The Art of Textile Inspection:An Insight into the Science and Practice

: The Art of Textile Inspection: An Insight into the Science and Practice,The art of textile inspection involves a delicate balance between scientific precision and practical experience. It is a multifaceted process that requires both technical expertise and an understanding of human perception, ensuring that every piece of fabric meets quality standards.,At the heart of textile inspection lies the science of materials testing. Technicians use specialized equipment to measure various properties such as colorfastness, washability, and durability. These tests provide valuable insights into how well a fabric will perform in real-world conditions.,However, textile inspection is not just about data collection. It also involves interpreting these results in the context of the finished product. This requires a deep understanding of how different factors, such as thread count or weave pattern, can affect the overall appearance and performance of a garment.,In addition to technical expertise, textile inspectors must also have a keen eye for detail. They must be able to detect even the slightest variations in color or texture, which could compromise the overall aesthetic appeal or functionality of the fabric.,Overall, textile inspection is a complex process that requires a combination of scientific knowledge and practical experience. By mastering this art, inspectors ensure that every piece of fabric they examine meets the highest standards of quality and performance.

Introduction: Textiles, the fabric of our daily lives, are an integral part of human civilization. From luxurious designer wear to functional workwear, textiles play a crucial role in creating comfort, style, and functionality. However, with their wide range of applications, textile products can also pose significant challenges for quality assurance. This is where textile inspection comes into play. In this essay, we will explore the principles and techniques involved in textile inspection, as well as some practical examples that illustrate the importance of stringent testing methods.

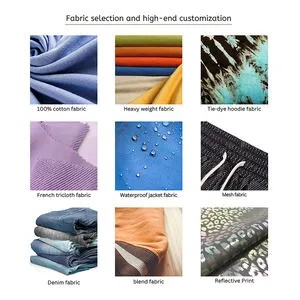

Principles of Textile Inspection: Textile inspection involves the evaluation of various aspects of textile materials, including color, texture, density, strength, and durability. These parameters are critical for ensuring that textile products meet the standards set by regulatory bodies and consumer expectations.

Color Testing: Color plays a significant role in determining the aesthetic appeal of textiles. Color testing involves evaluating the consistency, uniformity, and accuracy of the colors on the fabric. This can be done using spectrophotometers, which measure the intensity and wavelength of light reflected from the fabric. For example, if a fabric has a consistent hue and saturation across different samples, it can be considered to have good color consistency.

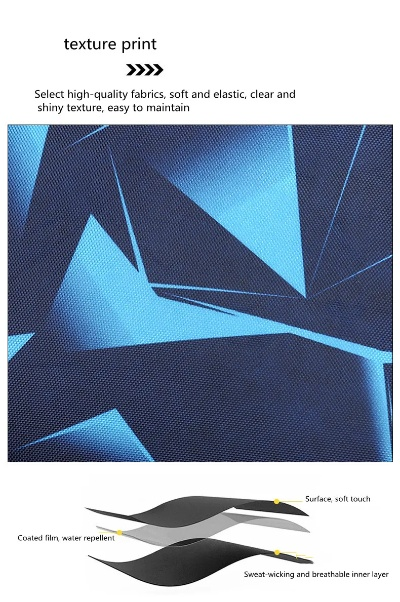

Texture Testing: Texture refers to the feel and appearance of a material. Texture testing involves evaluating the softness, smoothness, and graininess of the fabric. This can be done using a texture analyzer that measures the force required to deform the fabric. For instance, a fabric with a high level of luster or gloss may indicate a higher degree of finish than a duller fabric.

Density Testing: Density is a measure of the number of fibers per square inch of a fabric. High-density fabrics are typically stronger and more durable, while low-density fabrics may be lighter and more breathable. Density testing involves weighing samples and calculating their density based on weight per unit area. For example, a sample with a density of 300 grams/m² may be considered to have medium-high density.

Strength Testing: Strength testing evaluates the resistance of textiles to tearing or breaking. This can be done using a tensile tester that applies tension to the fabric until it breaks. The maximum force required to break the fabric is measured and compared to industry standards. For example, a fabric with a breaking strength of at least 45 N/tex (a standard measure of yarn strength) may be considered to have good strength.

Durability Testing: Durability refers to the ability of textiles to resist wear and tear over time. Durability testing involves subjecting fabric samples to various mechanical stresses such as compression, stretching, and abrasion. The results are used to determine the fabric's resistance to these conditions and its lifespan. For example, a fabric with a high level of resistance to wear and tear may be considered to have good durability.

Practical Example: One practical example of textile inspection is the certification process for clothing materials. Clothing companies must comply with various safety and environmental standards, such as the Oeko-Tex Standard 100 and the Global Organic Textile Standard (GOTS). These standards require companies to conduct regular inspections of their clothing products to ensure they meet the requirements. For example, a company may use a combination of color and texture testing to verify that their denim jeans meet the Oeko-Tex standards for color fastness and softness.

Conclusion: Textile inspection is an essential aspect of the textile industry, ensuring that products meet consumer expectations and regulatory requirements. By understanding the principles of textile inspection and applying them in practical cases, we can better understand the importance of rigorous testing methods in the production and distribution of textile products.

在纺织品检验学领域,我们通过一系列严谨的检验流程确保产品的质量与安全,本篇答案将围绕纺织品检验学的主要知识点展开,结合实际案例,为您提供详尽的英文口语化内容。

纺织品检验学基础知识

纺织品检验的定义与目的

纺织品检验是对纺织品的质量、规格、性能等进行全面检测的过程,以确保其符合相关标准和市场需求,其主要目的是确保纺织品符合安全、环保、健康等要求,为消费者提供优质的产品。

纺织品检验的流程与方法

纺织品检验通常包括样品采集、样品处理、性能测试、质量评估等环节,具体流程如下:样品采集→样品处理→性能测试→结果分析→出具报告,我们还需要根据不同的检验项目采用不同的方法和技术手段。

案例分析

纺织品质量检测

假设某公司生产的一款新型面料在市场上受到广泛关注,为了确保其产品质量,我们进行了以下纺织品质量检测:

(1)样品采集:从市场上随机抽取样品进行检测。 (2)样品处理:对样品进行清洗、干燥等处理,确保样品状态适合进行性能测试。 (3)性能测试:采用相关仪器对面料进行拉伸、耐磨、抗皱等性能测试,根据测试结果,该面料符合相关标准和市场需求。

环保纤维检测

近年来,环保纤维逐渐成为纺织品市场的新趋势,为了检测环保纤维的质量,我们进行了以下案例分析:

(1)样品采集:从市场上收集环保纤维样品。 (2)样品处理:对样品进行必要的预处理,如溶解纤维成分等。 (3)环保纤维检测技术:采用光谱分析、色谱分析等方法检测纤维中的化学成分和含量,根据检测结果,该环保纤维符合环保标准。

纺织品检验学知识点详解

纺织品纤维组成与性质分析

(1)纤维组成:了解纤维的主要成分和含量,如天然纤维和合成纤维等。 (2)纤维性质:分析纤维的吸湿性、透气性、柔软性等特性,为后续性能测试提供依据。

纺织品质量检测方法与技术

(1)外观检测:通过观察纺织品外观,判断其质量是否符合标准。 (2)力学性能测试:通过拉伸、耐磨、抗皱等力学性能测试,评估纺织品的强度和耐用性。 (3)化学成分分析:采用光谱分析、色谱分析等方法检测纺织品的化学成分和含量,确保其符合相关标准和市场需求。 (4)环保标准检测:采用光谱分析等方法检测纤维中的化学成分和含量是否符合环保标准。

案例分析实例

(1)案例一中的新型面料质量检测案例:通过外观检测、性能测试等方法,发现该面料符合相关标准和市场需求,为消费者提供了优质的产品,我们还采用了先进的检测技术手段,提高了检测效率和准确性。

(2)案例二中的环保纤维检测案例:通过光谱分析等方法,发现该环保纤维符合环保标准,为纺织品的环保使用提供了保障,我们还采用了多种检测方法和技术手段,全面评估了纺织品的各项性能指标。

总结与展望

纺织品检验学是确保纺织品质量与安全的重要学科之一,通过掌握纺织品检验学的基础知识和方法,我们可以更好地进行纺织品质量检测和评估,我们还需要不断探索新的技术和方法,提高纺织品检验的准确性和效率性,纺织品检验学将继续发展壮大,为纺织品的生产和销售提供更加可靠和质量保障的产品。

Articles related to the knowledge points of this article:

Recycling Textiles:A Sustainable Approach to Material Renewal