The Art of Transfer Printing:A Comprehensive Guide to Fabric Textile Transfer

Transfer printing, also known as screen printing, is a popular method of applying designs onto fabrics. This technique involves using a mesh screen to transfer ink or paint from a stencil onto the fabric surface. In this guide, we will explore the art of transfer printing and provide a comprehensive overview of the process.,The first step in transfer printing is selecting the right design for your fabric. You can either create your own design or use pre-made templates. Once you have your design, you will need to prepare your fabric by washing it and drying it thoroughly. Next, you will need to apply a layer of transfer paper to the back of the fabric. This will help prevent the design from bleeding through when the screen is applied.,Next, you will need to apply a layer of ink or paint to the screen. This will depend on the type of design you are creating and the material you are using. Once the screen is ready, you will need to apply it to the fabric. This can be done by hand or with a machine. The screen should be pressed firmly onto the fabric, but not too tightly.,Finally, you will need to remove the screen and wash the fabric thoroughly. This will allow the design to come off and reveal the original fabric underneath. With practice, you can master the art of transfer printing and create beautiful designs on any type of fabric.

Introduction

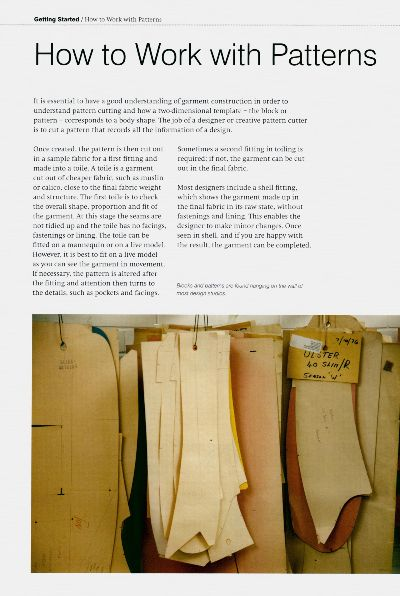

In the realm of textile design and production, transfer printing stands as a testament to the ingenuity and precision of human creativity. This process involves using a pattern or design onto a transfer material (usually a plastic sheet) and then applying that pattern to fabric, resulting in a precise replication of the design. From fashion labels to home decor, transfer printing is a versatile technique that can transform even the most mundane textiles into works of art. In this guide, we'll explore the intricacies of transfer printing, from the basics to advanced techniques, and provide practical tips for both beginners and professionals alike.

Basics of Transfer Printing

-

Transfer Materials:

- Transfer Paper: A thin, translucent sheet coated with a photosensitive material that allows the design to be transferred onto the fabric.

- Transfer Cloth: A soft, absorbent cloth used to apply the transfer paper to the fabric surface.

- Transfer Brushes: Fine brushes made of synthetic fibers designed to apply the transfer paper evenly and smoothly.

- Heat Gun: An appliance that uses heat to activate the transfer paper, making it easier to remove once the design has been transferred onto the fabric.

-

Design Preparation:

- Choose a design that is scalable and suitable for transfer printing.

- Use a vector graphics editor like Adobe Illustrator or Inkscape to create the design.

- Ensure the design is high-resolution and editable for easy adjustments.

-

Application Techniques:

- Apply the transfer paper to the transfer cloth, ensuring a smooth and even application.

- Use a transfer brush to gently spread the design across the cloth, avoiding overlapping areas.

- If necessary, use a heat gun to activate the transfer paper, allowing it to adhere better to the fabric.

Advanced Techniques

-

Digital Transfer:

- This technique involves using a computer-generated digital image to produce the transfer paper.

- Benefits: High-quality designs, customizable sizes, and reduced waste due to fewer materials needed.

- Example: The popular "Fashionista" line by Ralph Lauren uses digital transfer to create its iconic logos and patterns.

-

Embossed Transfer:

- Creates a raised, textured effect on the fabric when the design is transferred.

- Benefits: Adds visual interest and depth to the final product.

- Example: Gucci's signature embossed leather bags are often printed using this technique.

-

UV Stamping:

- Uses ultraviolet light to permanently bond the design onto the fabric.

- Benefits: Long-lasting results and minimal fading over time.

- Example: Louis Vuitton's monogrammed luggage frequently employs UV stamping for their signature designs.

Case Study: Nike Air Zoom Pegasus 38

Nike, a sportswear giant, has mastered the art of transfer printing through its iconic Air Zoom Pegasus 38 shoe. The design features a unique pattern inspired by the wings of a Pegasus bird, which was initially created using traditional screen printing techniques. However, Nike recognized the potential of transfer printing and decided to invest in digital technology to produce high-quality transfer papers for mass production.

The company developed a proprietary software system that allowed them to quickly and easily design and print their logos and other important elements onto transfer paper. This not only streamlined the design process but also ensured consistency across all products, from sneakers to apparel. By utilizing transfer printing, Nike was able to maintain its brand identity while also offering consumers a range of stylish and functional footwear options.

Conclusion

Transfer printing is more than just a technique; it's a powerful tool for artists and designers alike. With its ability to transform even the most ordinary textiles into works of art, transfer printing continues to captivate audiences around the world. Whether you're a seasoned professional or simply an enthusiast, there's always something new to learn and discover in this fascinating field. So why not give it a try yourself? You might be surprised at how much your next project could benefit from the magic of transfer printing.

布料纺织品移印简介

布料纺织品移印是一种精细的工艺技术,通过特殊的印刷方法将图案转移到布料上,它不仅提高了产品的美观度,还赋予了产品独特的个性,在当今快节奏的现代生活中,移印技术因其高精度、高效率的特点,受到了广泛的应用。

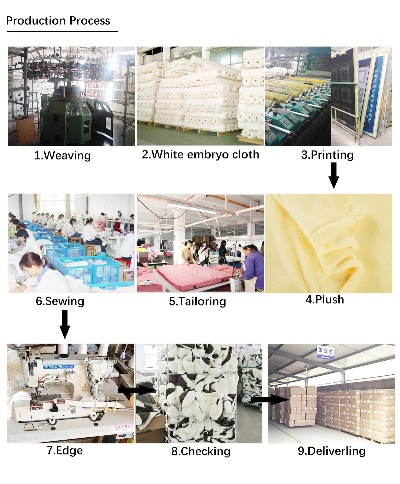

移印工艺流程

- 材料准备:选择高质量的布料和印花材料,确保图案的清晰度和颜色饱和度。

- 设计图案:设计师根据产品需求和客户要求,设计出所需的图案。

- 印刷操作:使用专业的移印设备,将图案转移到布料上,这个过程需要精确控制温度、压力和时间等参数。

- 检查质量:移印完成后,需要进行严格的检查,确保图案的完整性和质量。

案例分析

以纺织品为例,展示移印工艺的应用实例。

【案例一】高质量纺织品移印

某品牌的新款服装面料采用了高质量的布料和印花材料,经过精细的设计和移印工艺处理,使得服装整体看起来更加高档、时尚,移印过程中,严格控制温度、压力和时间等参数,确保图案的完整性和质量,最终的产品不仅美观度极高,还具有独特的个性。

【案例二】环保材料移印

近年来,随着环保意识的提高,越来越多的企业开始使用环保材料进行移印,这种工艺不仅可以提高产品的美观度,还可以减少对环境的污染,使用可降解的印花材料和环保型移印设备,使得产品在环保的同时也具有时尚感。

移印工艺特点

- 高精度:移印技术能够精确控制图案的形状、大小和颜色,使得产品具有极高的美观度。

- 高效率:移印工艺具有高效率的特点,能够快速完成大量的产品生产。

- 多样化:移印工艺可以应用于各种不同材质和图案的产品上,满足不同客户的需求。

- 环保性:使用环保材料进行移印,符合现代社会的环保要求。

英文表格补充说明(可选)

表格1:移印工艺参数对照表

| 参数名称 | 数值范围 | 描述 |

|---|---|---|

| 温度范围 | 根据布料和印花材料选择 | 控制印花材料在特定温度下的固化时间 |

| 压力范围 | 根据布料和印花材料选择 | 控制印花过程中所需的压力大小 |

| 时间范围 | 根据图案复杂度和布料厚度选择 | 控制印花过程中的时间长度 |

布料纺织品移印是一种精细的工艺技术,它不仅提高了产品的美观度,还赋予了产品独特的个性,在当今快节奏的现代生活中,移印技术因其高精度、高效率的特点,受到了广泛的应用,通过精细的设计和移印工艺处理,可以创造出各种不同材质和图案的产品,满足不同客户的需求,使用环保材料进行移印,符合现代社会的环保要求。

Articles related to the knowledge points of this article:

Chinas Textile Market Overview and Recent Trends

Top Picks for Shanghai Home Textile Essentials

The Ugandan Textile Market A Global Perspective and Regional Insights

The Ultimate Guide to Choosing the Best Fabrics for Your Next Project

Unveiling the Fabric of Success:A Strategic Guide for Textile Enterprises

Exploring the Art of Salt Texture in Home Textiles:An Idealized Journey