纺织品采样规范

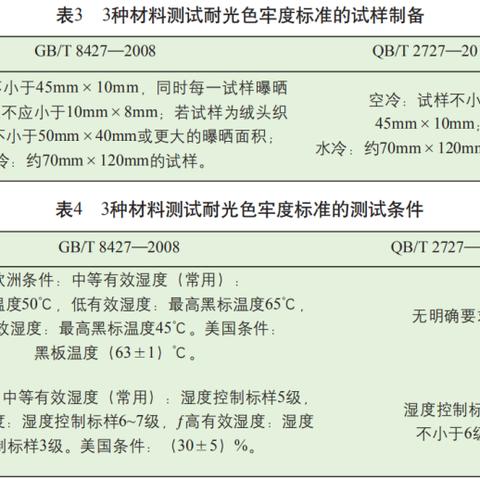

: Standards for Fabric Sampling,In the textile industry, accurate and reliable sampling is crucial for ensuring consistent quality control measures. The following are the general standards for fabric sampling:,1. **Sampling Area**: The sample should be representative of the entire piece of fabric. It is recommended to collect samples from different areas of the fabric to ensure that the overall quality is consistent.,2. **Sampling Technique**: Use a sterile technique to avoid contamination during sampling. A sterile scalpel or tweezers should be used to remove small pieces of fabric for analysis.,3. **Sample Preparation**: Before analysis, the sample should be properly preserved in a sealed container. This helps to prevent degradation of the sample and ensures its integrity for further testing.,4. **Quality Control**: Regularly check the quality of the samples to ensure consistency in the results. If any issues arise, resample the area until satisfactory results are obtained.,5. **Documentation**: Keep detailed records of the sampling process, including the location, size, and type of fabric sampled. This information can be useful for future reference and quality assurance.,By adhering to these standards, textile companies can ensure that their products meet the highest quality requirements and provide customers with confidence in their products' quality.

Introduction: In the world of textiles, quality control is paramount. One critical aspect of ensuring product quality is proper sampling techniques. This guide aims to provide a comprehensive overview of how to conduct effective textile sampling, including the importance of sampling protocols and the various tools and techniques that can be used in the process. By following these guidelines, businesses can ensure they are collecting accurate and representative samples for quality testing and analysis.

Sampling Procedures: The first step in any sampling procedure is to define the purpose of the sample. This will determine the type of sample required, such as bulk, cut, or spot samples. Once this has been established, it's important to select a sampling method that best suits the specific requirements of the project. Common methods include random sampling, systematic sampling, and judgment sampling.

Random Sampling: Random sampling involves selecting a random number of samples from the entire population. This method is useful when the population is large and homogeneous, but it may not be representative of the entire population if there are significant differences in size or composition.

Systematic Sampling: Systematic sampling involves selecting consecutive numbers of samples from the entire population. This method is useful when the population is large and non-homogeneous, as it ensures that all parts of the population are represented. However, it may result in fewer samples being collected than necessary if the population is very large.

Judgment Sampling: Judgment sampling involves selecting samples based on judgment rather than a set formula. This method is often used when there is a limited amount of time or resources available and the objective is to obtain a representative sample quickly. However, it is essential to ensure that the selected samples are truly representative of the entire population.

Tools and Techniques: Once the sampling method has been chosen, it's important to have the right tools and techniques at hand. Some common tools include a sampling frame, a sampler, and a data collection form. The sampling frame is a reference point used to identify each individual sample. The sampler is a tool used to collect samples from the population, while the data collection form is used to record information about each sample.

Sampling Errors: It's important to understand the potential errors associated with sampling. These errors can occur due to factors such as bias, non-response, and contamination. To minimize these errors, it's essential to follow strict sampling procedures, use appropriate tools and techniques, and ensure that the sampling frame is accurate.

Case Study: Let's take a look at an example of how sampling works in practice. Suppose a textile company is developing a new fabric blend and needs to test its performance under different conditions. To do this, they decide to conduct a random sampling experiment. They select a population of 1000 samples from their production line and randomly assign them to one of three treatment groups. Each group represents a different condition, such as hot water washing, dry cleaning, and normal wear and tear. After the experiment is complete, they analyze the data and compare the results to determine which treatment group performs best.

Conclusion: In conclusion, proper sampling techniques are essential for ensuring accurate and reliable results in textile quality control. By following the guidelines outlined in this guide, businesses can develop effective sampling procedures that help them achieve their goals. Remember, sampling is just one part of the overall quality control process, so it's important to work closely with other quality control measures to ensure consistent results.

Articles related to the knowledge points of this article:

The Dynamics of Nan Yixin Textile Industry:A Comprehensive Analysis

Top Ten Textile Brands in the Rankings:High-Resolution Images and Case Studies