Essential Testing Protocols for Textile Products

: Essential Testing Protocols for Textile Products,In the realm of textile products, testing protocols are crucial to ensure quality and compliance with regulatory standards. This paper outlines essential testing procedures that must be followed to evaluate the performance and durability of textile materials. The first step involves conducting a physical examination, which includes measuring dimensions, weight, and color consistency. Additionally, mechanical properties such as strength and flexibility must be assessed through tensile tests and bend tests, respectively. Chemical stability is evaluated through dyeability and resistance to solvents. Finally, environmental testing is conducted to assess the product's impact on the environment, including its ability to absorb moisture, wick away sweat, and resist pilling and fading. By following these protocols, textile manufacturers can ensure that their products meet industry standards and consumer expectations.

Introduction: Textile products are an integral part of our daily lives, from clothing to bedding, and from sportswear to industrial fabrics. To ensure the quality and safety of these products, it's essential to perform a range of testing protocols. In this guide, we will discuss the most critical tests that are conducted on textile products.

-

Material Testing:

- Denier Testing: This is used to measure the strength of yarns and fabrics. It involves measuring the weight of a thread under tension.

- Tenacity Testing: This test measures the resistance of a material to breaking. It's often used in the production of high-performance fabrics.

- Elasticity Testing: This test evaluates how much a material will return to its original shape after being stretched.

- Weave Analysis: This test checks the structure of the fabric by comparing it with a standard pattern.

-

Chemical Testing:

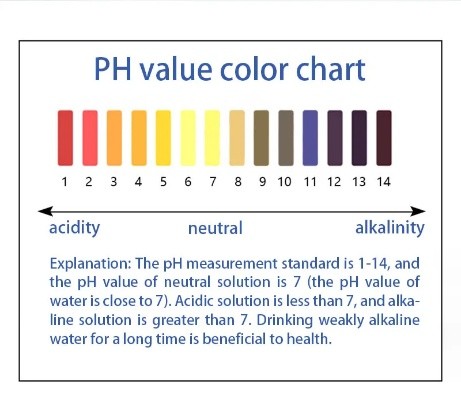

- Moisture Resistance Testing: This test measures how well a fabric can resist moisture penetration. It's important for materials used in outdoor applications like tents and outdoor apparel.

- Flammability Testing: This test determines how easily a fabric catches fire. It's crucial for materials used in construction and manufacturing industries.

- Antimicrobial Testing: This test evaluates the effectiveness of a fabric against harmful bacteria and fungi. It's especially important for healthcare and hygiene applications.

-

Physical Properties Testing:

- Stretch Testing: This test measures how much a fabric can be stretched before it breaks. It's used to assess the durability of fabrics.

- Shrinkage Testing: This test measures how much a fabric shrinks over time. It's important for materials used in garments and home textiles.

- Tenacity Testing: This test measures the resistance of a material to breaking. It's often used in the production of high-performance fabrics.

-

Environmental Testing:

- Climate Controlled Testing: This test simulates the environmental conditions that a product will experience in its intended use. It's crucial for materials used in outdoor applications like tents and outdoor apparel.

- Ecological Testing: This test evaluates the environmental impact of a product. It's important for materials used in construction and manufacturing industries.

- Water Resistance Testing: This test measures how well a fabric can resist water damage. It's important for materials used in marine and industrial applications.

-

Safety Testing:

- Harsh Weather Testing: This test measures how well a fabric can withstand extreme weather conditions. It's important for materials used in outdoor applications like tents and outdoor apparel.

- Fire Retardant Testing: This test determines how well a fabric can resist fire. It's crucial for materials used in construction and manufacturing industries.

- Skin Contact Testing: This test evaluates the potential health risks associated with contact with the fabric. It's important for materials used in healthcare and hygiene applications.

-

Quality Control Testing:

- Size and Fit Testing: This test measures the fit of a garment and ensures that it fits the intended wearer properly.

- Colorfastness Testing: This test measures how well a fabric retains its color under different conditions. It's important for materials used in garments and home textiles.

- Dye Dispersion Testing: This test evaluates the distribution of dye throughout a fabric. It's important for materials used in garments and home textiles.

-

Functional Testing:

- Wear and Tear Testing: This test measures how long a fabric will last under normal wear and tear. It's important for materials used in garments and home textiles.

- Performance Testing: This test measures the functionality of a fabric under specific conditions. It's crucial for materials used in sportswear and other high-performance applications.

Conclusion: Performing the above tests is essential for ensuring the quality and safety of textile products. By following these guidelines, manufacturers can produce products that meet the needs of their customers and adhere to industry standards.

大家好,今天我们来聊聊纺织品的主要检测项目及其重要性,纺织品作为我们日常生活中不可或缺的原材料,其质量直接关系到产品的性能、安全以及消费者的使用体验,下面我们将详细介绍纺织品主要做哪些检测,并结合案例说明来加深理解。

纺织品主要检测项目

纤维成分检测

纤维成分是衡量纺织品质量的基础,通过纤维成分检测,可以了解纤维的种类、含量以及纤维的均匀性等,这对于确保纺织品的性能和安全性至关重要,检测是否含有对人体无害的天然纤维成分,是否符合环保标准等。

强度与耐磨性检测

纺织品在使用过程中需要具备一定的强度和耐磨性,以适应各种环境条件,强度检测可以评估纺织品的抗拉强度、撕裂强度等,而耐磨性检测则可以通过摩擦测试、磨损测试等方式进行,这些检测可以确保纺织品在各种使用场景下都能保持良好的性能。

尺寸稳定性检测

尺寸稳定性是衡量纺织品尺寸变化的重要指标,通过尺寸稳定性检测,可以确保纺织品在加工、运输、存储等过程中的尺寸变化在允许范围内,从而保证产品的尺寸精度和质量稳定性。

化学成分检测

纺织品在使用过程中可能会接触到各种化学物质,因此化学成分检测也是必不可少的,通过化学成分检测,可以了解纺织品的材质、耐腐蚀性、耐热性等特性,以确保纺织品在使用过程中不会对环境或人体造成损害。

环保性能检测

随着环保意识的提高,纺织品在生产过程中对环境的影响也日益受到关注,环保性能检测可以评估纺织品的环保标准是否符合要求,是否符合国家或行业标准,是否通过了ISO 14001环境管理体系认证等。

案例说明

以某知名品牌的一款纺织品为例,其主要检测项目及其案例说明如下:

纤维成分检测

该品牌的一款纺织品采用了高品质的天然纤维作为原材料,经过严格的纤维成分检测,确认其纤维种类、含量以及纤维的均匀性均符合国家标准,该产品具有优良的吸湿性、透气性和保暖性,深受消费者喜爱。

尺寸稳定性检测

该品牌的一款纺织品在生产过程中采用了先进的生产技术,确保了尺寸稳定性,经过尺寸稳定性检测,产品尺寸精度高,保证了产品的尺寸精度和质量稳定性,该产品广泛应用于服装、家居用品等领域,得到了广泛认可。

纺织品的主要检测项目包括纤维成分检测、强度与耐磨性检测、尺寸稳定性检测、化学成分检测和环保性能检测等,通过这些检测,可以确保纺织品的性能和安全性,提高产品的质量稳定性,满足消费者的使用需求,随着环保意识的提高,纺织品在生产过程中对环境的影响也日益受到关注,在纺织品生产过程中,必须严格遵守相关标准和规范,确保产品的环保性能符合要求。

Articles related to the knowledge points of this article:

Hainans Textile Industry Boosts Promotion with Price Incentives

Unlocking the Benefits of EPR Compliance for French Textile Exporters