The Fabric of a Green Future:Exploring Textile Recycling Technology

"The Fabric of a Green Future: Exploring Textile Recycling Technology",In the pursuit of sustainable development, textile recycling technology has emerged as an essential component of a green future. This innovative process involves the conversion of used textiles into new products, reducing waste and conserving resources. By leveraging advanced technologies such as mechanical recycling, chemical treatment, and biodegradation, textile recycling not only minimizes environmental impact but also enhances economic viability. As consumers, we can play a crucial role in promoting this practice by choosing eco-friendly clothing and accessories made from recycled materials. By embracing textile recycling technology, we can contribute to a more sustainable and equitable world where resources are conserved and waste is minimized.

Introduction: In the tapestry of our modern world, textiles are an integral part of our lives. From the soft comfort of our clothes to the durability of our furniture, textiles play a significant role in shaping our environment and economy. However, with the exponential growth of textile production, the demand for new fabrics has led to a growing textile waste problem. This issue is not just environmentally harmful but also economically burdensome. Therefore, it is crucial to explore innovative textile recycling technologies that can turn this waste into something valuable again. In this article, we will discuss some of the latest advancements in textile recycling technology and how they can help us achieve a greener future.

Textile Recycling Technologies:

-

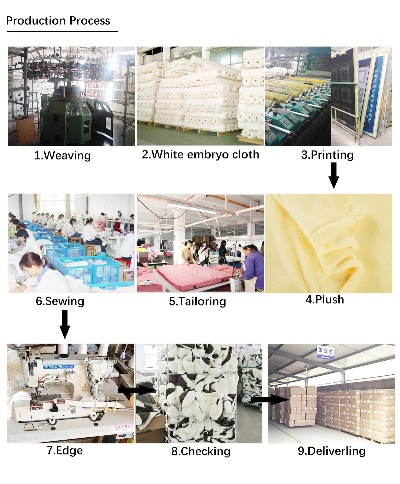

Recycled Fiber Production: Recycled fiber production involves converting waste textiles into new materials. This process involves mechanical separation, chemical treatment, and melt spinning techniques. The separated fibers are then processed into yarns or fabrics using conventional spinning methods. Some examples of recycled fiber products include carpets, upholstery, and even clothing. These products are often made from recycled polyester, cotton, and other synthetic materials.

-

Textile Regeneration: Textile regeneration involves using old textiles as raw materials for making new ones. This process involves cutting and shredding the old fabrics, blending them with new materials, and then knitting or sewing them together. The resulting product is usually lighter and more durable than traditional textiles. Some examples of textile regenerated products include rugs, curtains, and even clothing.

-

Textile Composting: Textile composting involves turning waste textiles into nutrient-rich soil by combining them with organic matter. This process helps to reduce landfill waste and promote sustainable agriculture. Some examples of textile composting include textile scraps used for garden beds and potted plants.

-

Textile Energy Recovery: Textile energy recovery involves using waste textiles as fuel for power generation. This process involves breaking down the fabric into its constituent fibers using mechanical methods and then burning them to produce electricity. Some examples of textile energy recovery include textile waste being used as fuel for power plants and industrial facilities.

Case Study: One example of successful textile recycling is the use of recycled polyester in the production of carpets. In the United States, there is a company called Carpet Solutions that specializes in producing carpets from recycled polyester. The company's mission is to reduce the amount of textile waste in landfills and promote sustainability in the fashion industry. By using recycled polyester, Carpet Solutions is able to create carpets that are both eco-friendly and stylish.

Conclusion: Textile recycling technology has emerged as a powerful tool in combating the textile waste crisis. By exploring innovative methods of textile recycling, we can turn waste into value and contribute to a greener future. As we continue to embrace sustainable practices in our daily lives, it is important to support these efforts by investing in innovative textile recycling technologies. After all, the fabric of our future depends on the choices we make today.

纺织品循环利用设备概述

随着环保意识的日益增强,纺织品循环利用设备在环境保护和资源循环利用方面发挥着越来越重要的作用,这些设备能够有效地处理和再利用废旧纺织品,减少环境污染,降低资源浪费,本文将详细介绍纺织品循环利用设备的相关知识,包括其工作原理、类型、应用场景以及案例分析。

纺织品循环利用设备的工作原理

纺织品循环利用设备主要通过物理、化学或生物方法对废旧纺织品进行回收处理,这些设备通常包括预处理系统、分离系统、再生纤维生产系统等,预处理系统可以对废旧纺织品进行初步的清洗、分类和整理,分离系统则通过物理或化学方法将废旧纺织品中的有用物质和无用物质进行分离,再生纤维生产系统则用于生产再生纤维制品。

纺织品循环利用设备类型

- 机械式回收设备:这是一种常见的纺织品循环利用设备类型,通过机械力对废旧纺织品进行破碎、筛分等处理,这种设备的优点是操作简单、效率高,适用于大规模的废旧纺织品回收处理。

- 生物降解材料生产设备:这种设备主要用于生产生物降解材料,如生物降解纤维、生物降解塑料等,通过生物技术手段,将废旧纺织品转化为可降解的材料,减少对环境的污染。

- 智能回收系统:随着物联网技术的发展,一些先进的纺织品循环利用设备开始引入智能回收系统,通过传感器、物联网等技术手段实现废旧纺织品的自动识别、分类和回收处理。

纺织品循环利用设备的应用场景

- 家庭垃圾分类:在家庭垃圾分类中,纺织品循环利用设备可以用于对废旧纺织品进行分类和处理,通过这些设备,居民可以将可回收的废旧纺织品进行回收再利用,减少对环境的污染。

- 工业生产中的废旧纺织品回收:在工业生产过程中,废旧纺织品回收是不可避免的环节,这些设备可以用于对工业生产过程中的废旧纺织品进行回收和处理,减少对资源的浪费。

- 公共设施建设:在公共设施建设中,纺织品循环利用设备也可以发挥重要作用,公共设施中的座椅套、地毯等纺织品可以通过这些设备进行再利用,减少对环境的污染。

案例分析

以下是某地区纺织品循环利用设备的案例分析:

某地区近年来大力发展纺织品的循环利用工作,引入了多种纺织品循环利用设备,其中一种机械式回收设备的案例如下:

该机械式回收设备采用了先进的机械破碎技术,能够高效地处理大规模的废旧纺织品,该设备配备了传感器和物联网技术,能够实现废旧纺织品的自动识别和分类,该设备还配备了先进的再生纤维生产系统,能够生产出高质量的再生纤维制品,通过该设备的运行,该地区废旧纺织品的回收率得到了显著提高,有效地减少了环境污染。

纺织品循环利用设备在环境保护和资源循环利用方面发挥着越来越重要的作用,随着技术的不断进步和人们环保意识的提高,纺织品循环利用设备的种类和功能也在不断丰富和完善,我们应继续关注纺织品循环利用设备的研发和应用,为环境保护和资源循环利用做出更大的贡献。

Articles related to the knowledge points of this article:

Boosting Your Wardrobe with Bonizys Wide Range of Textiles

Exploring the Dynamic Landmarks of Jinjiang Tianyue Textiles

The Evolution and Impact of Hengxingli Textiles

The Fabric of Luxury:An In-depth Look at Shangbo Hotel Textiles