Textile Functionality Finishing:Classification and Applications

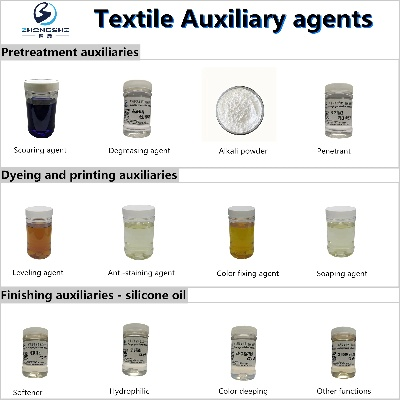

Textile Functionality Finishing: Classification and Applications,Textile functional finishing is an essential process in the textile industry, which involves applying various finishing agents to enhance the properties of textile materials. The classification of textile functional finishing can be broadly divided into three categories: adhesive finishing, coating finishing, and printing finishing. Adhesive finishing involves using adhesives to bond or attach materials together, while coating finishing involves applying a layer of material on the surface of the textile to improve its appearance or durability. Printing finishing involves creating patterns or designs on the surface of the textile using different printing techniques.,The applications of textile functional finishing are diverse and widely used in various industries. For example, adhesive finishing is commonly used in the manufacturing of garments, bags, and other textile products. Coating finishing is used in the production of carpets, upholstery, and other textiles to improve their appearance and durability. Printing finishing is used in the production of promotional materials, such as T-shirts, hats, and other apparel items. In addition, functional finishing can also be applied to protect textiles from wear and tear, such as by adding antibacterial agents or flame retardants.

Introduction

Textile functionality finishing is a crucial process in the textile industry that aims to enhance the performance, durability, and aesthetic appeal of fabrics. It involves applying chemicals or treatments to fabrics to improve their specific properties, such as anti-bacterial properties, flame resistance, moisture management, and colorfastness. In this article, we will discuss the classification of textile functionality finishing and its various applications.

Classification of Textile Functionality Finishing

Anti-Bacterial Treatments

Anti-bacterial finishing is a type of functionality finishing that kills or inhibits the growth of bacteria on fabrics. This treatment helps prevent the spread of infections caused by bacteria, such as those found on hospital gowns, surgical scrubs, and other healthcare products. The most common anti-bacterial finishing agents are quaternary ammonium compounds, which are effective against both Gram-positive and Gram-negative bacteria.

Flame Retardant Treatments

Flame retardant finishing is used to make fabrics less likely to catch fire. This treatment can be applied to cotton, polyester, and other synthetic fibers to reduce the risk of fire outbreaks. Flame retardants include phosphorus compounds, halogenated compounds, and silicone additives.

Moisture Management Treatments

Moisture management finishing is designed to control the amount of water absorbed by fabrics. This treatment helps prevent mold growth and maintain the quality of fabrics, especially in outdoor applications like tents, raincoats, and beach towels. Moisture management treatments can be achieved through chemical treatments or physical methods, such as coating fabrics with a hydrophobic finish.

Colorfastness Treatments

Colorfastness finishing is used to ensure that fabrics retain their colors over time. This treatment can be applied to cotton, linen, and other natural fibers to improve their resistance to fading and creasing. Colorfastness treatments typically involve the use of dyes and pigments that have been treated with special chemicals to enhance their stability.

Applications of Textile Functionality Finishing

Medical Equipment

Medical equipment manufacturers use anti-bacterial finishing to ensure that their products are safe for patients. For example, hospitals require gowns and scrubs to be free from harmful bacteria, and medical devices must be resistant to bacterial contamination.

Outdoor Products

Outdoor products companies use flame retardant finishing to create fabrics that are less likely to catch fire. This is particularly important for clothing, tents, and other outdoor gear that may come into contact with open flames.

Sportswear

Sportswear companies use moisture management finishing to create fabrics that are more breathable and comfortable. This is especially important for sports apparel that may get wet during exercise.

Home Decor

Home decor companies use colorfastness finishing to ensure that their fabrics remain vibrant and attractive over time. This is particularly important for upholstery, curtains, and other items that may be exposed to sunlight and other environmental factors.

Case Study: Anti-Bacterial Treatments in Hospital Gowns

In recent years, there has been an increasing demand for hospital gowns that are not only comfortable but also safe for patients. To meet this demand, many hospitals have started using anti-bacterial finishing to create gowns that are resistant to bacterial contamination. For example, one hospital in California began using a quaternary ammonium compound to treat their hospital gowns. After two years of use, the hospital found that the gowns were significantly less likely to harbor bacteria than before. This led to a significant reduction in the number of infections caused by bacteria on the hospital's patient care units.

Conclusion

Textile functionality finishing plays an essential role in enhancing the performance and safety of fabrics. By classifying and understanding different types of functionality finishing, we can better understand how they can be applied to specific industries and products. As technology continues to advance, it is likely that we will see even more innovative and effective functional finishing treatments in the future.

在纺织品的生产和销售过程中,纺织品的功能整理是一个重要的环节,为了更好地理解和掌握纺织品功能整理的分类,本文将通过表格和案例说明的方式,详细介绍纺织品功能整理的分类及其应用。

纺织品功能整理的分类

按整理目的分类

(1)舒适整理:通过改变纤维的物理性质,提高穿着舒适度,柔软整理、抗皱整理等。

(2)美观整理:通过改变纤维的颜色、图案等,提高纺织品的美观度,印花整理、提花整理等。

(3)功能性整理:根据特定需求进行整理,如防污、防紫外线、吸湿排汗等。

按整理工艺分类

(1)机械整理:通过机械力改变纤维的结构和性能,如织造过程中的牵伸、定形等。

(2)化学整理:使用化学试剂或添加剂对纤维进行整理,如染色整理、防污整理等。

(3)生物整理:利用生物技术对纤维进行整理,如生物降解整理、抗菌整理等。

按应用领域分类

(1)服装面料整理:包括针织面料、梭织面料等各类服装面料的整理。

(2)家居纺织品整理:如地毯、窗帘、床单等家居用品的整理。

(3)工业纺织品整理:用于各种工业用途的纺织品,如过滤材料、防护服等。

案例说明

以服装面料为例,展示纺织品功能整理的具体应用和分类。

服装面料的功能整理主要包括舒适整理、美观整理和功能性整理,舒适整理可以通过柔软剂、抗皱剂等化学试剂或添加剂来实现;美观整理可以通过印花工艺、提花工艺等工艺手段来实现;功能性整理则可以根据服装的需求,选择相应的防污、防紫外线、吸湿排汗等功能性面料。

在具体案例中,我们可以看到不同的纺织品功能整理的应用场景和效果,某品牌的高档西装面料采用了生物降解整理技术,不仅提高了面料的环保性能,还提高了面料的吸湿排汗性能,使得穿着更加舒适,某品牌的地毯面料采用了化学染色整理技术,提高了地毯的色彩鲜艳度和耐洗性,这些案例充分展示了纺织品功能整理的多样性和实用性。

纺织品功能整理的分类多种多样,可以根据不同的目的和领域进行分类,在实际应用中,我们可以根据具体的需求和场景选择合适的纺织品功能整理方法和技术,随着科技的不断发展和创新,纺织品功能整理的技术和工艺也在不断进步和完善,为纺织品的生产和销售提供了更多的选择和可能性。

Articles related to the knowledge points of this article:

Exploring the World of Textiles:A Glossary of Different Fabric Materials

The Journey of Exquisite Durable Textiles an Insight into 秀力达纺织品

Stitching Up Fashion:Crafting the Look with Textile Materials