The Impact of Cotton Finishing on the Textile Industry

Cotton finishing is a crucial step in the textile industry, as it significantly impacts the quality and performance of the final product. This process involves various steps such as dyeing, printing, and coating to enhance the appearance and durability of cotton fabrics. The choice of finishing method can greatly influence the final product's color, texture, and resistance to wear and tear. Additionally, proper finishing techniques can help to reduce environmental impact by minimizing waste and energy consumption. In conclusion, cotton finishing plays a critical role in the textile industry, and it is essential for manufacturers to invest in advanced finishing technologies to meet the demands of modern consumers.

Introduction: The textile industry is a crucial sector that generates significant economic activity worldwide. Among its many processes, cotton finishing stands out as one of the most critical stages in the production of high-quality textile products. This process involves various steps aimed at enhancing the appearance, texture, and durability of cotton fabrics. However, despite its importance, there are often concerns about the impact of cotton finishing on the environment and workers' health. In this article, we will explore the challenges and opportunities associated with cotton finishing and highlight some best practices to ensure sustainable and humane production methods.

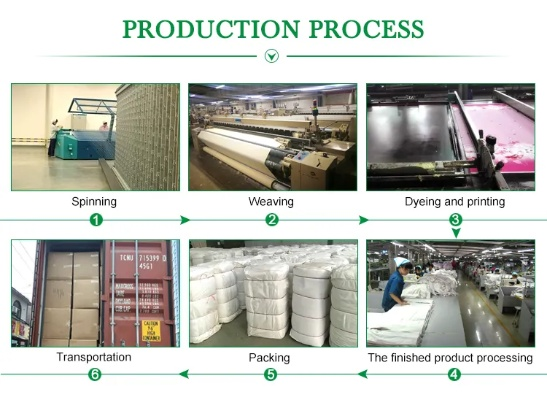

Cotton Finishing Process: Cotton finishing involves several steps to enhance the quality and performance of cotton fabrics. These steps include:

- Washing: Before finishing, cotton fabrics undergo a thorough washing process to remove dirt, oils, and other contaminants.

- Sizing: Sizing involves applying a thick layer of adhesive material to the fabric to increase its strength, elasticity, and absorbency.

- Dyeing: Dyeing is the process of applying color to the fabric using various dyes. It can be done by direct dyeing or by using a printing process.

- Treating: Treating involves applying chemicals to the fabric to improve its resistance to wear and tear, reduce shrinkage, and enhance its appearance.

- Finishing: Lastly, the fabric is given a final treatment to enhance its shine and smoothness.

Impact of Cotton Finishing on the Environment: While cotton finishing has many benefits, it also has potential negative impacts on the environment. Here are some examples of these impacts:

Waste Generation: One of the biggest environmental concerns associated with cotton finishing is the amount of waste generated. The production of cotton fabrics requires large amounts of water and energy, which contribute to pollution and climate change. Additionally, the disposal of spent dyes and chemicals can be harmful to the environment.

Water Pollution: The washing and dyeing processes used in cotton finishing can lead to water pollution. The use of toxic chemicals and excessive amounts of water can harm aquatic ecosystems and cause harm to marine life.

Energy Consumption: The energy consumption required for cotton finishing is significant, especially in countries with limited resources. The production of cotton fabrics requires large amounts of electricity and fuel, which contribute to greenhouse gas emissions and deforestation.

Worker Safety: Another concern associated with cotton finishing is worker safety. The use of toxic chemicals and hazardous machinery can pose a risk to workers' health and well-being. Moreover, the long hours and physical demands involved in the finishing process can lead to burnout and other workplace injuries.

Case Study: To address these environmental concerns, several companies have implemented sustainable practices in their cotton finishing operations. For example, Dolce & Gabbana has adopted a zero-waste policy by using recycled materials and reducing water usage during the finishing process. Additionally, the company has invested in renewable energy sources such as solar panels and wind turbines to minimize its carbon footprint.

Another example is Patagonia, a clothing brand that prioritizes ethical sourcing and sustainability in its production processes. The company ensures that its suppliers follow fair labor practices and use eco-friendly materials in their production processes. Furthermore, Patagonia invests in research and development to develop new technologies that reduce waste and minimize the environmental impact of its products.

Conclusion: In conclusion, while cotton finishing plays an essential role in the production of high-quality textile products, it also has potential negative impacts on the environment and workers' health. To address these concerns, companies must adopt sustainable practices such as zero-waste policies, renewable energy sources, and ethical sourcing. By doing so, they can not only reduce their environmental impact but also promote social responsibility and create a better future for themselves and their employees.

纺织厂棉结概述

纺织厂作为我国制造业的重要组成部分,其生产过程中的棉结问题一直是关注的焦点,棉结是指纺织过程中产生的棉籽或其他杂质在纱线中的积累,不仅影响产品质量,还可能对环境造成污染,本文将围绕纺织厂棉结现象展开讨论,并提供相关案例分析。

棉结产生原因

- 原料问题:棉花质量不佳或采摘时间不当可能导致棉结产生。

- 加工工艺:不合理的加工工艺可能导致杂质残留。

- 环境因素:不良的通风条件或湿度控制不当也可能增加棉结风险。

案例分析

以某纺织厂为例,该厂近年来面临棉结问题严重的情况,以下是该厂的详细案例分析:

原料问题

该纺织厂主要使用本地优质棉花作为原料,但由于部分棉花纤维短而粗糙,导致在加工过程中产生大量棉结,该厂在原料采购环节缺乏严格的质量控制,也增加了棉结的风险。

加工工艺

该纺织厂采用先进的加工工艺,但在某些环节仍存在操作不当的情况,在纱线梳理过程中,未能有效去除杂质,导致棉结在纱线上积累,该厂在设备维护方面也存在一定问题,影响了生产效率和质量。

棉结对生产的影响

- 影响产品质量:棉结在纱线中积累不仅影响纱线的外观和质量,还可能增加后续工序的难度和成本。

- 环境污染:棉结的积累可能对环境造成污染,包括空气污染和水质污染。

解决方案与建议

针对纺织厂棉结问题,以下是一些解决方案和建议:

- 优化原料采购:加强原料质量控制,选择优质、合适的棉花品种。

- 改进加工工艺:优化加工工艺,提高纱线梳理和杂质去除的效率和质量。

- 加强设备维护:定期对设备进行维护和保养,确保生产过程的稳定性和效率。

- 加强环保意识:加强环保宣传和教育,提高员工环保意识,减少环境污染。

- 建立质量管理体系:建立完善的质量管理体系,确保生产过程的规范性和可追溯性。

纺织厂棉结问题是一个复杂而重要的话题,它涉及到原料、加工工艺、环境等多个方面,为了解决这一问题,需要从多个方面入手,包括优化原料采购、改进加工工艺、加强设备维护、提高环保意识等,还需要建立完善的质量管理体系,确保生产过程的规范性和可追溯性,通过这些措施的实施,可以有效减少纺织厂棉结问题的发生,提高产品质量和环保水平。

Articles related to the knowledge points of this article:

The Story of Nanning Textile Factory School

The Success Story of Suining Huarun Textile Factory

The Dynamics of the Huahai Textile Factory:A Tale of Success and Innovation