The Dynamics of Guangxis Elastic Textile Industry

In the vibrant tapestry of China's economic landscape, the Guangxi region stands out as a hub for the production of high-quality elastic textiles. This industry, known for its exceptional quality and innovative design, has not only contributed to the local economy but also played a significant role in shaping the global fashion scene. In this article, we will delve into the fascinating world of Guangxi's elastic textile industry, exploring its history, current state, and future prospects.

Historical Roots

The roots of Guangxi's elastic textile industry can be traced back to the early 20th century, when the region began to produce natural rubber from rubber trees. As demand for rubber products grew, so did the need for specialized textiles that could withstand the rigors of the rubber industry. This led to the development of advanced manufacturing techniques and the emergence of specialized factories dedicated to producing elastic textiles.

Over time, Guangxi's elastic textile industry evolved, adapting to changing market demands and technological advancements. Today, the industry is characterized by its focus on innovation, sustainability, and customer satisfaction. Many companies have invested heavily in research and development, resulting in a wide range of high-quality elastic textiles that are sought after both domestically and internationally.

Current State

Today, Guangxi's elastic textile industry is a testament to the region's commitment to excellence. According to recent data, the industry employs over 100,000 people and generates an annual revenue of over 5 billion yuan. The industry's growth has been driven by a combination of factors, including strong government support, favorable trade policies, and a growing domestic market demand.

One key aspect of Guangxi's elastic textile industry is its focus on sustainability and environmental responsibility. Many companies now use eco-friendly materials and practices, such as reducing water usage and energy consumption, to minimize their impact on the environment. Additionally, many companies are committed to promoting fair labor practices and supporting local communities.

Another important trend in the industry is the increasing focus on technology and automation. As demand for high-quality elastic textiles continues to grow, manufacturers are investing in new technologies to improve efficiency and reduce costs. This includes the use of advanced machinery, robotics, and digitalization to streamline production processes and enhance product quality.

Case Study: Xinjiang Textiles Co. Ltd.

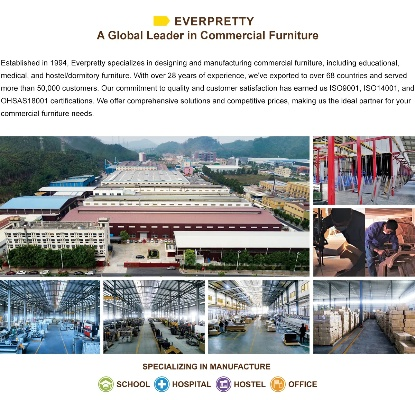

Xinjiang Textiles Co. Ltd. is a leading company in Guangxi's elastic textile industry that has made significant strides in recent years. The company was founded in 2008 and has since grown into a multi-billion-dollar enterprise that employs over 5,000 people. Xinjiang Textiles Co. Ltd.'s success can be attributed to several factors, including its commitment to innovation, sustainability, and customer satisfaction.

One key area where Xinjiang Textiles Co. Ltd. has excelled is in its use of sustainable materials and practices. The company sources its raw materials from reputable suppliers who prioritize environmental responsibility, ensuring that their products meet strict sustainability standards. Additionally, Xinjiang Textiles Co. Ltd. has implemented several measures to reduce its carbon footprint, such as using renewable energy sources and implementing waste reduction programs.

Another area where Xinjiang Textiles Co. Ltd. has excelled is in its focus on customer satisfaction. The company understands that customers expect high-quality products and excellent service, and it takes these expectations seriously. As a result, Xinjiang Textiles Co. Ltd. invests heavily in research and development to stay ahead of the competition and ensure that its products meet or exceed customer expectations.

Future Prospects

Looking ahead, the Guangxi elastic textile industry faces several opportunities and challenges. On the positive side, the industry's continued growth and expansion will continue to create job opportunities and drive economic growth in the region. Additionally, the industry's focus on sustainability and environmental responsibility will position it well for long-term success in an increasingly competitive global market.

However, the industry also faces several challenges. One major challenge is the ongoing trade tensions between China and some countries, which could affect imported materials and products. Additionally, the industry needs to continue investing in technology and automation to remain competitive in the fast-paced global market.

Despite these challenges, the Guangxi elastic textile industry remains optimistic about its future prospects. With its strong foundation in innovation, sustainability, and customer satisfaction, the industry has the potential to continue its rapid growth and become a leader in the global fashion industry.

In conclusion, the Guangxi elastic textile industry is a testament to the power of innovation, sustainability, and customer satisfaction. As the industry continues to evolve and adapt to changing market conditions, it will continue to play a vital role in shaping the global fashion scene. By embracing these values and staying true to its core principles, the Guangxi elastic textile industry can look forward to a bright future filled with endless possibilities.

广西弹性纺织厂概述

广西弹性纺织厂位于广西壮族自治区的某工业园区,是一家专注于生产高品质纺织品的现代化企业,该厂以环保、绿色、可持续为目标,致力于打造绿色制造体系,推动纺织行业的可持续发展。

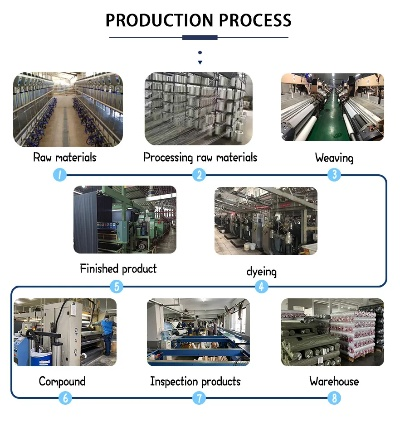

广西弹性纺织厂的生产工艺与设备

- 生产工艺:广西弹性纺织厂采用先进的纺织技术,包括纤维加工、织造、染整等环节,该厂注重产品质量和环保标准,采用环保型染料和化学剂,确保产品符合国家相关标准和环保要求。

- 设备情况:该厂拥有先进的生产设备,包括全自动织机、染整设备、检测设备等,这些设备不仅提高了生产效率,还保证了产品质量和稳定性。

广西弹性纺织厂的绿色制造实践

- 节能减排:广西弹性纺织厂注重节能减排,采用先进的节能技术和设备,减少能源消耗和污染物排放,该厂还积极推广可再生资源的使用,降低生产成本。

- 循环利用:该厂注重废旧纺织品回收和再利用,将废旧纺织品转化为其他产品,减少资源浪费和环境污染,该厂还积极推广循环经济理念,提高资源利用效率。

- 绿色供应链管理:广西弹性纺织厂注重绿色供应链管理,与供应商建立长期合作关系,确保原材料的环保和质量,该厂还积极推广绿色采购和物流管理,降低环境影响。

案例分析:广西弹性纺织厂的绿色制造实践案例

以某知名纺织企业为例,该企业在广西弹性纺织厂的绿色制造体系下取得了显著成效,该企业采用了先进的纺织技术和设备,注重环保和可持续发展,取得了良好的经济效益和环境效益。

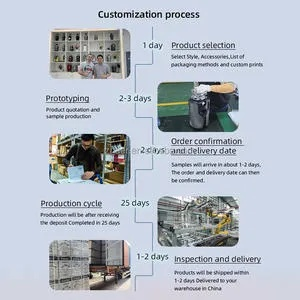

- 产品质量:该企业生产的纺织品质量稳定可靠,符合国家相关标准和环保要求,该企业还注重产品的个性化定制和品牌建设,提高了产品的市场竞争力。

- 节能减排:该企业通过采用先进的节能技术和设备,减少了能源消耗和污染物排放,该企业还积极推广可再生资源的使用,降低了生产成本,据统计,该企业在一定时间内实现了显著的节能减排效果。

- 循环利用:该企业注重废旧纺织品回收和再利用,将废旧纺织品转化为其他产品,该企业将废旧纺织品用于生产新的面料和服装,实现了资源的有效利用和循环利用,该企业还积极推广循环经济理念,提高了资源利用效率。

广西弹性纺织厂在绿色制造方面取得了显著成效,为纺织行业的可持续发展做出了积极贡献,该厂注重环保和可持续发展,采用先进的纺织技术和设备,注重废旧纺织品回收和再利用,该厂还积极推广绿色采购和物流管理,提高资源利用效率,广西弹性纺织厂将继续加强绿色制造体系建设,推动纺织行业的可持续发展。

Articles related to the knowledge points of this article:

The Story of a Textile Manufacturer:泰恒纺织厂

The Efficient Operation of Textile Factory Water Shroud Fan System

The Unexpected Turn of a Typical Workplace

A Visual Introduction to DCounty Textile Factory

The Fabric of Work:A Glimpse into the Lives of Women Textile Workers