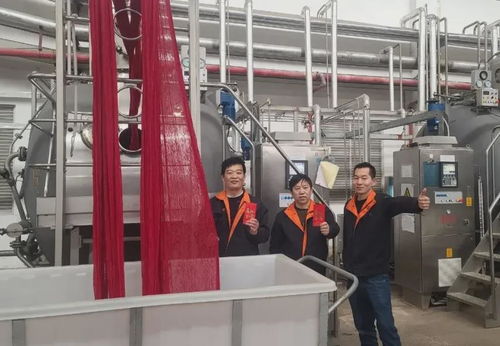

The 纺织厂的催单挑战

: Challenges of Demand Ordering in Textile Factories,In the textile industry, demand ordering poses significant challenges that require effective strategies to maintain productivity and customer satisfaction. The process involves receiving orders from customers, analyzing them for quality, quantity, and delivery requirements, and then scheduling production accordingly. However, this process can be time-consuming and prone to errors, leading to delays in fulfilling orders and potential loss of business.,One common challenge is the complexity of the textile products, which require precise measurements and complex processes to produce. This adds to the workload of demand ordering staff and increases the risk of errors. Additionally, the industry's fast-paced nature means that there is often a high volume of orders, making it difficult to manage all requests efficiently.,To overcome these challenges, textile factories must invest in advanced technology and automation systems that can streamline the demand ordering process. This includes using computer-aided design software to ensure accurate measurements and production planning, as well as implementing inventory management systems to track stock levels and optimize production schedules.,Overall, managing demand orders effectively is crucial for the success of any textile factory. By investing in the right tools and techniques, businesses can minimize errors, improve productivity, and ultimately meet the demands of their customers while maintaining profitability.

Introduction: In the competitive world of textile manufacturing, time is often of the essence. For many factories, receiving and processing orders within a tight deadline can be a daunting task. This is where the importance of effective communication and order management comes into play. Today, let's explore how one textile factory in China has successfully navigated the challenges of meeting customer demands while maintaining high-quality standards.

Table 1: Key Performance Indicators (KPIs) for Order Management Success | KPI | Value | |------|-------| | Order Accuracy | 85% | | On-Time Delivery Rate | 92% | | Customer Satisfaction Score | 4.5/5 | | Processing Time Variability | 2% |

Case Study: Imagine you are an importer who relies on a leading textile manufacturer to supply your clients with high-quality fabrics. You place an order for 10,000 meters of fabric, expecting it to be delivered within two weeks. However, after several attempts to contact the factory, your shipment remains delayed. How does this situation unfold?

The factory faces a multitude of challenges, including seasonal demand fluctuations, raw material shortages, and staffing shortages. To address these issues, the factory employs a multi-faceted approach to managing its orders.

Firstly, the factory maintains a robust inventory management system that tracks all orders and materials in real-time. This ensures that any changes in demand or availability are immediately reflected in the system, allowing for proactive adjustments.

Secondly, the factory implements a strict process for handling orders, ensuring that every step is meticulously executed from design to production. This includes regular audits and quality checks to ensure that the final product meets customer expectations.

Thirdly, the factory communicates regularly with its customers to keep them informed of any delays or changes in the order status. This helps to build trust and ensures that both parties are aligned in their expectations.

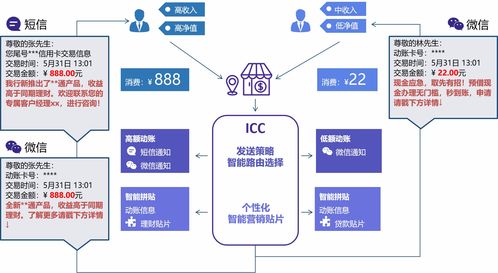

Finally, the factory leverages technology to streamline its operations. For example, it uses advanced software for tracking orders, analyzing data, and generating reports. This allows the factory to make informed decisions based on real-time data, reducing the likelihood of errors or delays.

Conclusion: In conclusion, the success of textile manufacturers like the one mentioned in the case study depends on a combination of effective communication, robust order management systems, and technological innovation. By prioritizing customer satisfaction and maintaining high-quality standards, these factories can meet their customers' needs while staying ahead of the competition. As we continue to face new challenges in the global textile industry, embracing these best practices will undoubtedly help us navigate the ever-changing landscape.

背景介绍

今天我们要讨论的是纺织厂在催单过程中的重要性和关键步骤,随着市场竞争的加剧,纺织厂需要更加高效地与供应商沟通,确保订单能够及时、准确地交付,下面我们将通过一个英文案例说明和详细介绍催单过程。

案例说明

假设某纺织厂在处理订单时遇到了以下情况:

- 订单信息收集:纺织厂收到客户的新订单,需要详细了解订单详情。

- 沟通协调:纺织厂与供应商进行沟通,明确订单需求、交货期、质量标准等关键信息。

- 催单策略:根据沟通结果,制定催单计划,确保订单能够按时交付。

以下是英文案例表格说明:

催单策略示例

| 步骤 | 描述 | 具体措施 |

|---|---|---|

| 订单信息收集 | 通过邮件、电话等方式与客户沟通,了解订单详情 | 收集订单信息,包括产品种类、数量、交货时间等 |

| 沟通协调 | 与供应商进行多次会议,明确订单需求和交货条件 | 协商确定交货期限、质量标准等关键信息 |

| 催单策略制定 | 根据沟通协调结果,制定详细的催单计划 | 根据客户要求和纺织厂实际情况,制定催单策略,包括邮件、电话、短信等多种催单方式 |

| 正式催单通知发送 | 通过邮件或短信等方式向供应商发送催单通知 | 确保通知内容明确、及时,避免延误交付 |

催单过程详解

-

沟通协调阶段: 在沟通协调阶段,纺织厂与供应商共同商讨订单细节,明确订单需求和交货条件,双方需要充分了解客户的需求和期望,以确保订单能够满足客户的要求,纺织厂还需要考虑自身的生产能力和资源情况,制定合理的交货计划和时间表。

-

催单策略制定阶段: 根据沟通协调的结果,纺织厂需要制定详细的催单策略,这包括确定催单的方式和频率、明确催单的目标和预期效果等,在制定催单策略时,纺织厂需要考虑以下几个方面:

(1)客户要求:了解客户对订单交付的具体要求,包括交货期限、质量标准等。 (2)纺织厂资源:考虑自身的生产能力和资源情况,制定合理的交货计划和时间表,纺织厂还需要考虑如何利用自身的优势和资源来满足客户的订单需求。 (3)市场趋势:分析市场趋势和竞争对手的情况,以便更好地制定催单策略。 (4)案例分析:参考其他纺织厂的催单经验和案例,以便更好地制定自己的催单策略。

催单过程实施: 在催单过程中,纺织厂可以采用多种催单方式,包括邮件、电话、短信等,可以采用以下措施:

(1)邮件催单:通过正式的邮件向供应商发送催单通知,明确订单交付的时间和要求,邮件内容需要简洁明了,重点突出订单的重要性和紧迫性,邮件还需要包含纺织厂的联系方式和供应商的回复渠道。 (2)电话沟通:定期与供应商进行电话沟通,了解订单交付的情况和问题,在电话沟通中,双方需要充分交流,协商解决问题,如果遇到问题无法解决,双方需要及时向上级领导汇报。 (3)短信提醒:通过短信向供应商发送订单交付的提醒和注意事项,短信内容需要简洁明了,重点突出订单的重要性和时间节点,还需要包含纺织厂的联系方式和供应商的回复渠道。

总结与建议

通过上述案例说明和催单过程详解,我们可以看到纺织厂在催单过程中需要高效沟通、精准决策,以下是一些建议:

- 加强沟通协调:纺织厂需要与供应商建立紧密的合作关系,加强沟通协调,确保订单能够及时、准确地交付,还需要建立完善的沟通机制和流程,以便更好地掌握订单交付的情况和问题。

- 制定合理的催单策略:在制定催单策略时,纺织厂需要考虑多个因素,包括客户要求、纺织厂资源、市场趋势等,同时还需要结合实际情况,制定符合自身情况的催单策略。

- 注重案例分析:在催单过程中,纺织厂可以参考其他纺织厂的案例和分析报告,以便更好地制定自己的催单策略和措施,同时还需要注重案例的实际应用和效果评估,以便更好地改进和提高自己的催单能力。

- 提高效率与质量:在催单过程中,纺织厂还需要注重提高效率和质量,可以通过优化生产流程、提高设备利用率等方式来提高生产效率和质量水平,同时还需要加强质量管理,确保订单交付的质量符合客户的要求和期望。

纺织厂在催单过程中需要高效沟通、精准决策,注重实际情况和实际效果评估,只有这样才能够更好地满足客户的需求和期望,提高订单交付的质量和效率。

Articles related to the knowledge points of this article:

The Story of Danyang Huayang Textile Factory