纺织品颜料修改规范标准

This paper discusses the standards for modifying textile dyes. The standards include the color, brightness and shade of the dyed fabrics, the quality of the dyed fabrics, the stability of the dyed fabrics, and the safety of the dyed fabrics. The standards are based on the international standard ISO 12645-1:2013 "Dyeing - General requirements". The standards also include the requirements for the dyeing process, such as temperature, pH, time and concentration of the dye solution. The standards also include the requirements for the finishing process, such as drying and finishing agents. The standards are designed to ensure that the dyed fabrics meet the required quality and safety standards, and to provide a basis for the development of new dyeing technologies.

Introduction: The textile industry is one of the most crucial industries in the world, producing a wide range of products that are used in daily life. One of the essential aspects of this industry is the use of dyes and pigments to color these products. However, due to various reasons such as environmental concerns, consumer preferences, and economic factors, there is a need for stricter regulations on the use and disposal of these materials. This paper will discuss the current standards for modifying textile colors, including the use of eco-friendly dyes, the importance of proper disposal methods, and the challenges faced by manufacturers in meeting these standards.

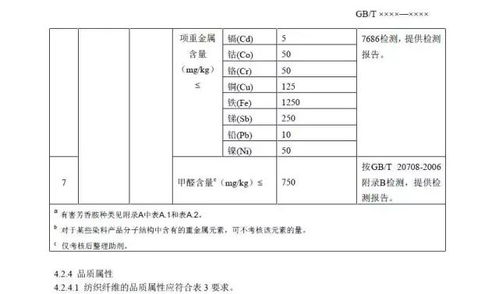

Current Standards: There are several international and national standards that regulate the use and disposal of textile colors. Some of the main ones include:

-

International Organization for Standardization (ISO) 20746 This standard sets out the requirements for the safe use and disposal of dyestuffs and other colourants used in the textile industry. It covers issues such as toxicity, stability, and biodegradability.

-

European Union Regulation (EU) No 1234/2013 This regulation establishes maximum levels of toxic substances that can be present in textiles. It also requires manufacturers to take measures to reduce the use of harmful chemicals in their dyes and pigments.

-

United States Environmental Protection Agency (EPA) Guidelines These guidelines provide guidance on the safe use and disposal of dyes and pigments in the textile industry. They cover issues such as exposure limits, waste management, and recycling.

-

National Standards in China China has its own set of standards for the use and disposal of textile dyes and pigments. These standards are designed to ensure compliance with international standards while also addressing local environmental concerns.

-

Globally Harmonized System (GHS) The GHS is a comprehensive guide to the health effects of chemicals. It provides information on the potential risks associated with certain dyes and pigments, including their exposure levels and routes of exposure.

Importance of Eco-Friendly Dyes: The use of eco-friendly dyes is becoming increasingly important as consumers become more aware of the environmental impact of their purchases. Eco-friendly dyes are derived from renewable sources such as plant-based dyes or recycled water. They are often less toxic and have lower levels of heavy metals than conventional dyes.

Proper Disposal Methods: Manufacturers must follow proper disposal methods for their dyes and pigments to minimize their impact on the environment. This includes using appropriate containers and labeling them properly to prevent accidental spills. They should also take steps to ensure that the dyes and pigments are disposed of safely and legally.

Challenges Faced by Manufacturers: One of the biggest challenges faced by manufacturers is meeting the strict standards set by international organizations. This requires ongoing research and development to develop new dyes and pigments that meet these standards while also being cost-effective. Additionally, manufacturers must also comply with local regulations and policies, which can add additional complexity to their operations.

Case Study: Let's take a look at a case study involving a textile manufacturer in China who was struggling to meet the EU's 1234/2013 regulation. The company had been using traditional dyes that were known to cause skin irritation and respiratory problems among workers. In response, the company decided to invest in eco-friendly dyes and developed a new formula that met all the required standards. The new formula was tested extensively before being released to the market. The results were encouraging, and the company was able to increase its market share while also reducing its environmental footprint.

Conclusion: In conclusion, textile manufacturers must adhere to strict regulations when it comes to the use and disposal of dyes and pigments. By following the latest international and national standards, they can ensure that their products are safe for consumers and contribute to a healthier environment. The adoption of eco-friendly dyes is also becoming increasingly important as consumers become more aware of the impact of their purchases. Manufacturers must continue to innovate and invest in new technologies to meet these demands while also complying with legal requirements.

随着纺织品的广泛应用,颜料在纺织品中的使用也日益增多,为了确保纺织品颜料的正确使用和修改,制定纺织品颜料修改规范标准显得尤为重要,本篇文章将详细介绍纺织品颜料修改规范标准的相关内容,并结合实际案例进行说明。

纺织品颜料修改规范标准概述

定义与背景

纺织品颜料修改规范标准是对纺织品颜料使用过程中的一系列规定和要求,它旨在确保颜料的使用符合纺织品的特性、性能和安全要求,同时保证修改后的纺织品符合相关标准和法规。

修改规范标准内容

(1)颜料种类与性能要求

颜料种类繁多,其性能和质量直接影响到纺织品的使用效果,修改规范标准应明确规定颜料的种类、颜色、光泽、耐水洗性、耐热性等性能指标。

(2)颜料使用范围与限制

颜料的使用范围应符合纺织品的特性,避免使用不当导致纺织品性能下降或损坏,还应明确颜料的使用限制,如使用限量、使用环境等。

(3)修改过程与注意事项

修改纺织品颜料时,应遵循一定的修改流程和注意事项,应确保颜料的质量符合要求;在修改过程中应遵循安全、环保的原则;修改后的纺织品应进行必要的检测和评估,确保其符合相关标准和法规。

实际案例说明

以某纺织品公司为例,其生产的纺织品在使用颜料过程中存在一些问题,为了解决这些问题,该公司制定了相应的修改规范标准,并采取了以下措施:

明确颜料种类与性能要求

该公司明确了需要使用的颜料的种类和性能要求,以确保其纺织品在使用过程中符合相关标准和法规,还明确了颜料的颜色、光泽、耐水洗性等性能指标,以满足不同客户的需求。

严格颜料使用范围与限制

该公司严格控制颜料的使用范围和限制,避免使用不当导致纺织品性能下降或损坏,还制定了相应的使用管理办法和操作规程,以确保颜料的正确使用和修改。

实施修改过程与注意事项

在该公司的修改过程中,首先对颜料进行了质量检测和评估,确保其符合要求,然后按照修改流程和注意事项进行修改,并在修改过程中遵循安全、环保的原则,对修改后的纺织品进行了必要的检测和评估,确保其符合相关标准和法规。

英文表格补充说明

以下是纺织品颜料修改规范标准的英文表格补充说明:

| 项目 | 描述 | 示例数据 |

|---|---|---|

| 颜料种类与性能要求 | 颜色、光泽、耐水洗性等 | 根据实际需求制定具体指标 |

| 使用范围与限制 | 符合纺织品的特性 | 如适用于各种材质的纺织品 |

| 修改过程与注意事项 | 步骤流程 | 遵循安全、环保的原则 |

| 相关法规与标准 | 相关国家和地区的法规和标准 | 如ISO/IEC等 |

纺织品颜料修改规范标准是确保纺织品正确使用和修改的重要保障,通过制定相应的规范标准,可以确保颜料的使用符合纺织品的特性、性能和安全要求,同时保证修改后的纺织品符合相关标准和法规,在实际应用中,企业应结合自身实际情况制定相应的规范标准,并采取有效的措施进行实施和管理。

Articles related to the knowledge points of this article:

The Varied Landscape of Textile Consumption

The Testing of Textiles for Nucleic Acid

The Search for a Greener Future:Zero Formaldehyde Textiles