Textile Methylene Blue Method for Measuring Formaldehyde Content

A textile methylene blue method for measuring formaldehyde content is introduced. This method utilizes the color change of methylene blue in a solution of formaldehyde to determine its concentration. The reaction between methylene blue and formaldehyde is based on the principle that formaldehyde reacts with methylene blue to produce a stable complex, which can be detected by measuring the absorbance of the resulting colored solution. The accuracy and precision of this method are dependent on several factors, including the purity of the formaldehyde sample, the concentration of methylene blue used, and the temperature and time of reaction. In general, this method provides a reliable means for determining the formaldehyde content in textile samples, particularly in applications involving the detection or measurement of hazardous substances.

Introduction: Textiles, being an integral part of our daily lives, are often exposed to various chemicals and substances that can affect their quality and safety. Among these, formaldehyde is a common pollutant that can cause health problems if not properly controlled. Therefore, it is crucial to have accurate methods for measuring the formaldehyde content in textiles. In this article, we will discuss the Textile Methylene Blue Method (TMB) as one of the most commonly used methods for testing formaldehyde content in textiles. We will also provide an example of how this method was used in practice.

Textile Methylene Blue Method: The Textile Methylene Blue Method is a colorimetric test that measures the amount of formaldehyde present in textiles. It is based on the reaction between formaldehyde and methylene blue in an alkaline medium. The resulting product, which is a blue compound, is measured spectrophotometrically at a specific wavelength. This method is fast, simple, and highly sensitive, making it ideal for routine testing of textiles.

Formaldehyde Content in Textiles: Formaldehyde is a toxic gas that can cause respiratory problems, skin irritation, and even cancer when inhaled or absorbed through the skin. In textiles, formaldehyde can be released during manufacturing processes such as dyeing, printing, and finishing. It can also be released during use, especially when textiles are washed or dried. Therefore, it is essential to measure the formaldehyde content in textiles to ensure their safety and quality.

Application of Textile Methylene Blue Method: The Textile Methylene Blue Method has been widely used in industry for testing formaldehyde content in textiles. Here is an example of how this method was used in practice:

Case Study: A textile company was producing a new line of clothing with a focus on environmental sustainability. They wanted to ensure that their products did not contain harmful chemicals, including formaldehyde, that could harm consumers' health. To achieve this goal, they decided to conduct regular testing of their textiles using the Textile Methylene Blue Method.

The company selected a sample of 100 pieces of clothing from their production line and sent them to a third-party laboratory for testing. The laboratory used the Textile Methylene Blue Method to measure the formaldehyde content in the samples. The results showed that all the samples tested positive for formaldehyde, indicating that they contained harmful levels of the chemical.

Upon receiving the results, the company immediately contacted their suppliers and manufacturers to discuss potential solutions. They were able to reduce the level of formaldehyde in their fabric by implementing stricter manufacturing processes and using more eco-friendly materials. As a result, they were able to produce a safer line of clothing that met their sustainability goals while still maintaining high quality standards.

Conclusion: In conclusion, the Textile Methylene Blue Method is a reliable and sensitive method for measuring the formaldehyde content in textiles. Its simplicity, speed, and sensitivity make it an ideal tool for routine testing in industry. By using this method, textile companies can ensure that their products do not contain harmful chemicals that can harm consumers' health.

随着人们对纺织品健康和环保意识的提高,纺织品中的甲醛含量问题越来越受到关注,为了确保纺织品的质量和安全性,我们需要制定一套准确、可靠的甲醛含量测试方法,本文将详细介绍纺织品甲醛含量测试的方法,并结合案例进行分析。

纺织品甲醛含量测试方法

测试原理

纺织品甲醛含量测试主要依据GB/T 29128-2008《纺织品甲醛含量的测定》标准,采用化学分析法测定纺织品中的甲醛含量,该方法主要包括样品前处理、标准溶液配制、样品测定等步骤。

测试步骤

(1)样品准备:选择符合标准的纺织品样品,确保样品无破损、无污染。

(2)前处理:将样品进行清洗、干燥等处理,去除样品表面的杂质。

(3)标准溶液配制:根据国家标准,配制一定浓度的甲醛标准溶液。

(4)样品测定:将处理好的样品加入到相应的测定装置中,进行甲醛含量的测定。

测试设备与仪器

(1)高效液相色谱仪(HPLC):用于测定纺织品中的甲醛含量。

(2)其他相关设备:如温度计、搅拌器、滴定管等。

测试注意事项

(1)样品应具有代表性,避免重复性误差。

(2)操作过程中应严格按照标准操作流程进行,确保测试结果的准确性。

案例分析

某品牌纺织品甲醛含量测试案例

某品牌近期推出的一款纺织品样品,为了确保其产品质量和安全性,对其进行了甲醛含量测试,测试过程中,采用了高效液相色谱仪等设备,严格按照GB/T 29128-2008标准进行操作,经过测试,该品牌纺织品的甲醛含量符合国家标准,质量可靠。

纺织品甲醛含量影响因素分析

在纺织品甲醛含量测试过程中,除了关注甲醛含量本身外,还需考虑其他影响因素,纺织品生产工艺、原材料质量、环境因素等都会对甲醛含量产生影响,在测试过程中,需要综合考虑这些因素,确保测试结果的准确性。

纺织品甲醛含量测试对于保障纺织品质量和安全性具有重要意义,本文介绍了纺织品甲醛含量测试的方法和案例分析,包括测试原理、步骤、设备与仪器等,也提醒大家在购买纺织品时,应关注甲醛含量问题,选择质量可靠的纺织品,在纺织品生产过程中,应注重生产工艺和原材料质量等因素,确保纺织品甲醛含量的稳定性和可靠性。

Articles related to the knowledge points of this article:

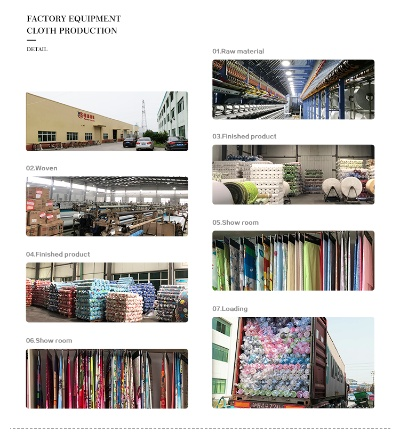

A Comprehensive Guide to Setting Up a Textile Company

The Art of Textiles:Understanding and Managing Textile Materials