The Fabric of Innovation:Unraveling the World of Non-Woven Fabrics

"The Fabric of Innovation: Unraveling the World of Non-Woven Fabrics",This article explores the intricate fabric of innovation in non-woven fabrics, a category of materials that has revolutionized the world of textiles. By delving into the history and development of non-woven fabrics, we uncover the underlying principles that have made them so effective and versatile.,Non-woven fabrics are characterized by their unique structure, which consists of multiple layers of fibers that are randomly arranged to create a three-dimensional network. This structure provides excellent strength, durability, and breathability, making it ideal for applications such as protective clothing, sportswear, and automotive parts.,The fabric of innovation in non-woven fabrics is rooted in the continuous advancements in technology and research. From the introduction of new fibers and polymers to the development of advanced manufacturing processes, there has been a constant drive towards creating more sustainable and efficient materials.,In conclusion, the fabric of innovation in non-woven fabrics is a testament to the creativity and ingenuity of human beings. As we continue to push the boundaries of what is possible, we can expect to see even greater breakthroughs in this field, leading to even more innovative and impactful applications in our daily lives.

In the realm of textiles, the unwoven fabric is a cornerstone that underpins our everyday lives. It's not just about the aesthetic appeal or practicality; it's about the science behind creating a seamless and durable surface that can withstand the test of time. In this conversation, we will delve into the world of non-woven fabrics, exploring their myriad uses, the techniques that drive their production, and the impact they have on the global textile industry. Let's start by breaking down the basics.

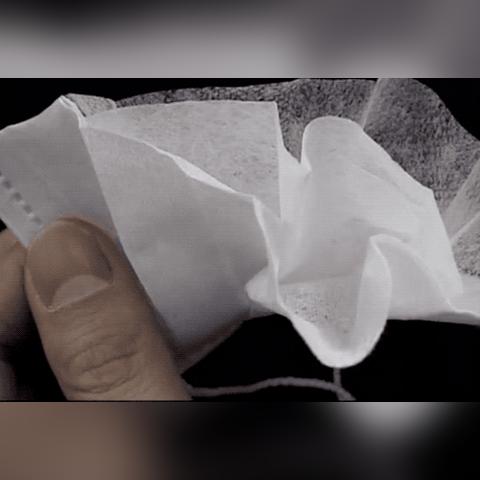

Unwoven fabrics are characterized by their lack of interlacing or stitching, allowing them to be formed from continuous filaments. This characteristic gives them a unique strength and resilience that sets them apart from traditional woven fabrics. They are often referred to as "non-woven" because they don't follow the traditional pattern of threads crossing each other in a grid-like structure. Instead, they are composed of individual fibers that are randomly arranged in a three-dimensional structure. This structure provides them with a high level of flexibility, breathability, and durability, making them ideal for a variety of applications.

The production process involves several stages, starting with the selection of raw materials such as polyester, cotton, or even recycled materials. These raw materials undergo various processes to transform them into usable fibers. For instance, polyester is melted and extruded through a spinneret to form long filaments. Then, these filaments are directed towards a die where they are further processed into the desired shape. The final step involves the formation of the non-woven fabric by passing the filaments through a machine that forms a web. The process is repeated multiple times to create a continuous layer of fibers.

Non-woven fabrics come in a wide range of applications, from everyday items like clothing and household goods to more specialized ones like medical equipment, automotive parts, and sportswear. One of the most prominent examples is the use of non-woven fabrics in the production of medical masks. These masks are made from layers of non-woven fabric that trap airborne particles, providing an effective barrier against respiratory infections. Another area where non-woven fabrics shine is in the automotive industry. They are used in the construction of protective gear for drivers and passengers, as well as in the manufacturing of car interiors.

To understand the impact of non-woven fabrics on the global textile industry, it's essential to look at some key statistics. According to a report by Textile Exchange, the global non-woven market size was valued at $18 billion in 2020, with a compound annual growth rate (CAGR) of 4.3% over the forecast period of 2020 to 2027. This growth is attributed to the increasing demand for sustainable and eco-friendly materials in various sectors, including healthcare, sportswear, and home furnishings.

One example of how non-woven fabrics are revolutionizing the fashion industry is seen in the development of eco-friendly denim. Brands like Patagonia are using non-woven fabrics made from recycled materials to produce their denim products, which not only reduce their carbon footprint but also provide consumers with a sustainable option. Similarly, the growing popularity of outdoor activities has led to an increase in demand for high-quality, breathable, and weatherproof outerwear made from non-woven fabrics.

In conclusion, the world of non-woven fabrics is a vast and dynamic one, with endless possibilities for innovation and application. From everyday items to specialized industries, non-woven fabrics are transforming the way we live and interact with the world around us. As technology continues to advance and new materials are discovered, we can expect to see even more exciting developments in the future. So grab your pen and notebook, because this is an exciting journey into the world of non-woven fabrics!

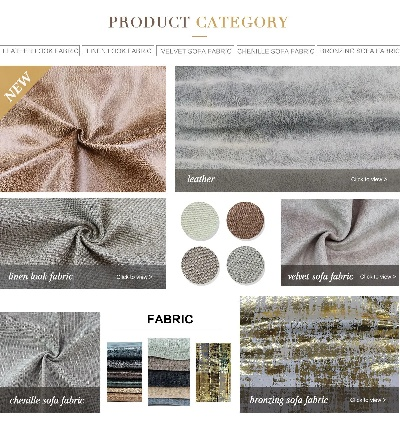

纺织品无纺布简介

纺织品无纺布是一种新型的环保材料,具有轻便、耐用、易加工等优点,它是由纤维材料经过特殊处理,形成一种无织造结构的薄膜或片状材料,无纺布的应用范围广泛,包括但不限于服装、家居装饰、包装材料等。

无纺布的种类与特点

- 聚酯纤维无纺布:这是一种常见的无纺布材料,具有高强度、耐磨、抗皱等特性,它适用于制作各种户外用品、运动装备等。

- 纯棉无纺布:纯棉无纺布是一种天然纤维材料,具有柔软、透气、吸湿性好等特点,适合制作各种内衣、家居用品等。

- 纳米纤维无纺布:纳米纤维无纺布具有超强的抗拉强度和耐磨性,同时具有很好的透气性和吸湿性,适用于制作高科技产品包装。

无纺布的应用案例

服装行业案例

在服装行业中,无纺布因其轻便、耐用、易加工等特点,被广泛应用于制作各种时尚服装,某品牌的高端运动服采用聚酯纤维无纺布制作,不仅保证了服装的舒适度和耐用性,还提升了整体的时尚感。

家居装饰行业案例

在家居装饰行业中,无纺布因其环保、美观等特点,被广泛应用于制作各种家居用品,某品牌的家居装饰品采用纯棉无纺布制作,不仅具有良好的透气性和吸湿性,还体现了环保理念。

无纺布的生产工艺与流程

- 生产工艺:无纺布的生产工艺主要包括纤维原料的选择与处理、薄膜的制备与成型、后处理等步骤,纤维原料的选择与处理是关键环节,需要严格控制纤维的质量和纯度。

- 流程:选择合适的纤维原料进行加工;经过预处理、熔融、挤出等工序,形成薄膜或片状材料;然后进行后处理,如切割、裁剪等工序,得到最终的无纺布产品。

无纺布的市场前景与趋势

- 市场前景:随着人们对环保、可持续性生活方式的追求,无纺布作为一种新型环保材料,具有广阔的市场前景,随着技术的不断进步和产品创新,无纺布的应用领域还将不断扩大。

- 趋势:随着科技的不断进步和消费者需求的不断变化,无纺布的生产工艺和产品形态也在不断发展和创新,无纺布将更加注重环保、美观、耐用等方面的发展。

纺织品无纺布作为一种新型环保材料,具有广泛的应用前景和市场需求,随着技术的不断进步和产品创新,无纺布的应用领域还将不断扩大,无纺布的生产工艺和产品形态也在不断发展和创新,为人们的生活带来了更多的便利和舒适。

Articles related to the knowledge points of this article:

The Journey of Golden Beads:The Story of 金豆豆纺织品