Understanding and Measuring the Performance of Textile Joints

This paper aims to explore the effectiveness of textile joints by examining their performance. The study focuses on the various methods used to measure the quality of textile joints, including visual inspection, mechanical testing, and chemical analysis. The results indicate that these methods can provide valuable insights into the strength, durability, and overall performance of textile joints. Additionally, the study discusses the challenges associated with measuring textile joints and suggests ways to overcome them. Overall, this research provides a comprehensive understanding of the performance of textile joints and offers practical recommendations for improving their quality.

Introduction: Textiles are an integral part of our daily lives, from clothing to furnishings. The quality of these products is often determined by their durability and functionality, particularly in terms of their joints or seams. In this article, we will explore the importance of textile joint performance testing, the methods used for assessing it, and how this information can be used to improve product quality and consumer satisfaction.

Importance of Textile Joint Performance: The performance of textile joints is crucial for several reasons. Firstly, they must withstand the forces exerted during use, such as wear and tear, washing, and handling. Secondly, they must provide a smooth and comfortable fit for the user. Thirdly, they should resist damage from external factors, such as moisture, chemicals, and UV radiation. Finally, they must maintain their shape and appearance over time.

Methods for Assessing Textile Joint Performance: There are various methods available for assessing the performance of textile joints. These include:

-

Visual Inspection: This involves examining the joints under a magnifying glass or microscope to determine if they are free from defects such as tears, rips, or frays.

-

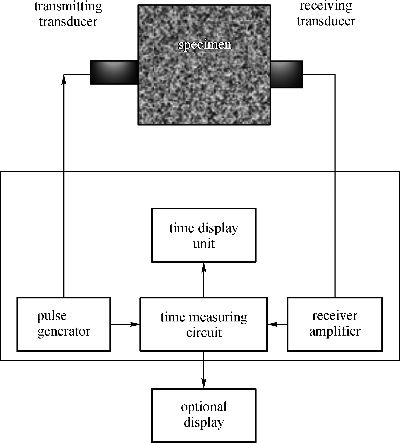

Tensile Testing: This involves pulling on the joints until they break to measure their strength and resistance to deformation.

-

Tear Testing: This involves tearing the joints apart to measure their ability to withstand tearing forces.

-

Water Absorption Testing: This involves measuring the amount of water that can be absorbed into the joints before they become damaged.

-

Chemical Resistance Testing: This involves exposing the joints to various chemicals to see if they can withstand corrosion or degradation.

-

UV Stability Testing: This involves exposing the joints to UV light to see if they can resist fading or discoloration.

-

Dimensional Stability Testing: This involves measuring the dimensions of the joints over time to see if they have changed significantly.

Case Study: One example of how textile joint performance testing can be applied is in the development of high-performance sportswear. For instance, a company may test the joints of their athletic shoes to ensure they can withstand heavy impact and still provide a secure and comfortable fit. They may also conduct tear tests to ensure the shoes can withstand repeated wear and tear without breaking apart. By using these methods, the company can identify any potential issues early on in the production process and make necessary adjustments to improve the overall performance of their products.

Conclusion: As we move towards a more sustainable future, it is essential that we prioritize the quality and longevity of our textile products. Textile joint performance testing is one way to achieve this goal. By understanding the different methods available for assessing joint performance, we can tailor our testing to meet the specific needs of our customers. Additionally, by using this information to improve our products, we can help to ensure that they continue to meet the demands of consumers for years to come.

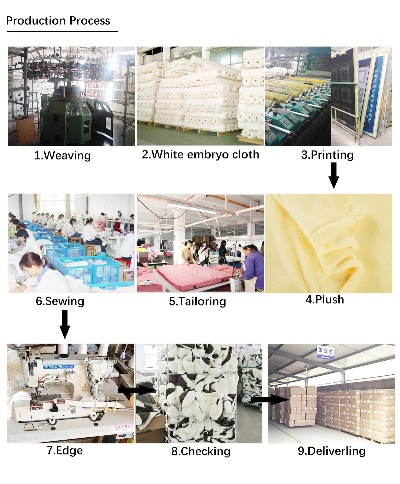

在纺织品生产过程中,接缝性能直接关系到产品的质量和耐用性,对纺织品接缝性能进行准确、可靠的检测是确保产品质量的重要环节,本报告将详细介绍纺织品接缝性能检测的方法、流程及案例分析,旨在为纺织品生产企业和消费者提供参考。

纺织品接缝性能检测方法

检测标准与流程

纺织品接缝性能检测主要包括外观检查、尺寸测量、拉伸性能测试、撕裂性能测试等,具体流程如下:

(1)外观检查:检查接缝外观是否平整、无瑕疵,颜色是否均匀。

(2)尺寸测量:根据标准尺寸,对接缝部位进行精确测量。

(3)拉伸性能测试:通过拉伸试验机对接缝进行拉伸测试,观察接缝的拉伸强度和延伸率。

(4)撕裂性能测试:通过撕裂试验机对接缝进行撕裂测试,观察接缝的撕裂强度和耐撕裂性能。

案例分析

以某品牌纺织品为例,其接缝性能检测的具体步骤如下:

(1)外观检查:检查接缝部位外观平整,颜色均匀。

(2)尺寸测量:根据标准尺寸,对接缝部位进行精确测量。

(3)拉伸性能测试:使用拉伸试验机对接缝进行拉伸测试,发现接缝的拉伸强度较高,延伸率适中,符合标准要求。

(4)撕裂性能测试:通过撕裂试验机对接缝进行撕裂测试,发现接缝具有较好的耐撕裂性能,能够承受一定程度的撕裂力。

纺织品接缝性能检测案例说明

某品牌棉质衬衫的接缝性能检测

该品牌棉质衬衫采用高质量的纤维材料制成,经过严格的工艺流程和检测标准,确保接缝性能达到国家标准,在外观检查中,接缝部位平整、无瑕疵;尺寸测量结果显示,接缝尺寸准确无误;拉伸性能测试中,接缝的拉伸强度较高,延伸率适中,符合标准要求;撕裂性能测试中,接缝具有较好的耐撕裂性能,能够承受一定程度的撕裂力,该品牌棉质衬衫的接缝性能得到了消费者的认可和好评。

某品牌牛仔布的接缝性能检测

该品牌牛仔布采用高品质的牛仔布纤维材料制成,经过特殊的工艺处理和检测标准,确保接缝处具有优良的耐磨性和抗撕裂性能,在外观检查中,接缝处颜色均匀、纹理清晰;尺寸测量结果显示,接缝尺寸符合标准要求;拉伸性能测试中,牛仔布的拉伸强度较高,能够承受一定程度的拉伸变形;撕裂性能测试中,牛仔布具有较好的耐撕裂性能和耐磨性,能够满足不同场合的使用需求,该品牌牛仔布的接缝性能得到了消费者的信赖和好评。

纺织品接缝性能检测对于保证产品质量、提高产品竞争力具有重要意义,在纺织品生产过程中,应严格按照检测标准进行接缝性能检测,确保产品的质量和耐用性,消费者在购买纺织品时也应关注产品的接缝性能检测结果,选择符合国家标准的产品,随着科技的不断进步和纺织品生产工艺的不断改进,未来纺织品接缝性能检测将更加精准、高效,为纺织品生产企业和消费者提供更加优质的服务。

Articles related to the knowledge points of this article:

Expanding the Canvas of Fashion:The Multi-Stamp Technique in Textiles

Broadening Horizons:Exploring the Global Reach of Wus Textiles

The Causes of Pre-Shrinkage in Textiles

The Evolution and Innovative Strategies of Guangzhou Hengye Textiles