The Critical Steps in the Textile Pretreatment Process

The textile pretreatment process is a crucial step in the production of textile products. It involves several critical steps, such as cleaning, bleaching, dyeing, and finishing. Cleaning is the first step in the pretreatment process, which involves removing any dirt or debris from the fabric. Bleaching is then applied to remove any remaining colorants or impurities. Dyeing is the next step, where the desired color is added to the fabric using various techniques. Finally, finishing is done to enhance the appearance and durability of the fabric. By following these critical steps, textile manufacturers can produce high-quality textile products that meet the needs of consumers.

Introduction: The textile industry is a vast and complex sector that relies heavily on the quality of raw materials used in its production process. One crucial step in this process is the pretreatment of textiles, which involves various chemical and physical treatments to enhance their performance, durability, and safety. In this article, we will explore the different pretreatment techniques used in the textile industry and provide an overview of some key examples.

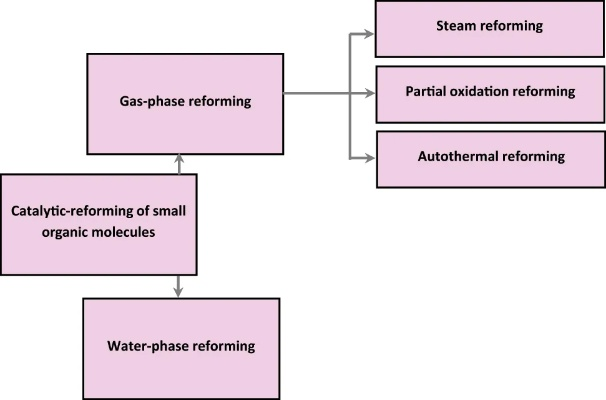

Chemical Pretreatments: Chemical pretreatments are essential for removing impurities, improving colorfastness, and enhancing the mechanical properties of textiles. Some common chemical pretreatments include:

-

Chemical Dyeing: This method involves applying a dye directly onto the fabric surface using chemicals such as alkaline solutions or enzymes. The dye is then fixed onto the fiber by heating or other treatments.

-

Chemical Fixation: This technique involves treating the fabric with a chemical solution that reacts with the fibers to form a permanent bond. This can be done by cross-linking the fibers or by creating a coating on the surface of the fabric.

-

Chemical Stabilization: This method involves treating the fabric with a chemical solution that helps to prevent shrinkage, warp, and wrinkle formation during washing and drying.

Physical Pretreatments: Physical pretreatments are used to improve the surface properties of textiles, such as wettability, friction, and wear resistance. Some common physical pretreatments include:

-

Mechanical Treating: This method involves subjecting the fabric to high pressure and heat to remove any loose fibers or impurities from the surface. This can be done using machines such as rotary brushes or drums.

-

Chemical Treating: This technique involves treating the fabric with a chemical solution that reacts with the fibers to create a more uniform surface or improve the colorfastness of the fabric.

-

Heat Treating: This method involves subjecting the fabric to high temperatures to improve its strength, flexibility, and resistance to wear and tear.

Case Study: One example of a successful textile pretreatment process is the use of chemical dyeing in the fashion industry. Companies like Zara and H&M rely on this technique to produce colorful and vibrant garments that last longer than traditional dyed fabrics. By carefully selecting the right dyes and treatment methods, these brands are able to achieve a balance between cost and quality, while still meeting the demands of consumers who demand high levels of style and sustainability.

Conclusion: The textile pretreatment process is a critical step in the production of high-quality textile products. By understanding the different types of pretreatment techniques available and how they can be applied to different types of fabrics, manufacturers can optimize their processes and meet the needs of their customers. As the textile industry continues to evolve, it is important for companies to stay up-to-date with the latest developments in pretreatment technology to ensure they remain competitive in a rapidly changing market.

在纺织品的整个生产过程中,前处理环节是一个至关重要的环节,它涉及到对纺织材料的预处理,包括清洁、整理、染色等工艺,本文将详细介绍纺织品前处理环节的相关知识,并通过英文案例说明来加深理解。

纺织品前处理环节概述

定义与作用

纺织品前处理环节主要涉及对纺织材料的清洁、整理和预处理,以提高纺织品的性能和质量,它包括一系列工艺过程,如漂白、染色、印花等,这些工艺过程旨在去除纺织材料表面的杂质、油脂、灰尘等,同时赋予纺织材料所需的颜色、质地和功能。

常见前处理环节技术

(1)化学处理:使用化学试剂对纺织材料进行清洗、整理和染色,使用酸性或碱性溶液去除杂质,使用染料进行染色。

(2)物理处理:利用物理方法去除纺织材料表面的杂质和油脂,如机械磨皮、气流烘干等。

前处理环节案例分析

某品牌纺织品的前处理过程

该品牌采用化学处理方法对纺织品进行预处理,经过清洗和整理后,纺织品表面更加光滑、洁净,同时颜色更加鲜艳,该品牌还采用了印花工艺,赋予纺织品独特的图案和纹理。

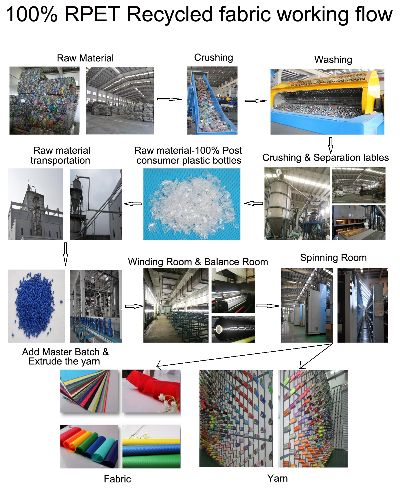

环保型纺织品的前处理过程

近年来,环保型纺织品越来越受到市场的青睐,一些企业采用生物酶处理方法对纺织品进行前处理,不仅提高了纺织品的性能和质量,还降低了对环境的污染,该方法利用生物酶的天然特性,对纺织材料进行清洁和整理,同时不会产生有害物质。

纺织品前处理环节的技术细节与操作要点

技术细节

(1)化学处理:使用适当的化学试剂和工艺条件进行清洗和整理,在清洗过程中,要注意控制温度、时间等参数,以避免过度清洗或残留物质对纺织材料造成损害,在整理过程中,要注意选择合适的整理剂和工艺条件,以达到理想的整理效果。

(2)物理处理:利用机械磨皮、气流烘干等物理方法去除纺织材料表面的杂质和油脂,在机械磨皮过程中,要注意控制磨皮机的转速、压力等参数,以达到最佳的磨皮效果,在气流烘干过程中,要注意控制烘干温度和时间,以避免过度烘干或产生异味。

操作要点

(1)选择合适的清洗剂和整理剂:根据纺织材料的性质和要求选择合适的清洗剂和整理剂,不同的纺织材料需要使用不同的清洗剂和整理剂,以达到最佳的清洗和整理效果。

(2)控制工艺参数:在清洗和整理过程中,要控制温度、时间、压力等工艺参数,以达到理想的工艺效果,要注意避免过度清洗或残留物质对纺织材料造成损害。

前处理环节的注意事项与常见问题解决策略

注意事项

(1)确保前处理工艺的合规性:在进行前处理工艺时,要确保符合相关的法律法规和标准要求,要确保使用的设备和工具符合安全标准。

(2)注意环境保护:在进行前处理过程中,要尽量减少对环境的污染和对人体的危害,采用环保型的前处理工艺和方法,减少有害物质的产生和对人体的危害。

常见问题解决策略

(1)清洗不彻底:针对清洗不彻底的问题,可以采用多次清洗或加入助剂等方法进行解决,要确保清洗设备的清洁和卫生。

(2)整理效果不佳:针对整理效果不佳的问题,可以调整工艺参数或更换不同的整理剂和方法进行解决,要确保使用的设备和工具的维护和保养良好。

纺织品前处理环节是纺织生产过程中的重要环节,它涉及到对纺织材料的清洁、整理和预处理,通过本文的介绍和分析,我们可以更好地了解纺织品前处理环节的相关知识和技术细节,在实际生产中,我们需要注意合规性、环境保护等方面的问题,并采取相应的解决策略来提高纺织品的性能和质量。

Articles related to the knowledge points of this article:

The Global Fabric of Innovation

A Comprehensive Guide to Framed Textiles

The Evolution and Innovative Strategies of Guangzhou Hengye Textiles

The Art of Interior Textiles:Crafting a Masterpiece in the Canvas