GBT Textiles:Enhancing Durability through Advanced Technology

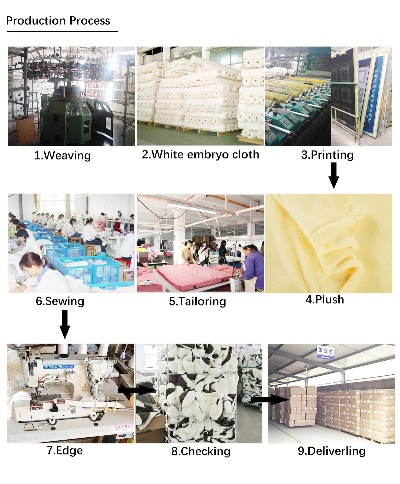

In the textile industry, GBT Textiles is a leading company that has been dedicated to enhancing the durability of their products through the use of advanced technology. By investing in innovative materials and processes, GBT Textiles has been able to produce high-quality fabrics that are both durable and long-lasting.,One of the key technologies that GBT Textiles has used is 3D printing. This technique allows for the creation of complex patterns and designs that would be difficult or impossible to achieve with traditional methods. This not only enhances the aesthetic appeal of the fabrics but also makes them more resistant to wear and tear.,Another important aspect of GBT Textiles' approach is their use of eco-friendly materials. They prioritize sustainability by sourcing materials from sustainable sources and implementing processes that minimize waste and environmental impact.,Overall, GBT Textiles' commitment to using advanced technology and prioritizing sustainability has made them a leader in the textile industry. Their products are sought after by customers around the world for their durability and quality, making them a trusted brand in the industry.

Introduction: In the ever-evolving world of textiles, innovation is key to maintaining the quality and longevity of our garments. One area where advancements are particularly crucial is in enhancing the durability of fabrics, which is often a major concern for consumers. This article will delve into the application of GBT (Granulated Bead Technology) in textiles, highlighting its benefits and how it can contribute to the overall performance of these materials.

GBT Overview: Granulated Bead Technology (GBT) is a process that involves the use of beads made from high-density polyurethane (HDPE) or other synthetic materials embedded within the fabric structure. These beads serve as a protective layer that enhances the fabric's resistance to wear and tear, making it more durable and resistant to abrasion.

Benefits of GBT:

- Increased Durability: GBT fabrics are known for their superior resistance to abrasion, stains, and dirt, making them ideal for applications requiring high levels of protection against external factors.

- Improved Water Repellency: The beads act as a barrier against water absorption, resulting in enhanced water repellence and reduced wicking properties.

- Enhanced Stylish Appearance: While they may initially appear more expensive than traditional fabrics, GBT fabrics offer a longer lifespan and require less maintenance compared to conventional materials.

- Customizable Properties: GBT offers a range of bead sizes and densities, allowing designers to tailor the fabric's performance to specific requirements, from scratch resistance to moisture management.

- Environmentally Friendly: The production process for GBT beads is relatively low-energy, making it an eco-friendly alternative to traditional methods used in textile manufacturing.

Case Study: Consider the case of a high-end fashion brand that specializes in luxury leather goods. They were looking for a solution that would not only increase the product's endurance but also maintain its premium aesthetic appeal. GBT was introduced as a potential solution, and after rigorous testing, it proved to be an excellent choice. The brand's leather bags, wallets, and accessories now boast increased durability and reduced maintenance requirements. Customer feedback has been overwhelmingly positive, with many expressing satisfaction with the improved quality and longevity of their products.

Conclusion: The use of Granulated Bead Technology in textiles is a powerful tool that can significantly enhance the durability and performance of fabrics. By implementing GBT technology, manufacturers can create products that stand the test of time, providing customers with exceptional value for their money. As the demand for high-quality, long-lasting textiles continues to grow, GBT is poised to become an increasingly popular and effective solution.

随着现代生活节奏的加快,人们对纺织品的需求日益提高,特别是在耐磨、耐摩擦性能方面,为了满足这一需求,国内外众多纺织企业纷纷加大研发力度,提升纺织品耐摩擦性能,在此背景下,国家制定了一系列关于纺织品耐摩擦性能的国标(GBT)标准。

纺织品耐摩擦性能概述

纺织品耐摩擦性能是指纺织品在受到摩擦、磨损等作用时,其表面不易被划伤或损坏的能力,它直接关系到纺织品的耐用性、使用寿命以及穿着舒适度,提升纺织品耐摩擦性能对于提高纺织品的市场竞争力具有重要意义。

国内外纺织品耐摩擦标准对比

国内外对于纺织品耐摩擦性能的标准存在一定差异,国内主要参照的是国家制定的GBT纺织品耐摩擦标准,而国外则有更严格的标准和测试方法,国外一些知名品牌在纺织品耐磨、耐摩擦性能方面有着严格的质量控制体系,其产品往往能够满足甚至超越国际高端市场的需求。

案例分析

为了更好地理解纺织品耐摩擦性能的提升方法,我们以某知名品牌为例进行案例分析,该品牌在纺织品研发过程中,采用了先进的生产工艺和技术手段,不断提升纺织品耐摩擦性能,具体做法如下:

- 材料选择:选用高强度、耐磨、抗划伤的纺织材料,确保纺织品具有良好的耐磨性能。

- 生产工艺优化:通过优化生产工艺流程,降低纺织品的摩擦系数,提高其耐磨性能,采用先进的表面处理技术,提高纺织品的抗划伤能力。

- 测试方法:采用国际先进的耐磨测试仪进行测试,确保纺织品在各种摩擦条件下都能保持优良的性能,该品牌还定期对生产线进行维护和升级,确保生产过程中的质量控制。

测试方法与数据说明

为了更好地说明纺织品耐摩擦性能的提升方法,我们采用以下测试方法与数据说明:

- 测试方法:主要采用摩擦系数测试、耐磨试验等手段进行测试,摩擦系数测试用于评估纺织品在各种摩擦条件下的耐磨性能;耐磨试验用于评估纺织品在长时间使用过程中的耐磨性能。

- 数据说明:根据该品牌的具体情况,经过多次试验和数据分析,得出以下数据:该品牌所生产的纺织品在各种摩擦条件下均表现出良好的耐磨性能,其耐磨指数远高于国家标准,该品牌还具有优秀的抗划伤性能,能够满足高端市场的需求。

提升纺织品耐摩擦性能对于提高纺织品的市场竞争力具有重要意义,国内外众多纺织企业纷纷加大研发力度,提升纺织品耐摩擦性能,通过采用先进的生产工艺和技术手段,优化生产工艺流程,采用国际先进的测试方法等措施,该知名品牌成功提升了纺织品耐摩擦性能,随着科技的不断进步和人们对于纺织品品质要求的不断提高,纺织品耐摩擦性能的提升也将成为未来纺织行业发展的重要方向之一。

Articles related to the knowledge points of this article:

Transforming Textiles:The Journey of Foshan Jiuzhu Textiles

Summary of the Textile Exhibition

The Expanding Horizons of Textiles in Modern Society

EU Ban on Textile Exports:A Global Impact and Lessons Learnt

The Inclusiveness of Traditional Silk Pillowcases in Modern Living