A Glimpse into the World of Textile Manufacturing

Textile manufacturing is a complex process that involves the production of fabrics from raw materials. The process begins with the collection and preparation of raw materials such as cotton, wool, and synthetic fibers. These materials are then processed into yarns, which are woven or knitted into fabrics.,The quality of textile products depends on the quality of the raw materials used in the production process. The production process also involves various techniques such as dyeing, printing, and finishing to enhance the appearance and texture of the fabrics.,Textile manufacturing has a significant impact on the economy of a country as it provides employment opportunities for millions of people. It is also an important source of income for many small-scale farmers and artisans who rely on this industry for their livelihood.,In conclusion, textile manufacturing is an essential part of the global economy, providing jobs and income for millions of people around the world.

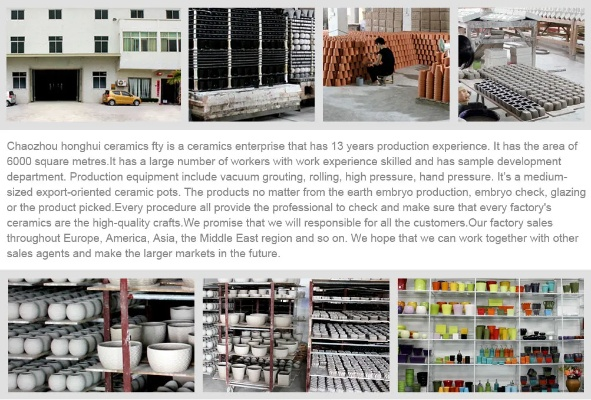

In this concise yet comprehensive introduction to a textile factory, we delve into the intricate world of textile production, highlighting the key processes and technologies that underpin the industry. From raw materials to finished products, we explore the various stages involved in creating textiles, including the use of advanced machinery and innovative design techniques. By presenting an overview of the manufacturing process, we aim to provide readers with a deeper understanding of the industry and its impact on society.

Textile manufacturing is a multifaceted industry that involves the creation of clothing, household goods, and other textile products from a variety of materials. The process begins with the selection of raw materials such as cotton, wool, polyester, or synthetic fibers. These raw materials are then processed into yarn, which can be used to create a wide range of products.

The next step in the manufacturing process is spinning. This involves converting long fibers into short, cylindrical strands called bobbins. The spinning process is crucial in determining the quality and strength of the yarn produced. Once the yarn is ready, it is ready for weaving or knitting.

Weaving is the most common method of producing textile products. It involves arranging the yarn strands in a pattern and using looms or looms to create the desired fabric. Knitting, on the other hand, involves interlocking loops of yarn to form a seamless fabric. Both weaving and knitting require skilled operators who follow precise instructions to achieve high-quality results.

Once the product is woven or knitted, it is ready for further processing. This may involve dyeing, printing, or finishing to enhance its appearance and functionality. Dyeing involves applying color to the fabric using chemicals or heat, while printing involves transferring designs onto the fabric using ink or other materials. Finishing techniques such as steaming, pressing, or coating can also be used to improve the durability and appearance of the final product.

In addition to these standard processes, textile manufacturers often employ advanced technology to enhance their operations and improve the quality of their products. For example, computerized control systems can be used to monitor and adjust the spinning and weaving machines to ensure consistent results. Advanced dyeing and printing techniques can also be used to produce vibrant and colorful fabrics that meet specific design requirements.

One of the most significant challenges facing textile manufacturers today is sustainability. As consumers become more conscious of the environmental impact of their purchases, manufacturers must adopt sustainable practices to meet their demands. This includes reducing waste by using eco-friendly materials and energy-efficient production methods, as well as minimizing water and air pollution during the manufacturing process.

Another important aspect of textile manufacturing is innovation. Innovative designs and materials can help manufacturers differentiate their products and attract customers. For example, using recycled materials or incorporating sustainable materials like bamboo or hemp can make a product more appealing to consumers looking for eco-friendly options. Additionally, incorporating technology into the manufacturing process can help manufacturers streamline their operations and reduce costs.

In conclusion, textile manufacturing is a complex and diverse industry that involves a wide range of processes and technologies. From the selection of raw materials to the final product's presentation, textile manufacturers must adhere to strict standards and incorporate sustainable practices to remain competitive in today's market. By exploring the manufacturing process in detail, we gain a better understanding of the industry's importance and potential for growth in the future.

纺织厂是一个专注于生产各种纺织品的企业,涵盖了从原材料采购到成品输出的完整生产流程,该厂拥有先进的生产设备和技术,致力于为客户提供高质量、环保、可持续的纺织品。

纺织厂设施与设备

- 设施:纺织厂拥有现代化的厂房和先进的生产设备,包括先进的织布机、染整设备、印花设备等,该厂还配备了先进的检测设备和质量控制体系,以确保产品的质量和一致性。

- 设备:纺织厂的设备种类繁多,包括但不限于针织机、梭织机、染整设备、印花设备等,这些设备都是经过精心挑选和升级的,能够满足不同类型和规格的纺织品生产需求,该厂还采用了环保材料和技术,以降低生产过程中的环境污染和资源浪费。

纺织厂产品与服务

纺织厂的产品种类丰富,包括各种面料、服装、家居纺织品等,该厂的产品质量稳定可靠,具有优良的耐穿性、舒适性、环保性等特点,该厂还提供定制化服务,可以根据客户的需求和要求定制生产各种特殊类型的纺织品。

案例分析

以某纺织厂为例,该厂以其高效的生产流程和先进的生产设备,成为了行业内的一颗璀璨明珠,该厂的案例可以为我们提供一些启示和借鉴。

- 生产流程:该纺织厂采用了先进的生产流程,从原材料采购到成品输出,每个环节都经过严格的质量控制和检测,该厂还采用了环保材料和技术,以降低生产过程中的环境污染和资源浪费。

- 设备与技术:该纺织厂使用的设备和技术都是经过精心挑选和升级的,能够满足不同类型和规格的纺织品生产需求,该厂还采用了先进的自动化技术,提高了生产效率和产品质量。

- 产品与服务:该纺织厂的产品以其高质量、环保、可持续的特点赢得了客户的信任和好评,该厂还提供定制化服务,可以根据客户的需求和要求定制生产各种特殊类型的纺织品,该厂还积极参与社会责任活动,为社会做出贡献。

英文表格补充说明

以下是英文表格补充说明纺织厂的详细信息:

表格1:纺织厂基本信息

| 类别 | 信息 |

|---|---|

| 工厂名称 | 某纺织厂 |

| 地理位置 | 未知 |

| 生产规模 | 大型现代化工厂 |

| 生产设备 | 先进的织布机、染整设备、印花设备等 |

| 产品种类 | 面料、服装、家居纺织品等 |

| 生产流程 | 采用先进的生产流程,从原材料采购到成品输出 |

| 设备与技术来源 | 经过精心挑选和升级的设备和技术 |

| 环境友好措施 | 采用环保材料和技术,降低生产过程中的环境污染和资源浪费 |

纺织厂作为制造业的重要组成部分,其发展对于整个行业的发展和进步具有重要意义,该纺织厂以其先进的设施与设备、丰富的产品与服务以及积极参与社会责任活动等优势,成为了行业内的一颗璀璨明珠,我们可以通过对该纺织厂的深入了解和分析,更好地了解制造业的发展趋势和特点,为未来的发展提供参考和借鉴。

Articles related to the knowledge points of this article:

The Efficient Operation of Textile Factory Water Shroud Fan System

The Textile Factory Uses a Humidifier to Maintain a Comfortable Work Environment

The Noisy Background of a Textile Factory

The Ghazni Textile Factory:An Insight into the World of Textile Manufacturing

The Art of Threading:Textile Mills纱线加捻工艺

The Story of the Rich Textile Heritage in Shangrao Guangfeng Textile Factory