The Evolutionary Journey of Textile Finishing

: The Evolutionary Journey of Textile Finishing,Textile finishing is a crucial step in the manufacturing process that not only enhances the appearance and durability of textiles but also contributes to their functional properties. This evolutionary journey of textile finishing has been marked by significant advancements in technology, materials, and processes that have revolutionized the way we perceive and use textiles.,In the early days of textile manufacturing, finishing involved simple techniques such as dying with natural dyes or applying waxes to protect the fabric from wear and tear. However, as industrialization and mass production became more prevalent, there was a need for faster and more efficient methods of finishing. This led to the development of chemical dyeing and printing, which allowed for larger-scale production and greater variety in color and pattern.,As technology continued to advance, finishing techniques became more sophisticated, incorporating heat treatment, embossing, and other processes that enhanced the texture and aesthetic appeal of the finished textiles. Additionally, the introduction of eco-friendly finishes and sustainable materials has become increasingly important in today's market, reflecting a growing awareness of environmental responsibility.,Today, textile finishing is a dynamic field that continues to evolve, driven by innovations in materials science, bioengineering, and digital technologies. From the latest in nanotechnology-based finishes to the integration of artificial intelligence and machine learning into the finishing process, the future of textile finishing looks promising, with endless possibilities for enhancing our ability to create and customize textile products.

In the realm of textiles, the journey of finishing is akin to a grand symphony that has been composed over centuries. From ancient techniques to modern innovations, this process has transformed the fabric we wear and touch into something more than just raw materials. Today, let's delve into the history of textile finishing and explore how it has shaped our world.

Textile Finishing: A Historical Perspective

The origins of textile finishing can be traced back to ancient civilizations, where skilled artisans used simple methods to enhance the durability and appearance of their creations. For instance, in China, silk was first dyed using natural pigments like indigo or turmeric, while in India, cotton was treated with a variety of substances such as oil or resin to improve its texture and color. These early techniques were based on trial and error, but they laid the foundation for future developments.

Classical Techniques

As textile production grew, so did the need for finishing techniques. In the Middle Ages, European weavers began to use chemicals like tannin and resin to create a protective layer on their fabrics. This led to the development of "finishing" as a distinct process, separate from dyeing and weaving. By the 17th century, finishing techniques had evolved significantly, with the introduction of waxes, oils, and resins to create glossy, waterproof finishes.

Industrial Revolution

The Industrial Revolution brought about significant changes in the way textiles were produced and finished. With the advent of machines, textile workers had to adapt their skills to meet new demands. This period saw the rise of chemical finishes, which allowed for faster and more consistent results. Chemical finishes became the standard for many industries, including clothing and upholstery.

Modern Techniques

Today, textile finishing is a highly specialized field that involves a wide range of processes and technologies. Some of the most common finishing techniques include:

-

Dyeing: This involves applying dyestuffs directly onto the fabric to create vibrant colors. Dyeing methods have evolved greatly over time, from traditional vats to modern spray and pad techniques.

-

Finishing with Oils: This technique involves treating fabric with a mixture of solvents and oils to create a protective coating. This coating helps to prevent fading, staining, and other damage caused by exposure to sunlight, water, and other elements.

-

Resin Treatment: Resin treatments involve applying a liquid resin to the fabric, which hardens and creates a protective layer on the surface. This treatment can also enhance the fabric's texture and appearance.

-

Wax Stamping: This technique involves applying a layer of wax onto the fabric and then pressing it with a stamp. The wax forms a protective layer on the surface, which helps to prevent fading and damage.

-

Heat Stamping: Heat stamping involves heating the fabric with a hot iron before applying a wax or resin. This method creates a strong, durable finish that can withstand heavy use and weather conditions.

-

UV Stamping: UV stamping involves treating the fabric with a UV light source before applying a wax or resin. This method creates a long-lasting, fade-resistant finish that can withstand even harsh outdoor conditions.

Case Study: The Rise of Eco-Friendly Textiles

In recent years, there has been a growing trend towards eco-friendly textiles, driven by concerns about environmental impact and consumer preferences. This has led to the development of new finishing techniques that are both sustainable and effective. For example, biodegradable finishes have become popular, as they reduce the risk of harmful chemicals entering landfills. Additionally, some companies are experimenting with using recycled materials in their finishing processes, further reducing waste and promoting sustainability.

Conclusion

The evolution of textile finishing has been a fascinating journey, marked by advancements in technology and changing consumer needs. From ancient techniques to modern innovations, textile finishing has played a crucial role in shaping our lives and the world around us. As we continue to push boundaries in this field, we can expect even more exciting developments in the future.

纺织品整理作为提升纺织品品质和舒适性的重要手段,经历了漫长的发展历程,从最初的简单整理到如今的精细工艺,其背后蕴含着科技、工艺和人类智慧的结晶,本文将通过图表和案例,详细阐述纺织品整理的发展历程。

早期纺织品整理技术

早期纺织品整理主要依赖于手工操作和简单的机械设备,主要采用简单的整理方法,如染色、印花等,随着纺织技术的进步,人们开始尝试使用化学整理剂来改善纺织品的性能,使用染料进行染色,通过调整染料的浓度和温度来达到理想的颜色效果,还有使用粘合剂进行织物加固的处理方式。

现代纺织品整理技术的发展历程

-

科技驱动:随着科技的进步,纺织品整理技术也得到了飞速发展,现代纺织品整理技术更加注重环保、高效和个性化,纳米技术被广泛应用于纺织品的表面处理,提高了织物的耐磨性、防污性等性能,智能纺织品的发展也为纺织品整理带来了新的可能性。

-

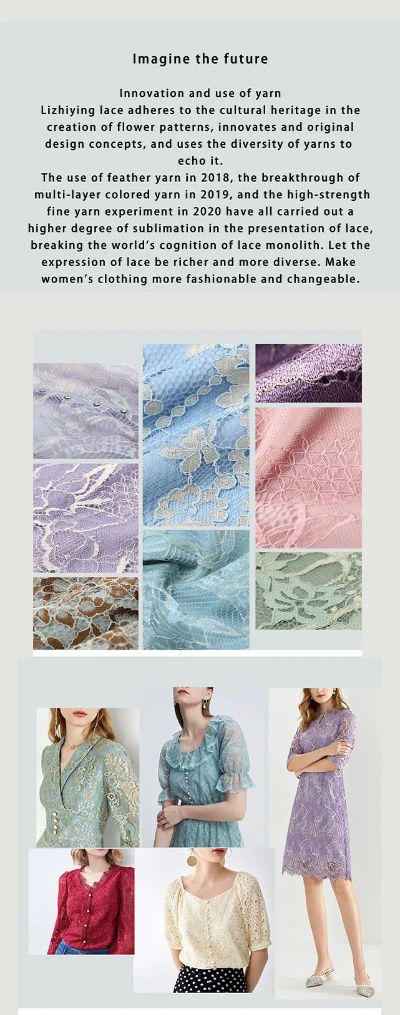

工艺创新:在工艺方面,现代纺织品整理技术更加注重精细化、专业化和个性化,通过使用先进的设备和技术,如气流纺、针织机等,实现了对纺织品的精准处理,还出现了各种新型的整理工艺,如色织、提花等,为纺织品带来了更多的设计可能性。

-

案例分析:以某知名品牌为例,其纺织品整理技术的发展历程可以很好地说明现代纺织品整理技术的发展趋势,该品牌采用了先进的纳米技术对纺织品进行表面处理,提高了织物的耐磨性、防污性等性能,还采用了智能化的整理工艺,实现了对纺织品的个性化定制,该品牌还不断探索新的整理工艺和技术,以满足市场的不断变化和消费者对高品质纺织品的追求。

纺织品整理的发展趋势

-

环保化:随着环保意识的不断提高,纺织品整理也将更加注重环保,纺织品整理将更加注重绿色、低碳、循环利用等理念,采用环保的整理工艺和技术。

-

个性化:随着消费者对个性化需求的不断提高,纺织品整理也将更加注重个性化,纺织品将更加注重设计创新和个性化定制,满足消费者的不同需求。

-

高科技化:未来纺织品整理将更加注重科技驱动,纳米技术、智能技术等高科技将更多地应用于纺织品整理中,提高纺织品的性能和品质。

纺织品整理作为提升纺织品品质和舒适性的重要手段,经历了漫长的发展历程,从早期的简单手工操作到现代的科技驱动和工艺创新,其发展历程充满了科技、工艺和人类智慧的结晶,纺织品整理将继续发展,更加注重环保、个性化和高科技化等趋势,我们也需要不断探索和创新,以满足消费者对高品质纺织品的追求。

Articles related to the knowledge points of this article:

The Future of Fashion with Rayc程纺织品 Your Gateway to Luxurious Textiles

Revolutionizing Textiles:The Future of Material Innovation

The Role of Medical Wearables in Enhancing Healthcare Quality