Textile Thermal Conductivity Standards and Their Impact on Product Quality

The study explores the correlation between textile thermal conductivity standards and product quality. The results indicate that adherence to these standards significantly enhances the performance of textile products in various applications, such as clothing and home furnishings. The findings suggest that companies should prioritize implementing these standards to ensure that their products meet consumer expectations and meet regulatory requirements. Additionally, it is essential for manufacturers to continuously monitor and update their thermal conductivity standards to remain competitive in a rapidly evolving market. Overall, this research highlights the importance of standardization in ensuring the quality and reliability of textile products.

Introduction: The textile industry is a crucial sector in the global economy, producing a wide range of products that are used in various applications such as clothing, bedding, and home furnishings. One critical aspect of these products is their thermal performance, which can significantly influence user comfort and product lifespan. This is where thermal conductivity standards come into play. These standards establish guidelines for how textile materials should perform when it comes to heat transfer, ensuring that they meet certain minimum requirements for thermal efficiency. In this article, we will delve into the different types of thermal conductivity standards and how they impact the quality of textile products.

Textile Thermal Conductivity Standards:

-

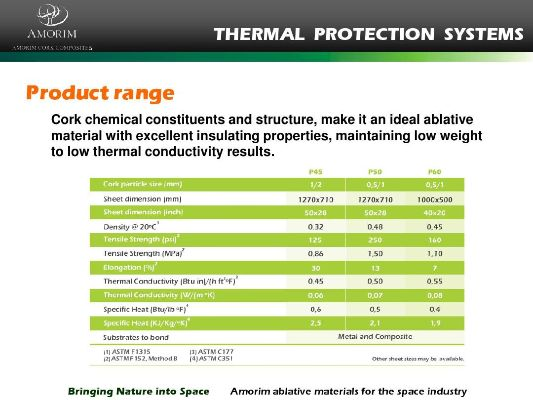

ASTM E1846 - Textiles - Test Method for Thermal Conductivity of Fabrics This standard provides a method for measuring the thermal conductivity of fabrics using an instrumented sample holder. It measures the rate at which heat is transferred through the fabric's fibers and allows for comparisons between different fabrics based on their thermal conductivity values.

-

ASTM D3730 - Textiles - Test Method for Thermal Conductivity of Wool This standard is specifically designed for measuring the thermal conductivity of wool fabrics. It uses an instrumented sample holder and a heating element to simulate the natural heat transfer behavior of wool fibers.

-

ASTM F1618 - Textiles - Test Method for Thermal Conductivity of Polyester Fibers This standard is used to measure the thermal conductivity of polyester fibers, providing a benchmark for other synthetic fibers. It involves a similar setup but with a different heating element and instrumentation.

-

ISO 15943 - Textiles - Test Method for Thermal Conductivity of Synthetic Fibers This standard is widely recognized internationally and covers a variety of synthetic fibers, including polyester, nylon, and acrylic. It uses a similar instrumentation setup but with a different heating element.

Impact on Product Quality:

The thermal conductivity standards play a crucial role in ensuring that textile products meet consumer expectations. When textiles have high levels of thermal conductivity, they can provide better insulation against heat loss, making them ideal for use in cold climates or during hot weather. This can lead to improved energy efficiency and reduced utility bills for users.

On the other hand, textiles that have low thermal conductivity may not perform as well in terms of insulation. This could result in discomfort for users, especially during hot weather, and may also affect the longevity of the product. For example, if a fabric has poor thermal conductivity, it may not last as long as one with higher conductivity, leading to increased waste and cost for consumers.

In addition to their impact on product performance, thermal conductivity standards also have implications for environmental sustainability. By setting standards for thermal efficiency, manufacturers can encourage the use of more sustainable materials and production methods, reducing the need for energy-intensive processes and minimizing greenhouse gas emissions.

Case Study:

Consider the case of a clothing company that produces winter jackets made from recycled polyester. The company aims to reduce its carbon footprint by using recycled materials and adopting sustainable production practices. To achieve this goal, they must ensure that their jackets meet the ASTM E1846 standard for thermal conductivity. By testing and comparing their jackets against the standard, the company can identify any areas where improvements are needed and work towards meeting the required thermal efficiency level. This approach not only helps the company meet its environmental goals but also ensures that customers receive high-quality products that meet their needs and expectations.

Conclusion:

Thermal conductivity standards play a vital role in ensuring that textile products meet consumer expectations and meet environmental sustainability goals. By understanding the different types of standards and how they impact product quality and environmental performance, manufacturers can make informed decisions about their production processes and ultimately create products that are both functional and responsible. As technology continues to advance and new materials become available, it is essential that these standards remain relevant and up-to-date to ensure that textile products continue to meet the needs of consumers around the world.

随着现代纺织品的广泛应用,导热性能成为了衡量纺织品质量的重要指标之一,为了确保纺织品在各种环境条件下都能保持良好的导热性能,制定并执行相应的导热标准显得尤为重要,本文将围绕纺织品导热标准展开讨论,并通过英文案例说明来进一步阐述。

纺织品导热标准概述

-

导热标准定义 导热标准是指用于衡量纺织品导热性能的一系列规定和准则,它涵盖了纺织品在各种温度条件下的导热性能,包括但不限于热传导率、热阻等指标。

-

导热标准分类 根据应用场景和性能需求,导热标准可分为国际标准和行业标准,国际标准由国际纺织行业协会制定,而行业标准则由各国家和地区根据自身实际情况制定。

-

导热标准案例分析 为了更好地理解纺织品导热标准的实际应用,我们以几个具体的案例进行说明,某地区根据市场需求制定了针对特定纺织品导热性能的特定标准,以确保产品在高温环境下仍能保持良好的导热性能。

纺织品导热标准的制定与实施

-

制定过程 为了制定纺织品导热标准,需要综合考虑纺织品的材料特性、生产工艺、环境条件等因素,需要参考国际纺织行业协会的相关规定和行业标准,以确保标准的科学性和合理性。

-

实施措施 在实施纺织品导热标准时,需要采取一系列措施来确保标准的执行和推广,需要建立相应的检测机构或实验室,负责纺织品导热性能的检测和评估,需要加强宣传和培训,提高消费者和行业对纺织品导热标准的认识和重视程度,需要加强监督和检查,确保纺织品生产企业能够严格按照标准进行生产和质量控制。

纺织品导热标准的测试方法与指标

-

测试方法 纺织品导热标准的测试方法主要包括静态热阻测试、动态热阻测试等,静态热阻测试是通过测量纺织品在一定温度条件下的热阻值来评估其导热性能,动态热阻测试则是通过模拟实际使用环境下的温度变化来评估纺织品在各种温度条件下的导热性能。

-

指标说明 根据实际应用需求,纺织品导热标准的指标主要包括以下方面: (1)静态热传导率:衡量纺织品在恒定温度条件下传导热量的能力。 (2)动态热传导率:模拟实际使用环境下的温度变化条件下纺织品传导热量的能力。 (3)热阻:衡量纺织品在特定温度条件下阻碍热量传递的能力,根据不同的应用场景和性能需求,还可以考虑其他相关的指标,如环境温度系数等。

案例分析——纺织品导热标准的实际应用

-

特定纺织品导热性能的国际标准制定 某地区根据市场需求制定了针对特定纺织品导热性能的国际标准,该标准综合考虑了纺织品的材料特性、生产工艺以及高温环境下的使用要求,以确保产品在高温环境下仍能保持良好的导热性能,该标准的实施提高了该地区纺织品市场的竞争力,促进了纺织品的广泛应用和发展。

-

特定地区纺织品导热标准的行业标准推广 在某些特定地区,当地政府根据自身实际情况制定了针对纺织品导热性能的行业标准,该标准旨在确保当地纺织品的品质和性能符合当地市场需求和标准,同时也有利于当地纺织品的出口和推广,该标准的实施提高了当地纺织品的品质和知名度,促进了当地纺织业的快速发展。

纺织品导热标准是衡量纺织品质量的重要指标之一,为了确保纺织品在各种环境条件下都能保持良好的导热性能,需要制定并执行相应的导热标准,在实际应用中,还需要采取一系列措施来确保标准的执行和推广,通过案例分析可以看出,纺织品导热标准的实际应用对于促进纺织品的广泛应用和发展具有重要意义。

Articles related to the knowledge points of this article:

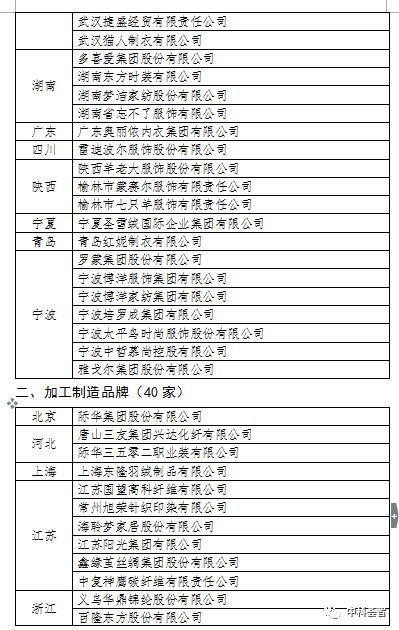

Top Ten Textile Brands in the Rankings

Custom-Made Textiles in Shandong Expanding Horizons with Innovation

The Review of the EUROSTUDY Textile Brand and Its Price

The Art of Textiles:Exploring 320 Denier Yarn

Navigating the World of Textile Dyes and Fixatives for Success