Organizing Your Textile Material Warehouse Like a Pro

Organizing your textile material warehouse like a pro is essential for ensuring efficient and effective management of inventory. Here are some tips to help you achieve this:,1. Establish clear organizational systems: Develop a system that allows for easy tracking of materials, such as by color, type, or size. This will help you quickly locate the materials you need when needed.,2. Use technology: Consider investing in software or hardware that can automate certain processes, such as tracking inventory, managing orders, and generating reports. This will save time and reduce errors.,3. Maintain accurate records: Keep accurate records of all transactions, including purchase orders, invoices, and returns. This will help you stay on top of your inventory and avoid overstocking or understocking.,4. Train employees: Ensure that all employees understand the importance of maintaining accurate records and following proper procedures for handling materials. This will ensure that everyone is working together to keep your warehouse organized.,By following these tips, you can create a well-organized textile material warehouse that is both efficient and cost-effective.

Introduction: When it comes to textile production, the efficiency and accuracy of your warehouse play a crucial role in ensuring that your products are always ready for shipment on time. That's why organizing your textile material warehouse is so important. In this guide, we'll explore some best practices for organizing your textile material warehouse, including how to create an inventory system, sorting materials, and maintaining order.

Inventory System: The first step in organizing your textile material warehouse is to establish an effective inventory system. This involves creating a detailed list of all the materials stored in the warehouse, along with their quantities and any relevant information such as supplier details or purchase orders. To keep track of these items, you can use a spreadsheet or a specialized inventory management software.

Example: For instance, if you work at a textile mill, you might have different categories of materials such as yarn, fabric, and accessories. You can create separate columns for each category, along with subcategories within each category. This way, you can easily identify which materials are in stock and which need to be ordered.

Sorting Materials: Once you have an inventory system in place, the next step is to sort your materials based on their type, size, color, and other relevant criteria. This will help you quickly locate the materials you need when making decisions about production or inventory management.

Example: If you have a large inventory of fabric samples, you might want to categorize them by color and then by pattern or design. This way, you can quickly find the fabric you need for a particular project without having to sift through all the samples.

Maintaining Order: Finally, once you have organized your materials and sorted them according to their needs, it's important to maintain order throughout the warehouse. This means regularly checking inventories, restocking materials as needed, and removing obsolete or damaged items.

Example: To maintain order, you can set up regular inspections of your materials to check for damage or wear and tear. You can also consider implementing a rotation system for materials storage, rotating them from one area to another to minimize damage and improve organization.

Conclusion: Organizing your textile material warehouse is essential for ensuring efficient production and accurate inventory management. By establishing an effective inventory system, sorting materials based on type and size, and maintaining order through regular checks and rotation systems, you can streamline your operations and reduce waste. So, take the time to organize your textile material warehouse today and see the difference it can make for your business!

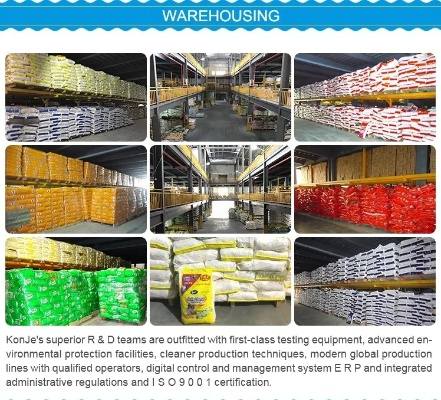

纺织品原料仓库规整图片

图片说明:

展示的是一幅纺织品原料仓库的布局图,主要展示了仓库内的各种纺织品原料分类摆放,包括各种布料、纤维、纱线等,每个原料都有清晰的标识牌,便于查找和管理。

英文口语化内容:

以下是对纺织品原料仓库规整图片的详细描述:

原料分类与摆放

- 布料区:各种棉、麻、丝绸等天然纤维的布料整齐摆放,有明确的标识牌区分不同种类。

- 纤维区:各种合成纤维、再生纤维等各类纤维原料分类摆放,便于查找和管理。

- 纱线区:各种纱线按照种类和用途分类摆放,便于采购和存储。

- 包装材料区:用于存放包装袋、纸箱等辅助材料,保持整洁。

案例分析

为了更好地说明这一规整管理,我们可以引入一个具体的英文案例。

高效管理

在某大型纺织品原料仓库中,采用了先进的自动化设备进行原料的分类和摆放,仓库管理员通过一张清晰的布局图,将原料按照种类和用途进行分类存放,仓库配备了先进的监控系统,实时监控仓库内的环境状况,确保仓库的整洁和高效运营,仓库还设立了专门的采购和存储部门,负责原料的采购和存储工作,大大提高了仓库的管理效率和运营水平。

细节补充说明

- 布料区:每个布料都有明确的标识牌,包括颜色、材质等信息,方便查找和管理,仓库还配备了温度湿度监测设备,确保布料存放环境的适宜性。

- 纤维区:各种纤维原料都采用了专门的存储容器进行存放,容器内部设有防尘、防潮、防虫等措施,确保原料的存放安全性和有效性。

- 纱线区:纱线按照种类和用途进行了分区存放,不同种类的纱线都有专门的存放区域,便于采购和存储,仓库还配备了先进的称重设备,实时监控纱线的库存情况。

- 包装材料区:存放了各种包装袋、纸箱等辅助材料,这些材料都经过严格的检查和清洁处理,确保其质量和安全性,仓库还设立了专门的废品回收区,对过期或损坏的包装材料进行回收和处理。

通过这一纺织品原料仓库规整图片,我们可以看到,一个规范的纺织品原料仓库应该具备清晰的布局图、先进的设备和技术、完善的规章制度等要素,在实际操作中,还需要注重细节管理、提高员工素质、加强安全防范等方面的工作,才能确保纺织品原料仓库的整洁和高效运营,为企业的生产和销售提供有力支持。

Articles related to the knowledge points of this article:

Springdale Textiles:A Journey into the World of Fabric and Fashion

Textile Factory Emergency Response Card

Hainans Textile Industry Boosts Promotion with Price Incentives