The Science Behind Colorful Textiles:A Comprehensive Guide to Fabric Dyeing

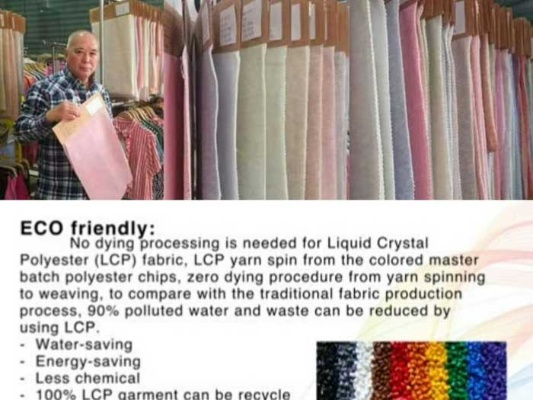

"The Science Behind Colorful Textiles: A Comprehensive Guide to Fabric Dyeing" is an in-depth guide that delves into the science behind the vibrant colors found in textiles. The book covers topics such as the chemical reactions that occur during dyeing, the types of dyes used, and the environmental impact of dyeing processes. It also provides insights into the history of fabric dyeing and the various techniques used over time.,One of the key aspects of this guide is its focus on sustainability. The authors emphasize the importance of using eco-friendly dyes and reducing waste in the dyeing process. They also discuss how to properly dispose of old dyes and other byproducts, minimizing their environmental impact.,Overall, "The Science Behind Colorful Textiles: A Comprehensive Guide to Fabric Dyeing" is a valuable resource for anyone interested in learning more about the science behind textiles and the challenges faced in achieving sustainable practices in the industry.

I. Introduction

Textile dyeing is a fascinating process that transforms fabrics into vibrant colors, adding beauty and character to clothing, home decor, and more. The ability to change the color of textiles has revolutionized the fashion industry, allowing designers to create unique looks for their collections. In this guide, we will explore the science behind coloring textiles using dyeing agents, including the various types of dyes available and their effects on the fabric. We will also discuss the factors that affect the quality and durability of dyed fabrics, as well as some practical tips for achieving successful results.

II. Types of Dyes

Acid Dyes

Acid dyes are commonly used in industrial applications and have a strong impact on fabrics. They work by breaking down the fiber structure, allowing the dye molecules to penetrate and bond with the fibers. Acid dyes are typically used for bright, bold colors and can be applied through various methods, such as pad-batch or pad-steam.

Alkaline Dyes

Alkaline dyes are gentler on fabrics and are often used for pastel or softer colors. They work by reacting with the fiber's natural amino groups, resulting in a more subtle coloration. Alkaline dyes are typically applied through dipping or spraying techniques.

Direct Dyes

Direct dyes are a type of acid dye that is specifically designed for use in textiles. They are water-soluble and can be applied directly to the fabric without the need for a backing layer. Direct dyes offer fast application times and minimal shrinkage compared to other dyeing methods.

Ester Dyes

Ester dyes are a type of alkaline dye that is commonly used for printing and screen printing applications. They are highly resistant to washing and provide a consistent color throughout the garment. Ester dyes are typically applied through screen printing or gravure printing techniques.

III. Factors Affecting Dye Quality

pH Level

pH level is a critical factor that affects the effectiveness of dyes and the final color of the fabric. An ideal pH level for most dyes is between 7 and 9, but it can vary depending on the specific dye and the fabric being treated. Higher pH levels can cause the dye to precipitate or not penetrate the fabric effectively, while lower pH levels can lead to uneven coverage or discoloration.

Temperature

Temperature plays a significant role in dyeing processes, affecting both the speed and quality of the dyeing process. High temperatures can accelerate the dyeing process and reduce the time required for color development, but they can also cause fabric shrinkage and warp during drying. Low temperatures can slow down the dyeing process and increase the time required for color development, but they can help prevent shrinkage and warp.

Chemical Composition of the Dye

The chemical composition of the dye can significantly impact its performance on the fabric. Some dyes may require special pretreatments before application to ensure optimal adhesion and coverage. Additionally, certain dyes may require additional additives, such as stabilizers or pigments, to enhance their color intensity and resistance to washing.

IV. Case Study: Successful Dyeing of a Soft T-Shirt

In this case study, we will demonstrate how to successfully dye a soft t-shirt using an alkaline dye. Here are the steps involved:

Pretreatment of the Fabric

Before applying the dye, it is important to pretreat the fabric by treating it with a mild detergent and then rinsing thoroughly. This helps remove any residual dirt or oils that could interfere with the dye's penetration and absorption.

Application of the Dye

Next, apply the alkaline dye to the fabric using a dip-dyeing machine or a spray bottle. Follow the manufacturer's instructions for the specific dye product and the recommended application rate. Ensure that the fabric is evenly coated with the dye solution.

Drying of the Fabric

After applying the dye, allow the fabric to dry naturally or use a tumble dryer at a low temperature. Avoid exposing the fabric to direct sunlight or high heat, as this can cause fading or damage to the color.

Post-Dyeing Treatment

After the fabric has dried, it is essential to treat it with a neutralizer to neutralize any remaining alkaline content and prevent future fading. Apply a neutralizing agent to the fabric and leave it to dry completely.

Final Washing

Finally, wash the fabric according to the manufacturer's instructions to ensure proper removal of any residual dye or neutralizer. Use cold water and avoid using harsh detergents, which can strip the color from the fabric.

By following these steps, you can achieve a successful dyeing process for your soft t-shirt, ensuring vibrant and long-lasting colors that look great on any outfit!

纺织品改色剂配方比例概述

在纺织品改色过程中,选择合适的配方比例是至关重要的,本篇将详细介绍纺织品改色剂的基本配方比例,并结合实际案例进行说明。

配方比例的基本要素

染料类型与颜色选择

纺织品改色剂的主要成分包括染料,根据不同的需求和目标颜色,可以选择不同的染料类型,常见的染料有活性染料、酸性染料、直接染料等,不同的染料具有不同的色泽、牢度、耐洗性等特性,应根据实际需求选择合适的染料。

配方比例的确定因素

配方比例的确定因素主要包括染料的种类、颜色深浅、织物材质、改色目的等,对于浅色织物,配方比例可以适当增加染料的浓度;对于深色织物,则需要适当降低染料的浓度,以保持颜色的鲜艳度和织物的耐久性,还应考虑织物的纤维类型、织造工艺等因素。

实际案例说明

以下是一个纺织品改色剂的实际案例,通过案例说明配方比例的重要性。

某品牌纺织品改色

该品牌需要为一款旧款纺织品改色,目标颜色为鲜艳的绿色,根据实际需求和目标颜色,选择了活性染料作为改色剂的主要成分,在配方比例方面,首先确定了染料的种类为活性染料,颜色为鲜艳的绿色,根据织物的材质和织造工艺等因素,适当调整了染料的浓度和用量,成功实现了该款旧款纺织品的改色,颜色鲜艳度得到了显著提升。

配方比例的具体示例

以下是纺织品改色剂的一些具体配方比例示例:

对于浅色织物,可以按照以下配方比例进行改色:

染料类型:活性染料(例如活性绿) 浓度:适当增加(根据织物的材质和织造工艺等因素而定) 用量:适量添加至织物中

对于深色织物,可以按照以下配方比例进行改色:

染料类型:直接染料或酸性染料(根据织物的材质和颜色深浅而定) 浓度:适当降低(确保颜色的鲜艳度和织物的耐久性) 用量:适量添加至织物中,同时考虑织物的纤维类型和工艺等因素。

总结与建议

纺织品改色剂配方比例的选择对于改色的成功与否具有至关重要的影响,在选择配方比例时,应综合考虑染料的种类、颜色深浅、织物材质、改色目的等因素,在实际操作中,还应注重工艺细节和质量控制,以确保改色的效果和质量,可以根据实际需求和目标颜色等因素,参考相关文献和案例进行配方比例的选择和调整。

Articles related to the knowledge points of this article:

Textiles Water Resistance Evaluation Checklist

Exploring the pH Profile of Macaus Textile Industry A Comprehensive Analysis