Textile Finishing Basics:An Introductory Guide to Post-Treatment Processes

This article provides an overview of textile finishing processes, including the basic steps involved in post-treatment procedures. It covers topics such as dyeing, printing, coating, and finishing techniques, including padding, stitching, and ironing. The article also discusses the importance of proper pretreatment and post-treatment procedures to achieve optimal results in textile products. Additionally, it highlights the benefits of using eco-friendly and sustainable materials in textile production. Overall, this article serves as a comprehensive guide for those interested in learning more about the various finishing processes used in the textile industry.

Introduction: Textile finishing is the final step in the manufacturing process that involves various treatments to enhance the quality, durability, and appearance of textile products. These treatments can include dyeing, printing, coating, finishing, and finishing. In this guide, we will delve into some of the most common post-treatment processes used in textile industries.

I. Dyeing: Dyeing is the process of applying color to fabric by treating it with a dye bath. The choice of dye depends on the desired shade and fastness properties of the finished product. There are two main types of dyeing: direct dyeing and reactive dyeing.

Direct dyeing: In this method, the dye is added directly to the bath containing the fabric. This process is quick and easy, but the colors may not be as vibrant or long-lasting as those obtained through reactive dyeing.

Reactive dyeing: In this process, the fabric is first treated with a chemical that reacts with the dye molecules. Once the reaction is complete, the fabric is washed and dried. This method provides more vibrant colors and longer-lasting finishes compared to direct dyeing.

II. Printing: Printing involves the application of designs onto fabric using different techniques such as screen printing, embroidery, and digital printing. Each technique has its unique advantages and disadvantages, but all involve the use of inks or pastes to transfer the design onto the fabric.

Screen printing: This method uses a mesh screen to apply ink onto the fabric. The screen is covered with a layer of paper and pressed onto the fabric. The ink is then dried and cured to form a permanent image. This technique is commonly used for t-shirts, mugs, and other printed products.

Embroidery: Embroidery involves stitching small designs onto fabric using threads or beads. This technique is often used for garments like jackets, shirts, and dresses. It adds a unique texture and pattern to the fabric.

Digital printing: Digital printing involves using a computer to create and print patterns onto fabric. This method is fast and versatile, allowing for complex designs and customization. However, it requires specialized equipment and software.

III. Coating: Coating is the application of a thin layer of material to protect the surface of a textile from wear and tear. There are several types of coatings used in textile finishing, including waterproofing, flame retardant, antistatic, and antibacterial coatings.

Waterproofing: Waterproofing involves treating fabric with a polymeric material that creates a barrier against water. This prevents moisture from seeping through the fabric and causing damage. Common applications include raincoats, swimwear, and outdoor clothing.

Flame retardant: Flame retardant coatings reduce the risk of fire by reducing the amount of heat generated during combustion. They are commonly used in apparel, furniture, and upholstery.

Antistatic: Antistatic coatings reduce static electricity buildup on fabric surfaces, preventing it from attracting dust and dirt. This is important for garments like sportswear and linens.

Antibacterial: Antibacterial coatings kill bacteria that cause stains and odors on fabric surfaces. They are commonly used in hospital gowns, surgical gloves, and other medical equipment.

IV. Finishing: Finishing is the final step in the textile processing chain that brings out the best features of the fabric. There are several methods of finishing, including waxing, polishing, and coating.

Waxing: Waxing involves applying a wax to the fabric surface to create a smooth finish. This method is commonly used for carpets, upholstery, and other home furnishings.

Polishing: Polishing involves rubbing a soft cloth over the fabric surface to remove any rough edges or imperfections. This method is often used for clothing and other textiles that require a polished look.

Coating: Coating involves applying a thin layer of material to the fabric surface to protect it from wear and tear. There are several types of coatings used in textile finishing, including waterproofing, flame retardant, antistatic, and antibacterial coatings.

V. Case Study: Let's take a look at how a case study involving a high-end fashion brand showcases the importance of post-treatment processes in creating exceptional textile products.

The brand's designers wanted to create a new collection of luxury resort wear that would exude elegance and sophistication. To achieve this, they approached their textile supplier with a request for high-quality fabrics with vibrant colors and long-lasting finishes. The supplier provided them with a selection of fabrics that were dyed using reactive dyeing techniques, resulting in vivid and lasting shades.

Next, they applied a waterproofing treatment to the fabrics, ensuring that they could withstand the harsh conditions of a high-end resort environment. The waterproofing process also added an extra layer of protection against watermarks and fading, which is essential for maintaining the brand's reputation for quality and durability.

After the fabrics were treated, they were sent to the manufacturer for a series of finishing processes, including waxing and polishing. The waxing process created a smooth and glossy finish that enhanced the visual appeal of the fabrics. The polishing process removed any remaining imperfections and left the fabrics looking flawless.

Finally, the completed fabrics were packaged and shipped to the fashion brand for use in their new resort collection. The results were nothing short of spectacular - the fabrics looked stunning in person, with vibrant colors and a luxurious sheen. The brand's customers were thrilled with the end result, recognizing the importance of high-quality post-treatment processes in achieving exceptional textile products.

Conclusion: Post-treatment processes play a crucial role in enhancing the quality, durability, and appearance of textile products. By understanding the different techniques used in textile finishing, manufacturers can create products that meet the needs of their customers while maintaining their brand's reputation for excellence.

纺织品后整理概述

随着纺织行业的快速发展,纺织品后整理技术已成为提升产品质量、满足消费者需求的重要手段,本教材旨在为从事纺织品后整理工作的教育工作者和从业者提供全面、系统的知识体系。 结构与章节安排

本教材分为多个章节,详细介绍了纺织品后整理的原理、技术、工艺流程以及实际应用案例,以下是章节安排和内容概述:

纺织品后整理的基本原理

介绍纺织品后整理的定义、目的和重要性。 讨论后整理技术的基本分类,如柔软整理、防皱整理、色织整理等。

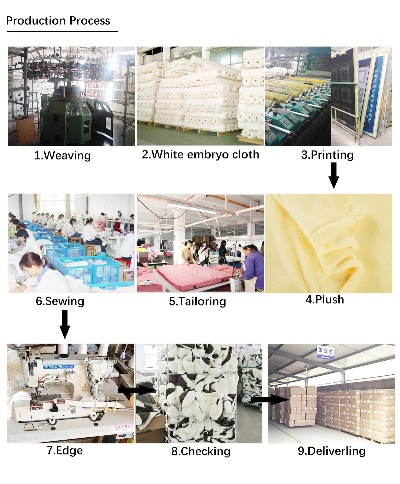

纺织品后整理工艺流程

详细描述纺织品从原料到成品的全过程,包括预处理、染色、印花、整理等环节。 强调各环节的关键工艺参数和操作要点。

纺织品后整理技术应用案例

通过实际案例分析,展示不同类型纺织品后整理技术的应用效果。 案例包括柔软整理在丝绸面料中的应用、防皱整理在棉布面料中的实践等。

教材特色与亮点

本教材具有以下特色与亮点:

- 理论与实践相结合:教材内容紧密结合实际,通过案例分析加深理解。

- 图文并茂:教材中包含大量的图表和图片,直观展示纺织品后整理的工艺流程和效果。

- 实用性强:教材内容全面,涵盖纺织品后整理的各个方面,适合不同层次的从业者学习。

教材案例说明

以下是关于纺织品后整理技术应用案例的英文案例说明:

柔软整理在丝绸面料中的应用

在丝绸面料生产过程中,柔软整理技术被广泛应用于提高丝绸面料的柔软度和舒适度,通过添加柔软剂、柔软剂与助剂复合等工艺,可以显著提高丝绸面料的触感柔软度和弹性,在实际应用中,柔软整理技术可以应用于丝绸服装、披肩等高端纺织品。

防皱整理在棉布面料中的实践

在棉布面料生产过程中,防皱整理技术被广泛应用于提高棉布面料的抗皱性和耐久性,通过添加防皱剂、热处理等工艺,可以显著提高棉布面料的抗皱性和耐久性,在实际应用中,防皱整理技术可以应用于棉布衬衫、运动服等日常纺织品,随着科技的不断进步,新型防皱整理技术如纳米技术等也在不断发展,为纺织品后整理领域带来了新的发展机遇。 补充说明(表格)

以下是关于纺织品后整理教材内容的补充说明表格: | 主要知识点 | 相关图表或图片 | 相关案例分析 | 补充说明 | | --- | --- | --- | --- | --- | | 纺织品后整理的基本原理 | 后整理的定义、目的和重要性 | 后整理工艺流程图 | 柔软整理在丝绸面料中的应用案例 | 后整理技术在丝绸面料中的应用广泛,通过添加柔软剂等工艺提高触感柔软度和弹性 | | | 后整理的技术分类 | | | 后整理技术可根据不同需求进行分类,如柔软、防皱等 | | 纺织品后整理工艺流程 | 从原料到成品的全过程 | 工艺流程图 | 色织印花工艺流程图 | 从原料准备到成品生产涉及预处理、染色、印花等多个环节 | | 纺织品后整理技术应用案例 | 应用实例分析 | 相关图表或图片 | 柔软整理在棉布面料中的实践案例 | 通过实际案例分析,展示不同类型纺织品后整理技术的应用效果,如柔软整理在棉布面料中的应用效果等 | | 理论与实践相结合 | 通过案例加深理解 | 通过图表和图片展示工艺流程和效果 | 通过实际案例加深对理论知识的理解和应用 | 本教材注重理论与实践相结合,通过案例分析加深理解,有助于提高从业者的实际操作能力 | | 图文并茂 | 图文结合介绍知识点 | 相关图文介绍 | 通过图文介绍加深对知识的理解和记忆 | 本教材图文并茂,有助于提高学习效果和记忆能力 | | 实用性强 | 涵盖各个方面 | 涵盖各个方面 | 涵盖纺织品后整理的各个方面,适合不同层次的从业者学习 | 本教材实用性强,适合不同层次的从业者学习,有助于提高从业者的实际操作能力和技术水平 |

本教材以纺织品后整理为主题,全面介绍了纺织品后整理的基本原理、技术、工艺流程以及实际应用案例,通过图文并茂的方式,帮助从业者更好地理解和掌握纺织品后整理的相关知识,本教材还注重理论与实践相结合,有助于提高从业者的实际操作能力和技术水平。

Articles related to the knowledge points of this article:

The Fabrication of a Future:A Comprehensive Guide to Textile Planning

An Extensive Guide to Printed Textiles:Types,Uses,and Case Studies

The Art of Textile Dyeing A Comprehensive Guide

The Current Rates and Policies for Chinese Imported Textiles