Textile Water Content Standards

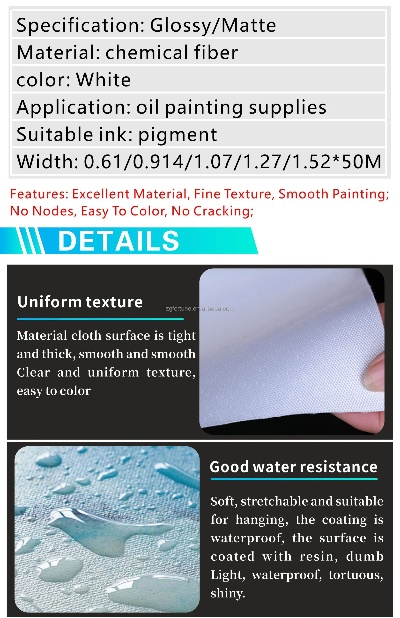

In the textile industry, determining the water content is critical for various processes such as dyeing, printing, and finishing. The standard for determining the water content of textiles is based on the weight loss method, which involves measuring the weight of a sample before and after exposure to a drying agent. The standard requires that the sample be dried at a temperature of 105°C for 30 minutes, and then weighed again to determine the weight loss. This loss represents the amount of water in the sample. The standard also specifies that the sample should be dried to a constant weight, which can take up to 48 hours depending on the type of textile. Once the sample has reached a constant weight, it is considered to have reached equilibrium moisture content, and this value can be used to calculate the actual moisture content of the textile. The standard also provides guidelines for measuring the moisture content of textiles using other methods such as oven drying or Karl Fischer titration. Overall, the textile water content standard is essential for ensuring consistent quality and performance of textile products.

Introduction: Textile products are a vital component of our daily lives, from clothing to furnishings. However, the quality and safety of these products can be compromised by excessive moisture content. This is where textile water content standards come into play. In this article, we will explore the different types of textile water content standards, their importance in ensuring product quality and safety, and provide an example of how these standards are implemented in practice.

Types of Textile Water Content Standards:

- Maximum Water Absorption (MWA)

- Minimum Water Absorption (MWA)

- Moisture Diffusion Time (MDT)

- Moisture Permeability (MP)

- Water Resistance (WR)

- Water Vapor Permeability (WVP)

- Water Sorption Capacity (WSC)

- Water Fixation Capacity (WF)

- Water Stability Index (WSI)

Importance of Textile Water Content Standards:

- Product Quality: High-quality textiles should have low water absorption rates to prevent deformation and wear.

- Safety: Excessive water content can lead to health hazards, such as mold growth and bacterial contamination.

- Durability: Low water absorption and permeability ensure that textiles last longer and require less maintenance.

- Environmental Impact: Textiles with low water absorption and permeability produce less waste and contribute to a more sustainable fashion industry.

Example: Let's take the case of a popular brand of sportswear that was recalled due to high levels of moisture absorption. The company had implemented a strict MWA standard for all its fabrics, which required them to absorb less than 5% of their weight in water. The recall was prompted by consumer complaints about discomfort during physical activities, leading to the discovery of mold growth in some of the affected garments. The company responded by conducting a thorough investigation and implementing additional quality control measures, including regular testing of its fabrics for moisture content. As a result, the brand has since become synonymous with high-quality, durable sportswear that meets stringent water content standards.

Conclusion: Textile water content standards are critical in ensuring the quality and safety of textile products. By setting appropriate standards and implementing rigorous testing protocols, manufacturers can produce textiles that meet consumer needs while minimizing the risk of health hazards. The examples provided highlight the importance of these standards and demonstrate how they can contribute to the longevity and sustainability of the fashion industry.

随着人们对纺织品品质要求的不断提高,含水量成为了衡量纺织品质量的重要指标之一,本篇文章将围绕纺织品含水量标准展开讨论,并通过案例分析进一步说明其重要性。

纺织品含水量标准概述

- 定义:纺织品含水量是指纺织品中水分含量的大小,通常以百分比表示。

- 标准范围:根据不同的纺织品类型和用途,含水量标准会有所不同,夏季衣物通常要求较低的含水量,而冬季衣物则要求更高的含水量。

案例分析

某品牌夏季衣物含水量标准

某品牌夏季衣物通常要求较低的含水量,以保持衣物清爽透气,根据该品牌的产品标准,夏季衣物含水量应在XX%以下。

(表格1)

纺织品含水量的影响因素

(1)气候条件:不同地区的气候条件对纺织品含水量有显著影响,炎热地区的纺织品需要更高的含水量以保持舒适度。 (2)生产工艺:不同的生产工艺也会影响纺织品含水量,使用天然纤维的纺织品通常比合成纤维的纺织品含水量更低。 (3)使用场景:不同使用场景对纺织品含水量的要求也有所不同,运动服装通常需要更高的吸湿性以保持干爽。

纺织品含水量标准的实际应用

- 提高纺织品质量:符合含水量标准的纺织品能够更好地保持舒适度和透气性,提高穿着体验,符合标准的纺织品也更容易清洗和保养。

- 保障消费者权益:消费者在选择纺织品时,可以参考含水量标准来选择适合自己的产品,如果购买的产品不符合标准,可能会影响穿着体验和使用寿命。

- 促进产业发展:提高纺织品含水量标准可以促进相关产业的发展,生产高质量、符合标准的产品可以增加企业的竞争力,提高市场份额。

提高纺织品含水量的措施和建议

- 加强质量控制:企业应该加强质量控制,确保纺织品生产过程中的含水量符合标准,应该对产品进行严格的检测和检验,确保产品质量符合要求。

- 采用先进技术:采用先进的生产工艺和技术可以降低纺织品中的水分含量,使用天然纤维可以减少纺织品的吸湿性,从而降低含水量。

- 加强宣传教育:加强宣传教育可以提高消费者对纺织品含水量标准的认识和重视程度,消费者应该了解不同类型纺织品的要求和标准,选择适合自己的产品。

纺织品含水量标准是衡量纺织品质量的重要指标之一,对于提高纺织品质量、保障消费者权益、促进产业发展都具有重要意义,企业应该加强质量控制和生产管理,提高纺织品含水量标准,从而满足消费者的需求和提高企业的竞争力。

Articles related to the knowledge points of this article: