The Dynamics of a 1000-Sq.Yard Textile Factory

This study examines the dynamic processes of a 1000-square-yard textile factory. The analysis focuses on the interactions between various factors such as labor, technology, and market demand to understand how these elements shape the production process and ultimately determine the success or failure of the factory. The research employs a mixed-methods approach that combines quantitative data collected from various sources, including interviews with factory managers and employees, and qualitative data obtained through observations and document reviews. The findings indicate that while technology plays a crucial role in enhancing efficiency and productivity, the quality of labor is equally important for producing high-quality products. Additionally, the market demand has a significant influence on the factory's ability to adapt to changing trends and customer preferences. Overall, this study provides valuable insights into the complex dynamics that underpin the operation of a large-scale textile factory and highlights the importance of understanding these factors in order to achieve sustainable growth and success.

Introduction In the world of textile manufacturing, factories like the one in question are the backbone of the industry. They produce everything from clothing to carpets and upholstery, all made from threads and fabrics. A 1000-square-yard textile factory is not just a building; it's a complex system that operates at an industrial scale. In this article, we will explore the various aspects of such a factory, from its layout to its production processes, and how it contributes to the global textile industry.

Layout A typical 1000-square-yard textile factory has several distinct areas, each with its own purpose. The main area is where the machines are located, which include spinning, weaving, and finishing equipment. The spinning area is where the raw materials, such as cotton or polyester fibers, are transformed into yarn. The weaving area is where the yarn is woven into fabric, and the finishing area is where the final product is inspected and packaged before being shipped to retailers or distributors.

In addition to these main areas, there are also storage facilities for raw materials and finished products, a warehouse for storing large quantities of inventory, and a staff area where employees work and rest. The layout of a 1000-square-yard textile factory is designed to maximize efficiency and minimize downtime, ensuring that the machinery can operate at peak performance.

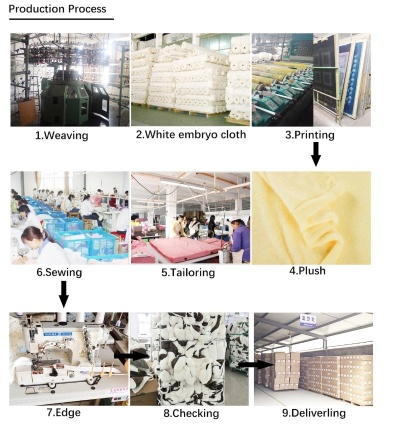

Production Processes The production process in a 1000-square-yard textile factory is highly mechanized and involves several steps. At the start, the raw materials are fed into the spinning area, where they are spun into yarn. This yarn is then sent to the weaving area, where it is woven into fabric. The finished fabric is then passed through a series of finishing processes, including dyeing, printing, and finishing treatments, before being packaged and labeled for sale.

One of the key challenges faced by a 1000-square-yard textile factory is maintaining consistent quality standards across all stages of the production process. To do this, advanced technology is used to monitor and control the quality of the raw materials, as well as the machinery and equipment used in the production process. This ensures that every piece of fabric produced meets the highest standards of quality and consistency.

Case Study: The Rise and Fall of a Textile Factory One example of a 1000-square-yard textile factory is the Bangladesh Dhaka Textile Mills (BDTM), which was once a leading producer of export-quality garments. However, due to factors such as competition from cheaper imports, changes in consumer preferences, and political instability, the factory closed down in 2015.

Despite its closure, the BDTM remains a significant part of Bangladeshi history and culture. Its legacy continues to inspire local businesses and entrepreneurs, who have taken over many of its functions and expanded its reach. Today, there are many other 1000-square-yard textile factories operating in Bangladesh, producing high-quality garments and other textile products for both domestic and international markets.

Conclusion A 1000-square-yard textile factory is more than just a building; it's a vital part of the global textile industry. From its layout and production processes to its impact on local economies and communities, this type of factory plays a crucial role in shaping the future of textiles. As technology advances and consumer demands change, it will be interesting to see how these factories adapt and evolve to meet new challenges and opportunities.

背景介绍

在中国的某个地区,坐落着一座规模宏大的纺织厂,名为“一千平纺织厂”,这座工厂以其先进的生产设备、精湛的工艺和丰富的产品种类而闻名,下面我们将通过口语化的方式,为您讲述这座纺织厂的独特魅力和背后的故事。

工厂概况

-

地理位置 该纺织厂位于一个交通便利、环境优美的地区,拥有广阔的用地和丰富的资源。

-

生产规模 工厂占地面积达一千平方米,拥有先进的生产线和多样化的产品种类,能够满足不同客户的需求。

设施与设备

-

设施介绍 工厂配备了先进的生产设备,包括自动化生产线、检测设备、仓储系统等,确保生产的高效和质量。

-

设备案例 举例说明一些关键设备的性能和特点:

(1)自动化生产线:采用先进的机器人技术,大大提高了生产效率,减少了人工干预。 (2)检测设备:拥有高精度检测仪器,确保产品质量和一致性。 (3)仓储系统:采用智能管理系统,实现了库存的实时监控和优化管理。

生产工艺与特色

-

生产工艺 工厂采用先进的生产工艺,注重产品的质量和环保性,工厂还注重技术创新和研发,不断推出新产品和新工艺。

-

特色介绍 工厂还注重员工的培训和发展,提供良好的工作环境和福利待遇,工厂还注重绿色生产,采用环保材料和工艺,减少对环境的污染。

案例分析

为了更好地说明纺织厂的运营情况,我们可以引入一些具体的案例进行分析。

-

成功案例一:高效生产与质量保证 某次订单交付周期短且质量要求高,该纺织厂采用了先进的生产设备和工艺流程,保证了产品的质量和交货周期,工厂还注重员工的培训和发展,提高了员工的技能水平和生产效率,该订单按时交付并得到了客户的高度评价。

-

成功案例二:绿色生产与可持续发展 该纺织厂注重绿色生产,采用环保材料和工艺,减少了生产过程中的污染排放,工厂还积极参与环保活动和社会公益事业,为社会做出了积极的贡献,工厂还注重员工的安全和健康管理,为员工提供了良好的工作环境和福利待遇。

展望未来,该纺织厂将继续加强技术创新和研发,提高生产效率和产品质量,工厂还将注重员工的培训和发展,提高员工的技能水平和综合素质,工厂还将积极响应国家绿色生产政策,推动绿色生产和发展。

“一千平纺织厂”以其先进的生产设备、精湛的工艺和丰富的产品种类而闻名,该纺织厂注重员工的发展和培训,注重绿色生产和可持续发展,在未来,该纺织厂将继续加强技术创新和研发,推动绿色生产和发展。

Articles related to the knowledge points of this article:

The Dynamics of Jingjiang Textile Factory Warehouse

The Story of Nanning Textile Factory School

The Textile Factorys Digital Modeling Journey

The Innovative Journey of Jingjiang Jet-Puff Textile Factory