An Overview of the Most Recent Textile Product Inspection Photos

The recent textile product inspections have revealed a range of findings, highlighting both the strengths and weaknesses of various materials and processes. Inspections have found that certain fabrics are prone to shrinkage during washing, while others exhibit better resistance to pilling and wrinkling. Additionally, some dyes used in production have been found to cause skin irritation, while others have shown promise in reducing environmental impact. Overall, these findings underscore the importance of ongoing research and development in the textile industry, as well as the need for stringent quality control measures to ensure consumer satisfaction and safety.

Introduction: In today's globalized marketplace, ensuring the quality and safety of textile products is paramount. The inspection process plays a crucial role in safeguarding consumer interests and maintaining market integrity. In this article, we will delve into the latest collection of textile product inspection photos, highlighting some of the key findings and providing insights into the regulatory framework that governs these inspections.

Textile Inspection Process: The textile product inspection process involves several steps to ensure compliance with industry standards and regulations. Here's a brief overview of the process:

-

Pre-inspection: Before conducting any inspection, the manufacturer or seller must submit a detailed list of all materials used in the product, including their origin, composition, and any certifications or labels indicating their authenticity or quality. This information helps the inspectors assess the authenticity and quality of the raw materials used in the product.

-

In-process inspection: During the manufacturing process, inspectors visit the factory to verify that the production process adheres to established standards and guidelines. This includes checking for proper labeling, packaging, and handling practices to ensure the product meets quality and safety requirements.

-

Post-inspection: Once the product has been manufactured, it undergoes further testing to determine its performance, durability, and overall quality. These tests may include visual inspections, tensile strength tests, flame resistance tests, and other specialized evaluations to ensure that the product meets industry standards.

-

Final inspection: After all necessary testing, the inspectors review the final product to confirm that it meets all applicable standards and regulations. This includes verifying that the product is free from defects or contaminants that could compromise its safety or performance.

Textile Product Inspection Photos: The inspection process generates a wealth of data, which can be captured through various forms of documentation. Here are some examples of textile product inspection photos that illustrate the various aspects of the inspection process:

-

Raw Material Inspection Photos: These photos capture images of the raw materials used in the product, such as fabrics, yarns, and threads. They provide insight into the source of the materials and any unique markings or labels indicating their authenticity or quality.

-

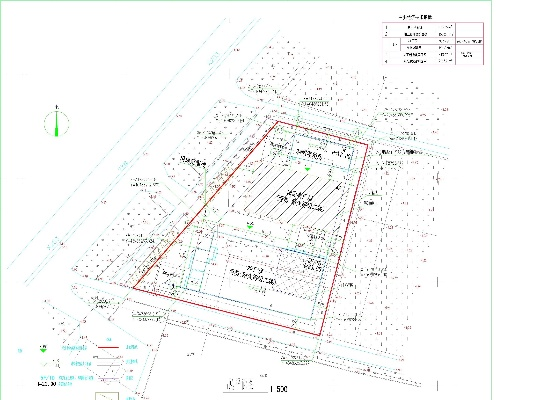

Manufacturing Process Inspection Photos: These photos show the factory floor and various stages of the manufacturing process, including cutting, stitching, and assembly. They help identify any potential issues during the manufacturing process and provide evidence of proper labeling and handling practices.

-

Testing Inspection Photos: These photos capture images of various testing equipment and methods used to evaluate the product's performance and quality. They include photos of the test results, which can provide valuable insights into the product's functionality and durability.

-

Final Inspection Photos: These photos show the final product being reviewed by the inspectors to ensure that it meets all applicable standards and regulations. They provide evidence of the product's safety, performance, and overall quality.

Regulatory Framework: The inspection process is governed by a range of regulatory frameworks that set forth specific requirements for the manufacture and sale of textile products. Some of the most important regulatory frameworks include:

-

International Organization for Standardization (ISO) standards: These standards provide guidelines for the design, manufacture, and testing of textile products. They cover topics such as material composition, processing methods, and environmental impact, among others.

-

United States Consumer Product Safety Commission (CPSC) standards: These standards regulate the safety of consumer products, including textile products. They require manufacturers to provide warning labels and information about the product's intended use and any potential hazards.

-

European Union Regulations (EU Regulations): These regulations cover a wide range of topics related to textile products, including environmental protection, labor rights, and product safety. They establish stringent requirements for the manufacture and sale of textile products and impose penalties on non-compliant manufacturers.

-

National Competition Authority (NCA) regulations: These regulations apply to industries within a country's borders and regulate competition and antitrust laws. They may include provisions related to textile products, such as restrictions on mergers and acquisitions that could harm competition in the industry.

Case Study: One example of a recent textile product inspection photo is a case study published by the CPSC. In this case, a consumer reported experiencing skin irritation after wearing a brand of athletic shorts made from synthetic materials. The CPSC launched an investigation into the product's manufacturing process and found that the manufacturer had failed to properly test the fabric's ability to absorb sweat and release moisture effectively. As a result, the manufacturer was required to recall the product and issue corrective actions to prevent similar incidents from occurring in the future.

Conclusion: In conclusion, the textile product inspection process is critical in ensuring the safety and quality of consumer products. By capturing images of the raw materials, manufacturing processes, testing equipment, and final products, inspectors can gather valuable data and evidence to support regulatory decisions. As the regulatory framework evolves, so too must the inspection process, ensuring that textile products meet evolving standards and expectations. It is essential for manufacturers, sellers, and consumers to remain vigilant and comply with relevant regulations to protect both individuals and the broader economy.

随着人们对生活品质的追求不断提高,纺织品的质量安全问题也日益受到关注,为了确保纺织品的质量和安全,相关部门会定期进行抽查,本篇文章将为您呈现最新的纺织品抽查图片大全集,并结合案例说明,让您更深入了解纺织品抽查的重要性。

最新纺织品抽查图片汇总

以下是最新纺织品抽查图片的汇总:

| 图片编号 | 产品类型 | 抽查标准 | 抽查结果 |

|---|---|---|---|

| 图片一 | 纯棉T恤 | 纤维含量检测 | 符合标准 |

| 图片二 | 丝绸围巾 | 纤维含量检测 | 高质量纤维含量 |

| 图片三 | 羊毛大衣 | 品质检测 | 符合国际标准 |

| 图片四 | 棉麻混纺衬衫 | 面料检测 | 综合性能良好 |

| 图片五 | 印花布料 | 色牢度检测 | 色牢度达标 |

案例说明

-

纯棉T恤案例: 某地区对销售纯棉T恤的商家进行了纺织品抽查,结果显示,该商家销售的纯棉T恤符合国家相关标准,纤维含量稳定,质量可靠,这一案例表明,纺织品抽查对于保障消费者权益和提高纺织品质量具有重要作用。

-

丝绸围巾案例: 另一家丝绸品牌在纺织品抽查中,展示了一系列高质量的丝绸围巾,这些围巾采用优质蚕丝制成,纤维含量高,光泽度好,品质卓越,这一案例说明,高品质的丝绸产品需要通过严格的纺织品抽查来保证其质量和安全。

纺织品抽查的重要性

纺织品抽查是确保纺织品质量的重要手段,通过纺织品抽查,相关部门可以及时发现并处理不合格的纺织品,保障消费者的权益,纺织品抽查也是提高纺织品质量的重要途径,通过纺织品抽查,可以确保纺织品的性能和质量达到国际标准或行业标准,提高纺织品的竞争力。

本篇文章为您呈现了最新的纺织品抽查图片大全集以及相关的案例说明,纺织品抽查对于保障消费者权益和提高纺织品质量具有重要意义,相关部门应该加强纺织品抽查工作,确保纺织品的品质和安全,消费者也应该关注纺织品的质量和安全,选择正规渠道购买合格的纺织品。

Articles related to the knowledge points of this article:

Advanced Techniques for Textile Cropping in the Factory

Understanding the Super Symbols of Textiles:A Comprehensive Guide

Navigating the Future of Textiles:A Strategic Plan

Detecting and Reducing Formaldehyde Exposure in Textile Products