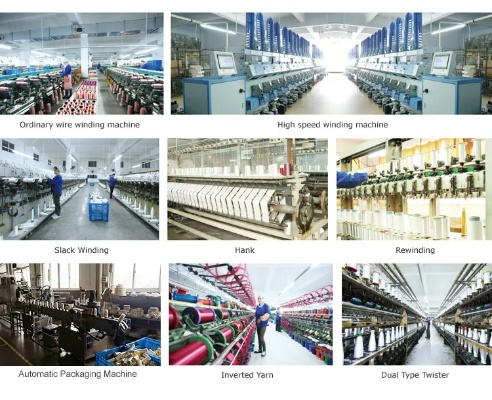

The Role of Textile Testing in Quality Control in Wuxi,China

Textile testing is a crucial aspect of quality control in Wuxi, China. This process involves inspecting the fabric for various properties such as color, texture, and durability. The results of these tests are used to determine whether the product meets industry standards and consumer expectations. Additionally, textile testing helps identify any defects or issues that may arise during production, allowing manufacturers to take corrective action before the product reaches the market. Overall, textile testing plays an essential role in ensuring that the products produced in Wuxi meet high standards of quality and safety.

In the vibrant city of Wuxi, located in eastern Jiangsu province, textile testing plays a crucial role in ensuring the quality and safety of consumer goods. This industry is known for its advanced production techniques and innovative designs, which have made it one of the leading producers of high-quality textiles in China. However, to maintain this reputation, it is essential that every product undergoes rigorous testing before being released into the market. In this essay, we will explore the importance of textile testing in Wuxi and how it contributes to the overall quality control process.

Textile testing is a comprehensive process that involves various stages, each aimed at identifying potential flaws or defects in the fabric. The first stage is sampling, where small samples of the fabric are taken for inspection. These samples are then sent to a laboratory for analysis. The second stage is pretreatment, where the sample is subjected to various treatments to remove any impurities or residues that may interfere with the testing process. Once the sample is ready, it is analyzed using various methods such as visual inspection, mechanical tests, and chemical analysis.

Visual inspection is the most common method used for textile testing. It involves examining the surface of the fabric for any visible defects such as holes, tears, or wrinkles. Mechanical tests involve measuring the strength and flexibility of the fabric, while chemical analysis checks for any harmful substances present in the fabric. Each stage of testing helps to identify specific issues that need to be addressed before the product can be released to the market.

One example of a textile product that underwent extensive testing in Wuxi is a brand of clothing. The company was aware of the importance of quality control and decided to invest in advanced testing facilities. The company's team worked closely with experts from the local government and industry associations to develop a comprehensive testing program. The plan included both manual and automated testing methods, ensuring that all aspects of the product were thoroughly examined.

The testing process involved several stages, including pre-production testing, production testing, and post-production testing. During pre-production testing, the fabric was carefully inspected for any defects or irregularities. Production testing involved testing the fabric under different conditions to ensure that it met the required standards. Post-production testing focused on analyzing the final product to ensure that it met all regulatory requirements.

The results of the testing were critical in determining whether the product passed or failed. If any issues were found during testing, the company had to take corrective measures to address them before releasing the product to the market. This approach not only improved the overall quality of the products but also helped to build trust with consumers by demonstrating that the company was committed to producing high-quality products.

Another example of a textile product that underwent rigorous testing in Wuxi is a line of home furnishings. The company was aware of the importance of quality control and decided to invest in advanced testing facilities. The company's team worked closely with experts from the local government and industry associations to develop a comprehensive testing program. The plan included both manual and automated testing methods, ensuring that all aspects of the product were thoroughly examined.

The testing process involved several stages, including pre-production testing, production testing, and post-production testing. During pre-production testing, the fabric was carefully inspected for any defects or irregularities. Production testing involved testing the fabric under different conditions to ensure that it met the required standards. Post-production testing focused on analyzing the final product to ensure that it met all regulatory requirements.

The results of the testing were critical in determining whether the product passed or failed. If any issues were found during testing, the company had to take corrective measures to address them before releasing the product to the market. This approach not only improved the overall quality of the products but also helped to build trust with consumers by demonstrating that the company was committed to producing high-quality products.

In conclusion, textile testing is an essential component of the quality control process in Wuxi, China. By implementing a comprehensive testing program and following strict guidelines, companies can ensure that their products meet all regulatory requirements and provide consumers with safe and high-quality products. The use of advanced technology and collaboration with industry experts has helped to improve the efficiency and accuracy of the testing process, making it an integral part of the textile industry in Wuxi.

在繁忙的纺织产业中,无锡的纺织品检测工作至关重要,我们将重点关注一位在无锡从事纺织品检测的个人,他的专业知识和经验将为读者提供有价值的信息。

个人背景与职责

-

个人背景 无锡的纺织品检测个人名叫[名字],他拥有丰富的纺织品检测经验,熟悉各种检测标准和流程,他致力于确保纺织品的质量和安全,为消费者提供可靠的产品。

-

职责 作为纺织品检测专家,[名字]的主要职责包括对进厂的纺织品进行严格的质量检测,确保符合相关标准和法规,他还会参与新产品的研发和质量控制工作,为企业的持续发展提供技术支持。

专业知识和技能

-

专业知识 [名字]精通纺织品检测的各种技术和方法,包括纤维分析、化学分析、物理性能测试等,他能够熟练操作各种检测设备和软件,确保检测结果的准确性和可靠性。

-

技能 除了专业知识外,[名字]还具备丰富的实践经验,他能够快速准确地判断纺织品的质量问题,提出有效的解决方案,他还具备良好的沟通能力和团队协作精神,能够与供应商、客户和其他部门进行有效沟通。

案例分析

以无锡某纺织企业为例,展示[名字]的专业能力和实践经验,该企业主要生产各种类型的纺织品,包括床上用品、服装等,在纺织品检测过程中,[名字]发现了一些质量问题,如某些纤维含量不符合标准、面料手感不佳等,针对这些问题,[名字]提出了有效的解决方案,并协助企业进行了整改,[名字]还参与了新产品的研发和质量控制工作,为企业提供了技术支持和指导。

个人经验和贡献

-

个人经验 在无锡的纺织品检测工作中,[名字]积累了丰富的经验,他能够快速准确地判断纺织品的质量问题,提出有效的解决方案,[名字]还注重提高自己的检测技能和知识水平,不断学习和掌握新的技术和方法,他的专业知识和实践经验为无锡的纺织品检测工作提供了有力支持。

-

个人贡献 作为无锡的纺织品检测专家,[名字]在促进无锡纺织产业的发展方面做出了重要贡献,他通过严格的质量检测和有效的质量控制工作,提高了无锡纺织产品的质量和竞争力,[名字]还积极参与了新产品的研发和质量改进工作,为企业的持续发展提供了技术支持和指导,他的专业知识和实践经验为无锡的纺织产业带来了新的发展机遇和挑战。

[名字]作为无锡的纺织品检测个人,他的专业知识和实践经验为无锡的纺织产业发展提供了有力支持,他的工作质量和效率得到了广大企业和消费者的认可和好评,在未来,我们期待看到更多像[名字]这样的专业人才在无锡的纺织产业中发挥更大的作用,为无锡的纺织产业发展做出更大的贡献。

Articles related to the knowledge points of this article:

The Unique Prices of Personalized Needlework Textiles in Inner Mongolia

Textile Four Piece Set Wholesale Market Address

The Story of Xian Xintianxiang Textile Wholesale in the西安市碑林区鑫天翔纺织品批发部

The Fabric of Growth:An Insight into Ningbos Textile Industry

![The Fabric of Success:An Insight into the World of 织惠锦纺织品厂]](https://www.i505i.cn/zb_users/upload/2025/08/20250803142230175420215095821.jpg)