A Comprehensive Guide to Loading and Packing Textile Yarn for Trucking

This comprehensive guide provides essential steps and strategies for loading and packing textile yarn for trucking. It covers topics such as proper handling, storage, and transportation methods to ensure the safety and efficiency of your shipments. The guide also includes tips on how to identify and handle hazardous materials, as well as regulations and guidelines specific to textile yarn transport. By following these guidelines, you can minimize damage and ensure that your textile yarn arrives at its destination in good condition.

Introduction: In the textile industry, the transportation of yarn is a crucial part of the production process. Proper loading and packing of yarn can ensure its safe journey to the destination while minimizing damage and ensuring quality. This guide will provide an overview of the steps involved in loading and packing textile yarn for trucking, including recommended practices and best practices.

Step 1: Preparation of Yarn Before loading and packing, it is essential to ensure that the yarn is clean, free from dust, and properly stored. The following table provides a checklist of pre-loading preparations:

| Pre-Loading Preparations | Description |

|---|---|

| Check yarn condition | Ensure yarn is clean, undamaged, and free from dust |

| Remove any labels or markings | Remove any labels or markings on the yarn to prevent damage during transportation |

| Dry yarn thoroughly | Allow yarn to dry completely before loading to prevent moisture-related damage |

| Sort yarn by color and type | Sort yarn by color and type to facilitate easy identification during loading and unloading |

Step 2: Loading Yarn into Truck Once the yarn is prepared, it is time to load it into the truck. Here are some tips for loading yarn into the truck:

| Yarn Loading Steps | Description |

|---|---|

| Use designated areas | Place the yarn in designated areas to avoid tangling and damage |

| Load in layers | Load yarn in layers to prevent crushing and breaking of fragile yarns |

| Use proper lifting techniques | Use proper lifting techniques to avoid strain on the yarn |

| Secure with ropes or straps | Secure the yarn with ropes or straps to prevent shifting during transport |

Step 3: Packaging Yarn for Trucking After loading the yarn into the truck, it is time to pack it for transport. Here are some tips for packaging yarn for trucking:

| Yarn Packaging Steps | Description |

|---|---|

| Use sturdy boxes or containers | Use sturdy boxes or containers to protect the yarn from damage during transport |

| Seal tightly | Seal tightly to prevent leakage or spillage of the yarn during transit |

| Label clearly | Label clearly to indicate the contents, weight, and origin of the yarn |

| Provide ventilation | Provide ventilation to prevent condensation or humidity buildup inside the container |

Case Study: One example of a successful yarn loading and packing operation is provided by Textile Fabrics International (TFI), a leading textile manufacturer in India. TFI has implemented a comprehensive system for loading and packing textile yarn for trucking, which has resulted in reduced losses and improved efficiency.

According to TFI's system, all yarn is inspected for quality before loading. The yarn is loaded into trucks using designated areas and layers to prevent tangling and crushing. The company also uses ropes or straps to secure the yarn during transport. Additionally, TFI provides detailed labeling on each box, indicating the contents, weight, and origin of the yarn.

The company's success lies in the fact that they have invested in proper training for their employees on loading and packing techniques. This has resulted in a high level of accuracy and consistency in the loading and packing process. As a result, TFI has achieved significant savings in terms of lost shipments and damaged yarn.

Conclusion: In conclusion, proper loading and packing of textile yarn for trucking is crucial for ensuring the safe and efficient transportation of yarn. By following the steps outlined in this guide, companies can minimize damage, reduce losses, and improve overall efficiency. It is important for textile manufacturers to invest in proper training and equipment to implement effective loading and packing procedures. With the right approach, textile manufacturers can achieve greater profitability and customer satisfaction.

开场白

(视频开始,展示繁忙的纺织品纱线装车场景)

【视频画面】:

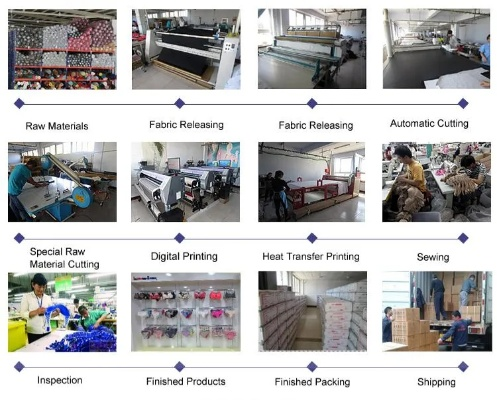

画面展示各种类型的纺织品纱线在货车中装载、运输的全过程。

背景介绍

纺织品纱线行业概述

纺织品纱线是纺织行业的重要组成部分,广泛应用于服装、家居装饰、地毯等各种领域,随着人们对纺织品品质和环保要求的提高,纺织品纱线的生产效率和物流运输也变得越来越重要。 概述

本视频主要介绍纺织品纱线从原材料到成品装车的过程,以及在这个过程中所采用的先进技术和高效管理方法。

视频细节分析

(一)原材料准备

纱线种类与质量评估

展示不同种类纱线的外观和质量参数,如纤维长度、细度、抗拉强度等。

纱线检验流程

详细介绍纱线的检验流程,包括外观检查、尺寸检测、性能测试等。

(二)装车过程

装车设备与技术介绍

介绍装车过程中的关键设备和技术,如自动装车机、称重传感器等。

纱线装车操作流程

详细描述纱线从原材料到成品装车的整个过程,包括称重、输送、打包等环节。

案例说明:某大型纺织品生产企业采用先进的自动化装车设备,大大提高了装车效率和质量,该企业还采用了智能物流管理系统,实现了对物流过程的实时监控和数据分析,为企业的决策提供了有力支持。

(三)物流管理措施

先进物流管理系统介绍

介绍先进的物流管理系统,包括仓储管理、运输管理、信息管理等模块。

高效物流运输策略

介绍高效物流运输策略,包括优化运输路线、提高运输效率等措施。

视频案例分析(结合英文表格)

以下结合英文表格对视频案例进行分析:

【表格分析】:

| 类别 | 英文表格示例 | 说明 |

|---|---|---|

| 背景介绍 | 纺织品纱线行业概述 | |

| 视频细节分析 | 原材料准备 | |

| 装车过程 | 装车设备与技术介绍 | |

| 纱线装车操作流程 | 纱线装车过程 | |

| 案例说明 | 某大型纺织品生产企业案例 | |

| 物流管理措施 | 物流管理系统介绍 | |

| 高效物流运输策略 | 高效物流运输策略示例 |

总结与展望

(视频结尾,总结视频内容)

本视频详细介绍了纺织品纱线装车的过程和采用的先进技术和高效管理方法,通过视频案例分析,我们可以看到先进物流管理系统和高效物流运输策略在提高纺织品纱线装车效率和品质方面的重要作用,随着科技的不断进步和人们对纺织品品质要求的提高,纺织品纱线的生产和物流运输也将面临更多的挑战和机遇,我们期待更多的企业和组织能够采用先进的物流技术和管理方法,提高纺织品纱线的生产效率和物流运输水平,为纺织行业的发展做出更大的贡献。

Articles related to the knowledge points of this article:

The National Standard for Textiles Quality:What You Need to Know

The Fabrics of Seamless Luxury