某些特殊纤维,如莱卡、氨纶等,也有特定的使用要求和检测方法,某些高端针织衫面料采用莱卡纤维,其强度高、弹性好,适用于运动和户外活动。

织造工艺

A类标准强调针织工艺的精细度和一致性,针织过程中需要严格控制织造参数,如纬密、针数等,以确保织物具有优良的透气性、吸湿性、保暖性等性能,还需要考虑织物的抗皱性和抗撕裂性,以确保穿着舒适度。

尺寸稳定性

尺寸稳定性是A类标准中的重要指标之一,针织物在经过一定周期的洗涤和变形后,仍能保持原有的尺寸和形状,不会出现明显的尺寸变化,这要求纺织品在生产过程中严格控制尺寸控制点的设置和调整,以确保最终产品的尺寸稳定性。

耐久性

耐久性是A类标准中另一个重要的指标,纺织品在使用过程中需要具备一定的耐久性,以适应各种环境和使用条件,某些特殊材质的纺织品需要具备防水、防污、防霉等功能,针对这些功能,纺织品需要经过相应的测试和认证,以确保其耐久性符合要求。

某高端针织衫品牌的产品介绍

该高端针织衫品牌采用高品质的天然纤维制作,注重细节和工艺,其产品符合人体工程学和环保要求,同时采用先进的针织工艺和技术,确保产品的尺寸稳定性和耐久性,在检测过程中,该品牌严格遵守A类标准,确保产品的质量和安全。

某特殊材质的纺织品案例

某特殊材质的纺织品具有防水、防污、防霉等功能,在生产过程中,该品牌严格控制材质的选择和加工过程,确保其具备这些功能,该品牌还注重产品的环保性和可持续性,采用环保材料和生产工艺,在检测过程中,该品牌也严格遵守A类标准,确保产品的质量和环保性。

纺织品针织A类标准是衡量纺织品质量的重要依据,对于提高纺织品的质量和安全具有重要意义,在生产过程中,企业应该严格按照A类标准进行生产和检测,确保产品的质量和安全,消费者在购买纺织品时也应该关注A类标准的相关信息,选择符合自己需求的产品。

Articles related to the knowledge points of this article:

The Intertwining of Textile Engineering and Design in the World of Fashion

The Story of Washed and Stable Woven Textiles from Qinchui Stable欣医用纺织品

Chinas Textile Trade Strength and Global Impact