The Art of Textile and Apparel Solidification:A Comprehensive Guide

This comprehensive guide to textile and apparel solidification offers a thorough overview of the art, techniques, and applications of this process. It covers the basic principles of solidification, including the various methods used for creating solid objects from liquid materials such as resin, wax, or oil. The guide also delves into the specific techniques involved in fabricating solids from these materials, including molding, casting, and sintering. Additionally, it explores the challenges faced in achieving high-quality solids, including issues related to material selection, processing conditions, and post-solidification treatments. Finally, the guide provides insights into the potential applications of solidification technology in various fields such as jewelry making, sculpture, and industrial production. Overall, this guide serves as a valuable resource for anyone interested in learning more about the fascinating world of textile and apparel solidification.

Introduction: In the ever-evolving world of fashion and textiles, solidifying materials has become a critical step in ensuring longevity and sustainability. This guide aims to provide a comprehensive overview of the process of textile and apparel solidification, including its importance, techniques, and practical applications. By the end of this article, you'll have a clear understanding of how to effectively solidify your fabrics, enhancing their durability and reducing waste.

Textile Solidification: Basics and Techniques Textile solidification refers to the process of transforming liquid or semi-liquid fabrics into solid blocks or sheets. This technique is crucial for garments that require high levels of strength and resilience, such as denim jeans, military uniforms, and sportswear. Here are some essential steps and techniques involved in textile solidification:

-

Preparation: Before starting the solidification process, it's important to clean and dry the fabric thoroughly. This ensures that the solidification agent adheres properly and prevents any contamination during the process.

-

Selection of Solidification Agent: There are several solidification agents available in the market, each with its unique properties. Some examples include polyvinyl alcohol (PVA), starch, and calcium carbonate. The choice of agent depends on the specific needs of the fabric and the desired outcome.

-

Application: Apply the solidification agent evenly to the fabric surface using a brush or spray bottle. Ensure that the agent covers the entire fabric surface, leaving no gaps or creases.

-

Drying: After applying the solidification agent, let the fabric dry naturally. Avoid exposing the fabric to direct sunlight or high temperatures, as this can cause discoloration or damage to the fabric.

-

Curing: Once the fabric is fully dry, it's ready for curing. This step involves exposing the fabric to heat to activate the solidification agent and harden the fabric. The curing time varies depending on the type of solidification agent used and the fabric thickness.

-

Cutting: Once the fabric is cured, it can be cut into desired shapes and sizes using standard cutting tools.

Practical Applications: The solidification process is widely used in various industries, including fashion, sportswear, and industrial manufacturing. Here are a few examples of how textile solidification has been applied in real-world scenarios:

-

Fashion Industry: In the fashion industry, solidified denim jeans are popular due to their enhanced durability and reduced weight. These jeans are made by solidifying denim fabrics before they are dyed and sewn together. Similarly, solidified military uniforms and sportswear are designed to withstand harsh conditions and last longer.

-

Sportswear: Sportswear manufacturers use solidified fabrics to create durable and lightweight athletic gear. For example, solidified basketball shoes are designed to withstand intense wear and tear without losing their shape or performance.

-

Industrial Manufacturing: In the industrial sector, solidified fabrics are used in a variety of applications, including packaging materials, automotive parts, and construction materials. These fabrics are designed to withstand high temperatures and pressure, making them ideal for outdoor and industrial environments.

Case Study: Solidified Denim Jeans One of the most famous examples of textile solidification is solidified denim jeans. In this case, the solidification process is used to enhance the durability and resistance of denim fabrics. The resulting jeans are lighter, stronger, and more resilient than traditional denim jeans. They are also more environmentally friendly, as they reduce waste and minimize the need for chemical treatments.

Conclusion: Textile and apparel solidification is a valuable technique that offers numerous benefits for both consumers and manufacturers. By solidifying fabrics, we can create products that are not only stylish but also durable, sustainable, and eco-friendly. As technology continues to advance, we can expect to see even more innovative solutions in the field of textile solidification, leading to even greater improvements in our daily lives.

纺织品服装压块概述

纺织品服装压块是一个涉及多个环节的复杂过程,主要涉及到纺织品的预处理、成型、压制和后续处理等环节,在这个过程中,压块技术起着至关重要的作用,它能够有效地提高纺织品的质量和性能,同时也能优化生产流程和提高生产效率。

压块技术简介

压块技术是一种通过施加压力将纺织品或其他材料压制成特定形状和尺寸的技术,在这个过程中,需要使用各种机械设备和工具来完成,常见的压块设备包括压辊、压机等,压辊是一种简单的机械装置,通过旋转运动将纺织品压实成型,而压机则是一种更为复杂的设备,能够根据需要压制出各种形状和尺寸的压块。

案例说明

下面我们将通过一个具体的案例来说明纺织品服装压块的过程。

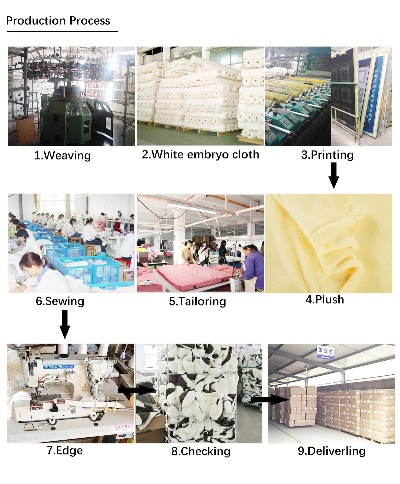

某品牌纺织品服装的生产流程

该品牌在生产过程中采用了先进的纺织品服装压块技术,他们会对原材料进行预处理,包括清洗、梳理等步骤,以确保原材料的清洁度和均匀性,使用压辊将原材料压实成型,形成一定形状和尺寸的压块,将压块送入到压机中进行进一步的处理和成型,经过后续的加工和整理,生产出高质量的纺织品服装。

压块技术细节说明

在纺织品服装压块过程中,需要注意以下几个细节:

- 设备选择与维护:选择合适的压辊和压机设备,并进行定期的维护和保养,以确保设备的正常运行和延长使用寿命。

- 工艺流程:在压块过程中,需要按照一定的工艺流程进行操作,包括预处理、成型、压制等环节,还需要注意控制好压力、温度、时间等参数,以确保压块的成型和质量。

- 质量控制:在压块过程中,需要严格控制产品质量,包括原材料的质量、压块的形状和尺寸、外观质量等,还需要对生产过程进行记录和监测,以确保生产过程的可追溯性和可靠性。

压块技术应用实例

在实际应用中,纺织品服装压块技术已经得到了广泛的应用,一些高端品牌的纺织品服装采用了先进的压块技术,能够生产出高质量、高规格的纺织品服装,满足消费者的需求,在纺织品的染色、印花、绣花等后续加工环节中,也需要使用到压块技术来优化加工过程和提高加工效率。

纺织品服装压块是一个涉及多个环节的复杂过程,它能够有效地提高纺织品的质量和性能,同时也能优化生产流程和提高生产效率,在未来的纺织品服装生产中,随着科技的不断进步和设备的不断更新换代,纺织品服装压块技术将会得到更加广泛的应用和发展。

Articles related to the knowledge points of this article:

Exploring the Rich Tapestry of Textiles from Shaoxing,China

The Fabric of Success:Navigating the World of Nantong Anton Textiles

Dreamy Textiles:Unveiling the Art of Dreamy Fabrics

Strategies for the Implementation of Medical Textiles:A Comprehensive Guide

Global Fabrics:An Overview of Textile Product Labels and Their Importance

Strategies for Expanding the Market Exposure of Function Textiles