The Standards for Dyeing Textiles Production

: Dyeing Textiles Production Standards,Abstract:,This paper discusses the standards for dyeing textiles production, which are essential for ensuring the quality of the final product. The standards cover aspects such as dye selection, concentration, temperature, time, and pH adjustment during the dyeing process. Additionally, proper handling and storage of dye solutions are crucial to prevent contamination and maintain the color consistency. The standards also emphasize the need for regular maintenance of equipment and adherence to safety protocols to minimize risks associated with dyeing processes. Overall, these standards ensure that textiles produced meet consumer expectations and are safe for use in various applications.

Introduction: In the world of textile production, dyeing is a crucial step that not only determines the color and pattern of the final product but also affects its durability and environmental impact. Therefore, it is essential to have clear and stringent standards for the dyeing process to ensure quality control and consumer satisfaction. This guide will provide an overview of the key standards for dyeing textiles, including the selection of dyes, temperature and pH adjustment, dyeing time, and post-dyeing treatments. We'll also discuss some best practices and common challenges encountered in the dyeing process.

Selection of Dyes: The choice of dyes plays a significant role in determining the final color and performance of the textile. Here are some factors to consider when selecting dyes:

- Colorfastness: The dye should be able to withstand washing, sunlight, and other environmental factors without fading or discoloration.

- Environmental Impact: It's important to choose dyes that are eco-friendly and biodegradable, reducing the risk of pollution and harmful chemicals.

- Durability: The dye should be resistant to wear and tear, ensuring that the textile can withstand heavy use and repeated washing.

- Texture: The texture of the textile should be compatible with the dye, avoiding any adverse effects on the fabric's appearance or performance.

- Price: While cost should not be the sole factor in choosing dyes, it's important to balance cost with quality and sustainability.

Temperature and pH Adjustment: The temperature and pH level of the dye bath play a crucial role in achieving the desired color and preventing undesired reactions. Here are some guidelines:

- Temperature: The dye bath should be heated to the correct temperature based on the type of dye and fabric. For example, acid dyes require a lower temperature than reactive dyes.

- pH Level: The pH level of the bath should be adjusted to the optimal range for the selected dye. For example, acid dyes work best at pH 3-4, while reactive dyes work best at pH 9-10.

Dyeing Time: The duration of the dyeing process is critical for achieving the desired color intensity and uniformity. Here are some guidelines:

- Initial Dyeing Time: The initial dyeing time should be sufficient to allow the dye to penetrate the fabric fibers. Generally, this is between 15-30 minutes for most dyes.

- Final Dyeing Time: The final dyeing time should be longer to ensure full coverage and even color distribution across the fabric. This may vary depending on the specific dye and fabric type.

Post-Dyeing Treatments: Once the dye has been applied, it's important to perform post-dyeing treatments to enhance the color strength and stability of the textile. These treatments may include:

- Washing: After dyeing, the textile should be washed to remove any excess dye or impurities.

- Bleaching: Some textiles may benefit from a gentle bleaching process to improve their appearance and reduce fading over time.

- Heat treatment: Heating the textile in a steam or hot water bath can help set the dye and improve its resistance to wear and tear.

Best Practices: To achieve high-quality dyed textiles, there are several best practices to follow:

- Proper Material Handling: Ensure that the fabric is properly handled during the dyeing process to avoid damage or contamination.

- Quality Control: Regularly inspect the dyed textiles for defects such as color variation, bleeding, or poor adhesion.

- Waste Management: Consider implementing recycling or disposal methods to minimize the environmental impact of the dyeing process.

Common Challenges: Despite the importance of these standards, many challenges can arise during the dyeing process. Some common issues include:

- Inconsistent Dyestuff Performance: Different batches of dyestuff may produce varying results, leading to inconsistent color shades and patterns.

- Environmental Pollution: The dyeing process can release harmful chemicals into the environment, posing a threat to wildlife and human health.

- High Cost: High-quality dyes and specialized equipment can be expensive, making the process more expensive than traditional dyeing methods.

Conclusion: Dyeing textiles is a complex process that requires careful attention to detail. By following the standards outlined above, manufacturers can ensure that their products meet consumer expectations and meet environmental regulations. With proper knowledge and practice, dyers can produce high-quality textiles that stand out in today's competitive market.

随着纺织行业的快速发展,染色纺织品作为重要的纺织产品之一,其生产标准和质量要求越来越受到重视,本篇文章将围绕染色纺织品生产标准展开讨论,并结合实际案例进行分析。

染色纺织品生产标准概述

原料要求

染色纺织品的主要原料包括棉、麻、丝、毛等天然纤维,以及再生纤维等合成纤维,在生产过程中,必须符合国家相关标准和行业标准,确保原料的质量和安全性。

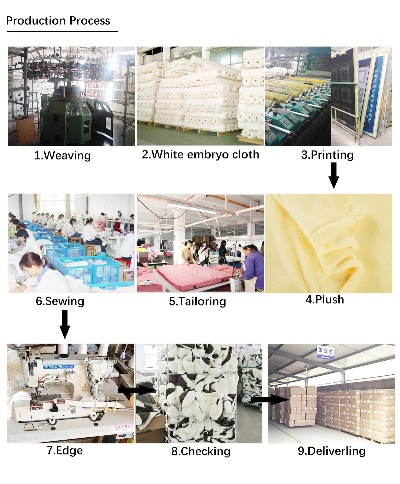

生产流程

染色纺织品的生产流程包括原料准备、染色、后整理、检验等多个环节,在每个环节中,都需要严格遵守相关标准和规范,确保产品质量和安全性。

生产标准的具体内容

(1)原料检验:对原料进行严格的检验,确保原料符合国家标准和行业标准。

(2)染色工艺:采用先进的染色技术,确保染色效果均匀、鲜艳、持久。

(3)后整理工艺:对染色纺织品进行必要的后整理,如柔软处理、防皱处理等,提高产品的舒适度和耐用性。

案例分析

以某知名纺织企业为例,该企业在染色纺织品生产过程中,严格按照国家标准和行业标准进行操作,确保产品质量和安全性,该企业在染色过程中采用了先进的染色技术,采用环保染料,确保染色效果均匀、鲜艳、持久,该企业还注重产品的舒适度和耐用性,对染色纺织品进行了必要的后整理处理,提高了产品的品质和附加值。

实际案例分析

在实际生产过程中,染色纺织品的质量和安全性受到多种因素的影响,如原料质量、染色工艺、后整理工艺等,为了确保染色纺织品的质量和安全性,在实际生产过程中,还需要注意以下几点:

-

原料采购:必须从正规渠道采购原料,确保原料的质量和安全性。

-

染色工艺控制:采用先进的染色技术,确保染色效果均匀、鲜艳、持久,还需要严格控制染料的质量和浓度,避免对环境造成污染。

-

后整理工艺控制:对染色纺织品进行必要的后整理处理,如柔软处理、防皱处理等,提高产品的舒适度和耐用性,还需要注意产品的环保性,采用环保材料和工艺。

染色纺织品生产标准是保证产品质量和安全性的重要保障,在实际生产过程中,必须严格按照国家标准和行业标准进行操作,确保产品质量和安全性,还需要注重产品的环保性、舒适度和耐用性等方面,提高产品的附加值和市场竞争力。

Articles related to the knowledge points of this article:

An Overview of the United States Textile Tariff Rates

A Profile of PJSH Textiles The Fabric of Modern Elegance

The 11th Floor of Xining Textiles:A Global Tapestry

The Fabric of Education:Defining the Materiality of School Bags