The American Textile Industry:A Journey Through the Machines

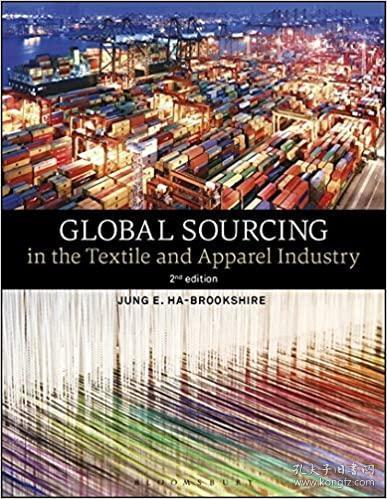

This article delves into the evolution of the American textile industry, tracing its roots to the early 19th century when the Industrial Revolution swept across Europe. The United States, with its vast natural resources and fertile soil, became a hub for textile manufacturing, fueled by innovation and technological advancements.,As the industry expanded, so did the use of machines in the production process. From simple hand-looms to complex factories employing thousands of workers, the textile industry underwent significant changes. The introduction of power tools and automated machinery revolutionized the industry, allowing for increased efficiency and quality control.,The growth of the American textile industry was not without its challenges, however. Environmental concerns emerged as concerns over pollution and waste grew, leading to regulations and initiatives aimed at sustainable practices. Additionally, labor issues arose as concerns over wages and working conditions mounted, prompting calls for greater regulation and worker protection.,Despite these challenges, the American textile industry continued to thrive, becoming an important part of the country's economy and culture. Its legacy can still be seen today in the products we wear and the jobs it created, reflecting a rich history and a vibrant future.

Introduction: The textile industry is one of the pillars of American manufacturing, with its roots stretching back to the early 19th century. From the earliest factories in New England to today's global conglomerates, the American textile industry has undergone significant transformations and innovations over time. One of the most notable aspects of this industry is the use of advanced machinery that has allowed it to remain competitive in a rapidly evolving global market. In this article, we will explore some of the key machines used in the American textile industry and how they have shaped its evolution.

Machinery Used in the American Textile Industry:

-

Looms:

- Pattern loom: This type of loom is used for creating complex patterns on fabrics such as shirting, tablecloths, and curtains. It is a highly skilled operation that requires a great deal of manual dexterity and precision.

- Regular loom: This type of loom is used for producing basic cotton goods such as sheets, towels, and underwear. It is more efficient than the pattern loom but still requires a certain level of skill and attention to detail.

-

Weaving Machines:

- Broadloom: This machine is used for producing woven fabrics such as carpets, upholstery, and rugs. It is a highly automated process that allows for large-scale production.

- Spinning frame: This machine is used for spinning yarn from raw materials such as cotton or wool. It is a crucial step in the textile industry as it determines the quality and strength of the final product.

-

Drafting Machines:

- Drafting machine: This machine is used for shaping and forming fabrics into various shapes and sizes. It is a critical tool in the textile industry as it ensures that each piece of fabric meets the required specifications.

- Stitching machine: This machine is used for sewing together fabrics using thread or other materials. It is a highly specialized operation that requires a great deal of skill and attention to detail.

-

Finishing Machines:

- Staining machine: This machine is used for applying dyes and fixing them onto fabrics. It is a crucial step in the textile industry as it enhances the appearance and durability of the final product.

- Embossing machine: This machine is used for adding texture and depth to fabrics by embossing them with raised ridges or designs. It is a highly specialized operation that requires a great deal of skill and attention to detail.

Case Study: One example of an innovative machine used in the American textile industry is the computerized knitting machine. This machine was developed in the 1960s and has since become an essential tool in the textile industry. By using computer technology, these machines can produce intricate patterns and designs on fabrics with greater accuracy and efficiency than traditional methods.

Another example is the use of robotics in the textile industry. Robots are being used to perform tasks such as cutting, stitching, and finishing fabrics. These machines have the potential to increase productivity and reduce labor costs, while also improving the consistency and quality of the final product.

Conclusion: The American textile industry has been shaped by a variety of advanced machinery over time. From simple looms to complex computerized knitting machines, these machines have allowed the industry to remain competitive in a rapidly evolving global market. As technology continues to advance, we can expect even more innovative machines to be developed and implemented in the future, further enhancing the efficiency and quality of the American textile industry.

背景介绍

近年来,随着科技的飞速发展,纺织行业也在不断进步,美国纺织厂在机器设备方面取得了显著的进步,不仅提高了生产效率,还推动了行业的可持续发展,本文将围绕美国纺织厂机器的主题,探讨其现代化与效率提升的相关内容。

机器设备介绍

纺织生产线中的主要机器设备

在纺织生产线上,主要使用的机器设备包括但不限于:

(1)高速织布机:用于大规模生产高质量的织物。

(2)自动裁剪机:用于精确裁剪不同尺寸的布料。

(3)自动缝纫机:用于自动化缝合衣物。

(4)自动打包机:用于快速打包成捆的纺织品。

机器技术的先进性

这些机器设备采用了先进的自动化技术,包括机器人技术、大数据分析、人工智能等,大大提高了生产效率和产品质量,自动裁剪机可以通过机器学习算法自动识别布料尺寸,提高了裁剪的精确度和效率。

案例分析

以某美国纺织厂为例,展示机器设备在现代纺织生产中的实际应用和效果。

高效织布机

该纺织厂采用了高效织布机,实现了大规模生产高质量织物的目标,该织布机采用了先进的自动化技术,能够根据不同的布料类型和尺寸自动调整工作参数,大大提高了生产效率,该织布机还具有较高的自动化程度,减少了人工干预,降低了生产成本。

自动化缝纫机应用

该纺织厂还采用了自动化缝纫机,实现了自动化缝合衣物,该缝纫机可以通过大数据分析自动识别衣物尺寸和形状,从而精确缝合衣物,该缝纫机还具有较高的灵活性,可以根据不同的生产线需求进行快速调整和升级。

现代机器技术的影响与意义

现代机器技术在纺织行业中的应用带来了许多积极的影响和意义,现代机器技术提高了生产效率和质量,降低了生产成本,现代机器技术推动了行业的可持续发展,有利于环境保护和资源节约,现代机器技术也为工人提供了更好的工作环境和更高的职业发展空间。

美国纺织厂在机器设备方面取得了显著的进步,不仅提高了生产效率和质量,还推动了行业的可持续发展,随着科技的不断发展,纺织行业将继续面临新的挑战和机遇,纺织厂需要不断更新和升级机器设备,提高生产效率和产品质量,以适应市场的变化和发展需求,纺织厂还需要注重环境保护和资源节约,推动行业的可持续发展。

Articles related to the knowledge points of this article:

The Efficient Operation of Textile Factory Water Shroud Fan System

The Transformation of Yangquan Mu County Textile Factory