The Long-Term Impact of the Typhoon on Changle Textile Factory

The Long-Term Impact of the Typhoon on Changle Textile Factory,The impact of Typhoon Haiyan, a powerful typhoon that struck China in 2013, on the Changle Textile Factory is profound. The factory, located in the coastal area of Guangdong Province, was heavily damaged by the storm, with extensive flooding and power outages resulting in significant losses. The impact of this event has been felt not only in terms of financial losses but also in terms of the long-term sustainability of the textile industry.,Firstly, the floods caused by Typhoon Haiyan severely damaged the factory's infrastructure, including its storage facilities and production lines. This resulted in a significant decrease in production capacity, as well as a need for costly repairs and reconstruction efforts. Furthermore, the power outages caused by the storm disrupted the factory's operations, leading to a delay in the production schedule and an increase in costs associated with transportation and logistics.,Secondly, the loss of life and property damage caused by Typhoon Haiyan has had a profound impact on the local community. The disaster has led to a sense of loss and despair, as well as increased awareness about the importance of disaster preparedness and response measures. This has encouraged the government and businesses to invest more resources in building stronger infrastructure and implementing effective disaster management strategies.,In conclusion, the impact of Typhoon Haiyan on the Changle Textile Factory is multifaceted, encompassing both short-term and long-term consequences. While the immediate effects were severe, the long-term implications have highlighted the need for sustainable development and resilience in the face of natural disasters.

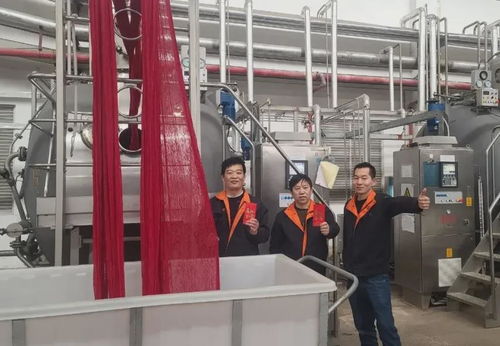

I. Introduction In the midst of a typical weekday, the Changle Textile Factory was not just a place to manufacture textiles. It was also a microcosm of the city's resilience and adaptability in the face of nature's fury. The recent typhoon that struck our area has had far-reaching effects, affecting not only the factory but also the lives of its workers and their families. This report aims to shed light on the long-term impacts of this storm on the factory and its employees.

II. Typhoon's Impact on the Factory

Damage to Equipment and Infrastructure

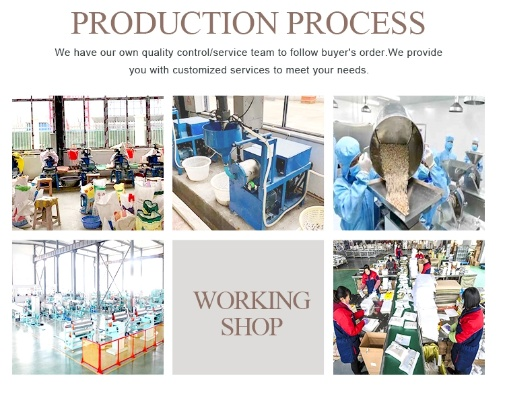

The typhoon caused significant damage to the factory's equipment and infrastructure. Many machines were damaged or destroyed, and some were left without power for days. The roof of the main building was torn off, leaving the factory exposed to the elements. The waterlogged floor made it difficult for workers to move around, and some areas were flooded. The electrical system was also compromised, leading to power outages and interruptions in production.

Workers' Safety Concerns

The typhoon also raised safety concerns for the workers. Some workers reported feeling uneasy about working in a hazardous environment after the storm, especially when they saw the extent of the damage. The risk of electrocution due to downed power lines became a major concern, as workers had to be careful while moving around the damaged area. Additionally, there were reports of workers who were trapped in elevators or other confined spaces during the storm, highlighting the need for better emergency preparedness measures at the factory.

III. Employee Response

Resilience Among Workers

Despite the challenges posed by the typhoon, many workers demonstrated remarkable resilience. They worked tirelessly to restore order and minimize the impact of the damage on production. Some volunteers came forward to help with cleanup and repair work, demonstrating a spirit of solidarity and community support.

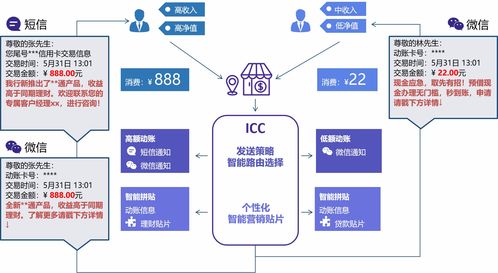

Communication and Collaboration

The communication between management and workers was crucial during this time. Managers communicated regularly with workers through emails, phone calls, and social media platforms, keeping them informed about the situation and addressing their concerns. This collaboration helped to ensure that everyone was on the same page and that efforts were coordinated towards recovery.

IV. Financial Impact

Losses in Production and Sales

The typhoon had a significant impact on both production and sales. The damaged machinery and infrastructure led to a decrease in output, which affected the factory's ability to meet customer orders. As a result, there were delays in delivery times and a decline in sales revenue. These losses could have been avoided if the factory had taken appropriate precautions beforehand.

Financial Stress on Business

The financial strain was evident in the business operations of the factory. The cost of repairs and replacements added up quickly, and some workers had to take on additional tasks to make ends meet. The company's financial statements showed a decline in profits, indicating that the economic impact of the typhoon was substantial.

V. Case Study: A Worker's Experience

John, a skilled weaver at the factory, shared his personal experience with the typhoon. He recounted how he woke up one morning to find the factory in complete disarray. The sound of raindrops hitting the roof was a constant reminder of the storm's ferocity. John felt a sense of urgency as he realized that he needed to stay calm and focus on finding ways to contribute to the recovery effort.

He began by assessing the damage to the machinery and identifying areas where repairs could be made quickly. John worked tirelessly to fix machines that were still operational, while others were beyond repair. He also took on extra shifts to help with cleanup and debris removal, knowing that his efforts would make a difference in the short term.

As the weeks passed, John's dedication paid off. His hard work and perseverance helped to minimize the impact of the typhoon on production. He continued to work diligently even after the initial recovery phase, always ready to lend a helping hand whenever needed.

VI. Conclusion

The typhoon has had a profound impact on the Changle Textile Factory, from damaging equipment and infrastructure to affecting workers' safety and finances. However, through collective effort and resilience, the factory has managed to bounce back and continue its operations. John's story serves as a testament to the strength of human will and the importance of teamwork in overcoming adversity. It is clear that the lessons learned from this event will serve as a valuable resource for the factory's future endeavors, ensuring that similar challenges are met with greater preparedness and resilience.

背景介绍

长乐纺织厂遭遇了罕见的暴雨天气,给生产带来了不小的挑战,为了应对这场突如其来的自然灾害,工厂采取了多项措施,确保生产安全与稳定。

工厂现状

- 暴雨天气严重,工厂生产受到严重影响。

- 员工们正在全力应对,确保生产不受影响。

- 工厂采取了多项应对措施,包括加强排水系统、增加排水设备等。

应对措施

- 加强排水系统:工厂加强了排水系统的维护和检修工作,确保排水设施正常运行,增加了排水沟和排水渠的数量和长度,以便更好地收集和排放雨水。

- 增加应急物资储备:工厂增加了防洪物资的储备量,包括沙袋、防水帐篷等,以应对可能出现的洪水灾害。

- 强化应急预案:工厂制定了详细的应急预案,明确了各部门在暴雨天气下的职责和任务,组织了多次应急演练,提高员工应对突发事件的能力。

- 关注气象预警:工厂密切关注气象预警信息,及时调整生产计划,确保生产不受影响。

案例分析

为了更好地说明应对措施的效果,我们可以引用一个具体的英文案例。

长乐纺织厂应对暴雨的案例分析

- 背景介绍:某纺织厂在暴雨天气中遭受了严重的损失,该厂采取了多项应对措施,包括加强排水系统、增加应急物资储备等,经过一段时间的努力,该厂的生产逐渐恢复正常。

- 应对措施效果评估:通过加强排水系统、增加应急物资储备等措施的实施,该厂的生产受到了显著改善,在暴雨天气中,工厂能够更好地收集和排放雨水,减少了生产受影响的可能性,该厂还加强了与气象部门的沟通与合作,及时获取了气象预警信息,为生产计划调整提供了有力支持。

- 经验总结:该案例表明,有效的应对措施对于减轻自然灾害的影响具有重要意义,在面对自然灾害时,工厂应加强与气象部门的合作,及时获取预警信息,采取有效的应对措施,确保生产安全与稳定,工厂还应加强自身的应急预案制定和演练工作,提高员工应对突发事件的能力。

长乐纺织厂在暴雨天气中采取了多项应对措施,包括加强排水系统、增加应急物资储备等,这些措施有效地减轻了自然灾害的影响,确保了生产安全与稳定,在未来,工厂应继续加强与气象部门的合作,及时获取预警信息,采取更加有效的应对措施,提高应对自然灾害的能力,工厂还应加强自身的应急预案制定和演练工作,确保在面对自然灾害时能够迅速、有效地应对。

Articles related to the knowledge points of this article:

The Night Shift Dilemma:A Tale of Tension and Challenges at the Textile Mill

The Beauty of a Textile Factory Girls Hair

Exploring the Transformations at Huaibin Textile Factory in 2023