The Fabric of Innovation:An Insight into the Chateng Textile Factory Workshop

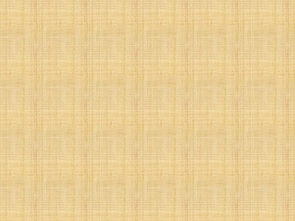

: The Fabric of Innovation: An Insight into the Chateng Textile Factory Workshop,The Chateng Textile Factory, a renowned producer of high-quality textiles in China, has long been recognized for its innovative approach to manufacturing. This factory's workshop is a testament to the company's commitment to fostering creativity and technological advancement within its workforce.,Through meticulous design and execution, the workshop is equipped with state-of-the-art machinery that ensures consistent quality and efficiency in the production process. The use of advanced technology not only enhances the product's aesthetic appeal but also reduces waste and improves productivity.,Furthermore, the Chateng Textile Factory's workshop emphasizes the importance of teamwork and collaboration among employees. The factory encourages cross-functional teams to brainstorm ideas and come up with innovative solutions to problems encountered during production. This collaborative approach has led to numerous successful projects and products that are both functional and visually appealing.,In conclusion, the Chateng Textile Factory's workshop embodies the essence of innovation and creativity. Its commitment to excellence, combined with the dedication of its staff, has resulted in a factory that stands out as a leader in the industry.

Introduction: In the tapestry of China's industrial landscape, the textile industry stands out as a beacon of progress and innovation. Among the many factories that contribute to this sector, the Chateng Textile Factory has emerged as a model of excellence, showcasing how traditional craftsmanship meets cutting-edge technology to produce high-quality textiles. Today, we delve into the world of the Chateng Textile Factory workshop, exploring its unique processes, innovative techniques, and the remarkable impact it has had on the local economy and the global market.

The Workshop: A Workplace of Craftsmanship

At the heart of the Chateng Textile Factory lies a workshop that embodies the essence of craftsmanship. Here, skilled artisans work tirelessly to transform raw materials into high-end textiles. The process starts with selecting the finest yarns, which are then spun into thread by experienced spinners. This is followed by knitting, weaving, and finishing stages, each one meticulously executed to ensure the final product meets stringent quality standards.

One such example is the use of eco-friendly dyes in the production of sustainable textiles. Innovative dyeing techniques have been developed to minimize environmental impact while maintaining vibrant colors. These techniques not only reduce waste but also enhance the longevity of the fabric, making it more durable and resistant to wear and tear.

Another highlight is the use of advanced computerized machines that automate the knitting and weaving processes. These machines not only speed up the production cycle but also allow for precise control over the thickness and texture of the fabric, resulting in exceptional quality.

Technological Advancements: The Future of Textile Production

As the Chateng Textile Factory continues to evolve, it is embracing technological advancements to stay ahead of the curve. For instance, the factory has invested in state-of-the-art robotic weaving machines that can handle large volumes of fabric with precision and efficiency. These machines are designed to work around the clock without fatigue, ensuring consistent quality output.

Furthermore, the factory has adopted smart manufacturing systems that integrate data analytics to optimize production processes. By analyzing production data, managers can make informed decisions about inventory management, resource allocation, and supply chain optimization, ultimately driving down costs and enhancing profitability.

Case Study: The Success Story of Chateng Textile Factory

The Chateng Textile Factory's success story is a testament to the power of collaboration and innovation. In 2018, the factory partnered with leading universities and research institutions to develop a new generation of eco-friendly dyes. This partnership not only accelerated the development of these technologies but also allowed the factory to gain insights into new materials and processes that could further enhance its sustainability efforts.

As a result, the Chateng Textile Factory became a pioneer in the field of eco-friendly textile production. Its products have won numerous awards for their innovative design and environmental friendliness, positioning the factory as a leader in sustainable fashion.

Conclusion: Craftsmanship Reinvented for the Digital Age

The Chateng Textile Factory workshop is not just a place where textiles are made; it is a hub of creativity and innovation. With its dedication to sustainable practices and technological advancements, the factory has set a standard for excellence in the textile industry. As we move forward into an increasingly digital age, it is clear that the Chateng Textile Factory will continue to play a crucial role in shaping the future of textile production.

In conclusion, the Chateng Textile Factory workshop stands as a testament to the power of human ingenuity and dedication. Through its commitment to craftsmanship, technological innovation, and sustainability, it has become a model for other industries looking to achieve similar levels of excellence. As we look towards the future, it is clear that the Chateng Textile Factory will continue to be a source of inspiration and innovation in the world of textile production.

背景介绍

聊城纺织厂车间是一个充满活力与创新的场所,其生产流程和技术水平在当地乃至全国都有很高的声誉,工人们精心操作着各种纺织机械,生产出高质量的纺织品。

车间内部设施与工作流程

设备设施

车间内部配备了先进的纺织机械和自动化生产线,包括但不限于织布机、染整设备、熨烫设备等,这些设备不仅保证了生产的效率和质量,还大大提高了生产过程的环保性和安全性。

工作流程

在聊城纺织厂车间,工作流程主要分为以下几个步骤:原料准备、织布、染色、印花、整理和成品检验,每个步骤都有严格的操作规程和质量控制标准,以确保最终产品的质量和一致性。

车间管理与员工培训

车间管理

聊城纺织厂车间实行严格的现场管理,包括生产计划的制定、生产过程的监控和调整、员工培训等,车间管理人员通过不断优化生产流程和提高员工技能,确保了生产的稳定性和高效性。

员工培训

为了确保员工的技能水平和产品质量,聊城纺织厂车间定期开展员工培训,培训内容包括但不限于纺织工艺、设备操作、安全生产等方面的知识,车间还为员工提供各种学习资源和机会,以帮助他们不断提高自己的技能水平。

案例分析

为了更好地说明聊城纺织厂车间的生产流程和技术水平,我们可以引入一个英文案例。

英文案例:某纺织厂在聊城地区以其先进的生产技术和高效的运营模式而闻名,该厂的车间采用了先进的纺织机械和自动化生产线,实现了高效的生产和环保生产,该厂还注重员工的培训和技能提升,为员工提供了各种学习资源和机会,以帮助他们不断提高自己的技能水平,该厂还注重生产过程的监控和调整,通过不断优化生产流程和提高员工技能,确保了生产的稳定性和高效性。

聊城纺织厂车间是一个充满活力与创新的场所,其生产流程和技术水平在当地乃至全国都有很高的声誉,工人们精心操作着各种纺织机械,通过严格的生产流程和技术管理,生产出高质量的纺织品,该车间注重员工的培训和技能提升,为员工提供了各种学习资源和机会,以帮助他们不断提高自己的技能水平,该厂还注重环保和安全生产,为企业的可持续发展奠定了坚实的基础。

Articles related to the knowledge points of this article:

The Story of Textile Mills Line Bars

A Comprehensive Guide to Joachim Weaving Factory